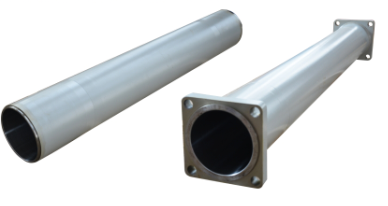

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

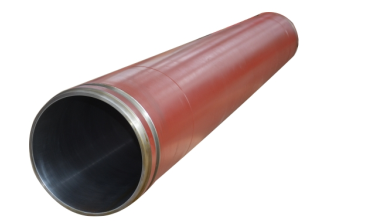

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q:Are there any specific guidelines for the installation of hydraulic filters or strainers in concrete pump spare parts?

- Specific guidelines exist for the installation of hydraulic filters or strainers in concrete pump spare parts. These guidelines should be followed to ensure proper installation and functionality of the filter or strainer. Here are some important considerations: 1. Size and Compatibility: It is crucial to choose a hydraulic filter or strainer that is the correct size and compatible with the specific make and model of the concrete pump. Failure to do so can lead to inadequate filtration or damage to the hydraulic system. 2. Location: The filter or strainer should be installed in a location that allows for easy access and maintenance. It should be positioned in a way that facilitates proper filtration without obstructing the flow of hydraulic fluid. 3. Mounting: To prevent movement or vibration during operation, the filter or strainer must be securely mounted. It is essential to adhere to the manufacturer's instructions regarding proper mounting techniques and torque specifications. 4. Orientation: Pay attention to the recommended orientation of the filter or strainer. Some filters have specific flow direction requirements, and incorrect installation can impact their performance and efficiency. 5. Protection: Consider adding extra protection, such as a guard or shield, to shield the filter or strainer from external factors like debris or impacts. This can extend the lifespan and effectiveness of the filter. 6. Maintenance: Regularly inspecting and cleaning the filter or strainer is important to ensure optimal functioning. Adhere to the manufacturer's recommended maintenance schedule and procedures for replacement or cleaning to maintain efficient filtration. Remember to consult the manufacturer's instructions and guidelines for the specific hydraulic filter or strainer being installed, as they may have unique recommendations or requirements for their product.

- Q:What is the role of a concrete pump hopper grate pin retainer?

- A concrete pump hopper grate pin retainer plays a crucial role in ensuring the safety and functionality of a concrete pump. It is responsible for securing the grate pins in place, which in turn helps to hold the hopper grate firmly in position. The hopper grate is an important component of a concrete pump as it acts as a barrier, preventing any debris or foreign objects from entering the hopper and potentially causing damage to the pump or interfering with the concrete mixing process. The grate pins, located on the sides of the hopper, help to keep the grate securely in place. The concrete pump hopper grate pin retainer is specifically designed to hold the grate pins firmly and prevent them from becoming loose or dislodged during the pumping operation. By keeping the grate securely in position, it ensures that the hopper remains free from any unwanted materials and maintains a smooth and uninterrupted flow of concrete. Furthermore, the pin retainer also helps to prevent potential accidents or injuries by minimizing the risk of the grate coming loose or falling off during operation. This is particularly important when working in construction sites or other high-risk environments, where the safety of workers and equipment is of utmost importance. In summary, the role of a concrete pump hopper grate pin retainer is to provide stability and security to the hopper grate by holding the grate pins firmly in place. It ensures the smooth functioning of the concrete pump by preventing any debris from entering the hopper and maintains a safe working environment by minimizing the risk of accidents or injuries.

- Q:Can I get spare parts for concrete pump accessories like remote control systems?

- Yes, you can get spare parts for concrete pump accessories like remote control systems. Many manufacturers and suppliers of concrete pump accessories offer a range of spare parts for their products. These spare parts may include components for remote control systems such as buttons, switches, sensors, batteries, and transmitters. It is advisable to contact the manufacturer or supplier directly to inquire about the availability of spare parts for the specific model of remote control system you have. They will be able to provide you with the necessary information and assist you in obtaining the required spare parts.

- Q:What is the concrete delivery pump?

- Another is a pump consisting of a pump body mounted on an automobile chassis and fitted with retractable or bent cloth poles.

- Q:What is the purpose of a concrete pump accumulator?

- The concrete pump accumulator serves the purpose of storing energy and ensuring a continuous and uniform flow of concrete while pumping. It acts as a intermediary between the pump and the delivery line, guaranteeing a smooth and uninterrupted delivery of concrete. The accumulator functions by compressing air or nitrogen, which is then utilized to propel the concrete through the pipeline when the pump is not actively operating. This aids in maintaining pressure and preventing any obstructions or irregularities in the flow of concrete. Additionally, the accumulator can reduce the wear and tear on the pump by absorbing pressure fluctuations and providing a more controlled and consistent flow of concrete. In summary, the concrete pump accumulator aims to enhance the efficiency, reliability, and performance of the pumping process.

- Q:Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Yes, there are specific cleaning and maintenance procedures for concrete pump spare parts. For cleaning, it is important to remove any concrete buildup or residue from the spare parts regularly. This can be done by using a high-pressure water jet or by soaking the parts in a cleaning solution specifically designed for concrete. It is essential to follow the manufacturer's instructions when using cleaning agents to ensure the safety and effectiveness of the cleaning process. In addition to cleaning, regular maintenance is necessary to ensure the longevity and proper functioning of concrete pump spare parts. This includes inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if necessary. Lubrication of moving parts, such as bearings or pistons, should also be done as per the manufacturer's recommendations. It is important to note that different concrete pump spare parts may require specific cleaning and maintenance procedures. Therefore, it is advisable to refer to the manufacturer's guidelines or consult with a qualified technician to determine the appropriate cleaning and maintenance procedures for each specific part.

- Q:How does a concrete pump clamp work?

- A concrete pump clamp is a device used to secure and hold the different components of a concrete pump system together during operation. It acts as a connector between the pipes, hoses, and couplings in the system, ensuring a tight and leak-free connection. The clamp generally consists of two halves that are tightened together using bolts, creating a strong grip around the components. This tight grip prevents any movement or separation of the pipes and hoses, allowing for efficient and safe concrete pumping.

- Q:Can concrete pump spare parts be pre-assembled or pre-tested before installation?

- Concrete pump spare parts can undergo pre-assembly and pre-testing prior to installation. This allows for quality control measures to be implemented before the actual installation takes place, ensuring that any defects or issues with the parts can be identified and resolved before they are put into the concrete pump. Furthermore, pre-testing the spare parts guarantees their functionality and compatibility with the pump system, enabling any necessary adjustments or modifications to be made in advance. By engaging in these practices, the risk of complications during the installation process is reduced, resulting in a smooth and efficient operation of the pump system.

- Q:How often should hopper agitator motors be inspected or replaced in a concrete pump?

- The frequency at which hopper agitator motors should be inspected or replaced in a concrete pump depends on various factors such as the usage intensity, operating conditions, and maintenance practices. However, as a general guideline, it is recommended to inspect hopper agitator motors regularly, at least once every three to six months. Regular inspections can help identify any signs of wear and tear, damage, or malfunctioning in the motor. This can include issues such as abnormal noise, excessive vibrations, overheating, or reduced performance. Additionally, it is important to check for any loose or worn out components, such as belts, pulleys, or bearings, which could affect the motor's efficiency and lifespan. If any significant issues or malfunctions are detected during the inspection, it may be necessary to replace the hopper agitator motor. The decision to replace the motor should be based on the severity of the problem, the age of the motor, and the cost-effectiveness of repairs compared to a replacement. Besides regular inspections, it is crucial to follow the manufacturer's recommendations for maintenance and lubrication of the hopper agitator motor. Proper maintenance practices can extend the lifespan of the motor and minimize the need for replacement. Ultimately, the specific frequency of inspections and replacement of hopper agitator motors in a concrete pump should be determined based on the specific circumstances and conditions in which the pump is operated, in consultation with the manufacturer's guidelines and recommendations.

- Q:How do I properly maintain and replace hydraulic pumps in concrete pump spare parts?

- To ensure the smooth functioning and long life of your equipment, it is crucial to properly maintain and replace hydraulic pumps in concrete pump spare parts. Here are some steps that can assist you in this process: 1. Conduct Regular Inspections: Before and after each use, visually inspect the hydraulic pump to detect any signs of wear, leaks, or damage. Additionally, check for loose bolts, damaged seals, or excessive noise during operation. 2. Adhere to Manufacturer's Guidelines: Consult the manufacturer's guidelines and recommendations regarding the maintenance and replacement of hydraulic pumps. They will provide specific instructions concerning the frequency of maintenance, lubrication, and replacement intervals. 3. Ensure Proper Lubrication: Smooth operation of hydraulic pumps requires proper lubrication. Regularly check the oil levels and refill if necessary. Utilize the recommended oil or hydraulic fluid as specified by the manufacturer. Adhere to the guidelines regarding the frequency of oil changes. 4. Maintain Regular Cleaning: Keep the hydraulic pump and its components free from debris, dust, and dirt. Employ a clean cloth or compressed air to eliminate any accumulated contaminants. This practice will help prevent damage and minimize the likelihood of clogs or blockages. 5. Replace Worn Parts: Over time, certain components of the hydraulic pump may wear out and necessitate replacement. Maintain a stock of spare parts, including seals, gaskets, and filters, to promptly replace any worn or damaged components. 6. Seek Professional Assistance: If you are uncertain about any aspect of maintaining or replacing hydraulic pumps, it is advisable to consult a professional technician or the manufacturer. They possess the expertise and knowledge to guide you through the process and ensure the best maintenance and replacement practices. Remember, regular maintenance and timely replacement of hydraulic pumps in concrete pump spare parts will not only prolong the lifespan of your equipment but also ensure safe and efficient operation on construction sites.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM LENGTH:1545MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords