PUMPING CYLINDER(PM) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

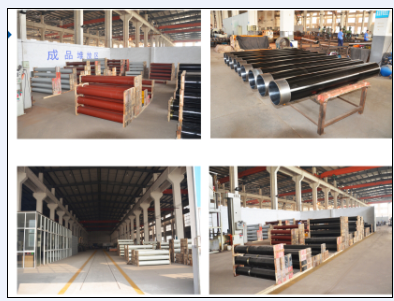

Product Description:

The Concrete Pump Delivery Cylinder DN230*1600normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN230*1600 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN230*1600can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN180*1545

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN230*1600Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN230*1600?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN180*1545?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN230*1600according to customers request?

A4: Yes, we can produce Cylinders DN230*1600according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: How can a faulty concrete pump cylinder affect the pumping process?

- A faulty concrete pump cylinder can adversely affect the pumping process in several ways. Firstly, it can lead to a decrease in pumping efficiency, resulting in slower and less productive pumping. Secondly, it can cause leaks, leading to wastage of concrete and potential damage to the surrounding area. Additionally, a faulty cylinder can cause inconsistent flow of concrete, leading to an uneven distribution and poor quality of the poured concrete. Overall, a faulty concrete pump cylinder can significantly impact the effectiveness and quality of the pumping process.

- Q: How can I extend the lifespan of my concrete pump spare parts?

- To extend the lifespan of your concrete pump spare parts, there are several key steps you can take: 1. Regular maintenance: Implement a comprehensive maintenance schedule for your concrete pump, including the spare parts. This should include regular inspections, cleaning, and lubrication of the parts. By identifying and addressing any issues early on, you can prevent further damage and extend the lifespan of the parts. 2. Use high-quality spare parts: Invest in high-quality spare parts from reputable manufacturers. Cheaper alternatives may save you money initially, but they tend to have shorter lifespans and may require frequent replacements. Opting for quality parts will ensure durability and longevity. 3. Proper storage: Store your spare parts in a clean, dry, and well-organized environment. Exposure to moisture, extreme temperatures, and dirt can deteriorate the parts over time. Consider using protective covers or cases to shield the parts from dust and other contaminants. 4. Train operators: Proper operation of the concrete pump is crucial to preventing unnecessary wear and tear on the spare parts. Ensure that your operators are well-trained and follow the manufacturer's guidelines for usage and maintenance. Discourage any misuse or improper handling of the equipment, as this can lead to premature wear of the spare parts. 5. Regular cleaning: Keep your concrete pump clean by regularly removing any concrete buildup. The accumulation of hardened concrete can cause additional strain on the spare parts and lead to premature failure. Use appropriate cleaning methods and tools to ensure thorough removal without causing damage to the parts. 6. Timely repairs: Address any issues or damage to the spare parts as soon as they are identified. Ignoring or delaying repairs can worsen the problem and potentially cause damage to other components. Regularly inspect the spare parts for signs of wear, such as cracks, leaks, or excessive vibration, and promptly address any concerns. 7. Monitor usage and performance: Keep track of the usage and performance of your concrete pump and spare parts. Regularly monitor the wear and tear of the parts and the overall performance of the pump. Analyze any patterns or trends that may indicate potential problems and take corrective actions to prevent further damage. By following these steps, you can significantly extend the lifespan of your concrete pump spare parts, ensuring optimal performance and reducing the need for frequent replacements.

- Q: How can a faulty accumulator affect the pumping efficiency?

- A faulty accumulator can negatively impact pumping efficiency by causing inconsistent pressure and flow rates in the system. This can lead to excessive energy consumption, reduced overall performance, and potential damage to the pump and other components.

- Q: How does a hopper agitator blade ensure smooth concrete flow?

- A hopper agitator blade ensures smooth concrete flow by constantly mixing and agitating the concrete inside the hopper. This prevents the concrete from settling or forming clumps, ensuring a consistent and even flow of the material. The agitation action of the blade also helps to break up any air pockets that may be present in the concrete, resulting in a more uniform and high-quality mixture.

- Q: What do these types of concrete pumps mean?

- After the 16 is the motor power kW (landlord 16 seems to have a mistake, usually 110) or the manufacturer's serial number.

- Q: How can a faulty battery affect the operation of the pump?

- A faulty battery can significantly affect the operation of a pump. Firstly, a faulty battery may not provide enough power to the pump, resulting in slow or weak pumping action. This can impact the pump's ability to generate the necessary pressure or flow rate, leading to inefficient or ineffective operation. Additionally, a faulty battery may cause intermittent power supply to the pump. This can result in inconsistent pumping action, with the pump starting and stopping sporadically. Such interruptions can create inefficiencies, reduce the pump's performance, and potentially cause damage to the equipment or system being operated. Furthermore, a faulty battery may not hold a charge for an extended period. This can limit the pump's runtime, requiring frequent recharging or replacement of the battery. In scenarios where a pump is needed for continuous or prolonged usage, a faulty battery can disrupt operations, leading to downtime and reduced productivity. Moreover, a faulty battery can also impact the overall lifespan of the pump. If the battery does not provide the necessary power consistently, the pump may experience strain or excessive wear, potentially shortening its operational life. Overall, a faulty battery can have various adverse effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited runtime, potential damage, and decreased equipment lifespan. Regular maintenance and timely replacement of faulty batteries are crucial to ensure optimal pump performance and longevity.

- Q: What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The installation and replacement of concrete pump spare parts come with various potential risks. Improper installation is a key risk, as it can cause leaks, reduced performance, and even equipment failure. This not only leads to expensive repairs but also poses a safety threat to workers and those nearby. Another risk is the use of counterfeit or low-quality spare parts. These parts may not meet the necessary standards, compromising the integrity and functionality of the concrete pump. This increases the likelihood of equipment failure and accidents. Moreover, the installation and replacement process may involve operating heavy machinery like cranes or forklifts, which can be dangerous if not done correctly. Inadequate precautions can result in accidents, injuries, or damage to the equipment or surrounding structures. Additionally, concrete pump spare parts may contain hazardous materials or substances. Workers must be aware of the risks associated with handling and disposing of these materials, such as exposure to harmful chemicals or environmental contamination. Lastly, there is a risk of delays and downtime during the installation and replacement process. If spare parts are not readily available or compatibility issues arise, equipment may be inoperable for extended periods. This can cause project delays, increased costs, and potential financial losses. To mitigate these risks, it is crucial to provide proper training and supervision to workers involved in the installation and replacement of concrete pump spare parts. Using genuine and high-quality spare parts from reputable suppliers can also reduce the risk of equipment failure. Regular inspections, maintenance, and adherence to safety protocols are essential to minimize potential risks associated with this process.

- Q: When concrete is poured, how high can the concrete pump be put?

- When the floor height exceeds the applicable height of the automobile pump, the ground pump (stationary pump) is used to pour and grind the concrete, and the height of the pump can reach more than 100 meters to two hundred meters

- Q: Can a concrete pump pipe be repaired or should it be replaced?

- A concrete pump pipe can typically be repaired rather than replaced, depending on the extent of the damage.

- Q: Can I get spare parts for concrete pump accessories like remote control systems?

- Yes, you can get spare parts for concrete pump accessories like remote control systems. Many manufacturers and suppliers of concrete pump accessories offer a range of spare parts for their products. These spare parts may include components for remote control systems such as buttons, switches, sensors, batteries, and transmitters. It is advisable to contact the manufacturer or supplier directly to inquire about the availability of spare parts for the specific model of remote control system you have. They will be able to provide you with the necessary information and assist you in obtaining the required spare parts.

Send your message to us

PUMPING CYLINDER(PM) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords