PUMPING CYLINDER(PM) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

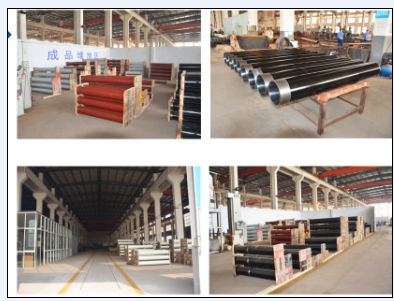

Product Description:

The Concrete Pump Delivery Cylinder DN200*1600 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN200*1600 is a concrete pumping for combined use with other concrete pumps in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder DN200*1600 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN200*1600

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN200*1600 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN200*1600 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN200*1600 ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN200*1600 according to customers request?

A4: Yes, we can produce Cylinders DN200*1600 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: What are the signs of wear and tear in concrete pump spare parts?

- Some signs of wear and tear in concrete pump spare parts include cracks or fractures in the components, excessive vibration or noise during operation, decreased performance or efficiency, leaks or drips from seals or connectors, and visible corrosion or rust on metal parts. Additionally, worn-out or damaged rubber gaskets, seals, or O-rings can also indicate the need for replacement.

- Q: Can concrete pump spare parts be inspected or certified by third-party organizations?

- Yes, concrete pump spare parts can be inspected and certified by third-party organizations. These organizations are typically independent and have the expertise and resources to evaluate the quality, performance, and safety of the spare parts. They follow specific industry standards and guidelines to conduct inspections, tests, and audits to determine if the spare parts meet the necessary requirements. The certification provided by these third-party organizations gives assurance to customers that the spare parts have been assessed and found to be in compliance with the applicable standards. This helps to enhance trust and confidence in the products, ensuring that they are reliable and suitable for use in concrete pumps.

- Q: Are there any specific guidelines for the installation of hopper components or agitators in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of hopper components or agitators in concrete pump spare parts. These guidelines typically include instructions on proper alignment, securing of bolts, lubrication, and ensuring all components are properly connected. It is important to follow these guidelines to ensure safe and efficient operation of the concrete pump.

- Q: Can concrete pump spare parts be used interchangeably between different pump brands or models?

- No, concrete pump spare parts cannot be used interchangeably between different pump brands or models. Each brand and model of concrete pump has its own unique design and specifications, requiring specific spare parts that are compatible with that particular pump. Using interchangeable parts can lead to ineffective functioning and potential damages to the pump. It is crucial to use the correct spare parts recommended by the manufacturer to ensure optimal performance and longevity of the pump.

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts. It is important to follow the manufacturer's instructions and recommendations provided with the seal kits or O-rings. The guidelines typically include steps such as cleaning and preparing the installation area, ensuring proper alignment and fit, utilizing appropriate lubrication, and applying the correct amount of torque during installation. Adhering to these guidelines helps ensure proper functioning and longevity of the concrete pump spare parts.

- Q: How can one determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts?

- Determining the appropriate viscosity and temperature range for lubricants used in concrete pump spare parts requires the consideration of multiple factors. Below are some steps that can assist in determining the suitable viscosity and temperature range: 1. Refer to the manufacturer's recommendations: To begin with, consult the specific guidelines or recommendations provided by the manufacturer for the concrete pump spare parts. The manufacturer may specify the required viscosity and temperature range for the lubricants used in their equipment. 2. Gain a clear understanding of the operating conditions: It is essential to have a comprehensive understanding of the operating conditions in which the concrete pump spare parts will be utilized. Factors such as ambient temperature, pump speed, load, and pressure should be taken into account. These factors can significantly impact the viscosity requirements and temperature range of the lubricant. 3. Assess the performance characteristics of the lubricant: Different lubricants possess distinct performance characteristics that make them suitable for particular applications. Look for lubricants specifically formulated for heavy-duty tasks, offering excellent wear protection and displaying good thermal stability. These performance characteristics ensure that the lubricant can endure the demanding conditions of a concrete pump. 4. Viscosity requirements: The viscosity of the lubricant plays a crucial role in ensuring proper lubrication and safeguarding of the concrete pump spare parts. Heavy-duty applications generally require higher viscosity lubricants, while lighter loads may be better suited with lower viscosity lubricants. The viscosity requirements may also differ depending on the specific pump parts, such as bearings, gears, or seals. Referring to the manufacturer's guidelines and seeking advice from lubricant suppliers can help determine the ideal viscosity range for the concrete pump spare parts. 5. Consider the temperature range: The temperature range within which the concrete pump operates is another significant aspect to consider. Lubricants should be capable of maintaining their viscosity and performance across the expected temperature range. Extreme temperatures can cause lubricants to lose their effectiveness, potentially leading to equipment damage or failure. Consequently, it is important to select lubricants with a temperature range suitable for the operating conditions of the concrete pump. 6. Consult with experts: If uncertainty persists regarding the appropriate viscosity and temperature range, it is advisable to seek advice from lubricant manufacturers, suppliers, or industry experts. They can offer valuable insights and recommendations based on their expertise and experience with concrete pump spare parts. By adhering to the manufacturer's recommendations, comprehending the operating conditions, evaluating the lubricant's performance characteristics, and seeking professional advice, it becomes possible to determine the correct viscosity and temperature range for lubricants used in concrete pump spare parts. This will ensure optimal lubrication and extend the lifespan of the equipment.

- Q: How can one determine the correct pressure and flow rating for hydraulic components in concrete pump spare parts?

- To determine the correct pressure and flow rating for hydraulic components in concrete pump spare parts, several factors need to be considered: 1. Manufacturer's specifications: Review the manufacturer's specifications for the hydraulic components. The specifications should include the recommended pressure and flow ratings for optimum performance and durability. 2. System requirements: Assess the specific requirements of the concrete pump system. Consider factors such as the size of the pump, the volume and distance of concrete being pumped, and the speed at which the concrete needs to be delivered. These factors will help determine the required pressure and flow rating for the hydraulic components. 3. Safety considerations: Ensure that the pressure and flow rating of the hydraulic components are within the safe operating limits of the concrete pump system. Exceeding these limits can lead to equipment failure, accidents, or damage to the components. 4. Compatibility: Verify that the hydraulic components are compatible with the rest of the system. The pressure and flow rating should match the capabilities and specifications of other components such as the pump, valves, and hoses to ensure proper functionality and performance. 5. Consultation with experts: If unsure about the appropriate pressure and flow rating for hydraulic components, consult with hydraulic system experts or the manufacturer's technical support team. They can provide guidance based on their expertise and experience with similar systems. It is important to note that the pressure and flow rating of hydraulic components may vary depending on the specific model, design, and intended application. Therefore, it is crucial to refer to the manufacturer's guidelines and recommendations to ensure accurate determination of the correct pressure and flow rating for hydraulic components in concrete pump spare parts.

- Q: How long do rubber pistons typically last in a concrete pump?

- The durability of rubber pistons in a concrete pump can differ based on various factors, including the rubber quality, frequency of use, concrete type, and maintenance practices. On average, rubber pistons in a concrete pump typically endure for approximately 500 to 1,500 hours of operation. Nevertheless, certain top-notch rubber pistons have been reported to last even longer when given appropriate care and maintenance. To prolong the lifespan of rubber pistons in a concrete pump, it is essential to regularly inspect, lubricate, and replace worn-out components. It is worth noting that these estimations serve as general guidelines, and the actual lifespan may vary in specific instances.

- Q: How do concrete pump spare parts contribute to the overall performance of the pump?

- Enhancing the overall performance of the pump, concrete pump spare parts play a crucial role. These spare parts are specifically designed to endure the harsh and demanding conditions of pumping concrete, guaranteeing the efficiency and longevity of the pump. An important factor in the pump's overall performance is the ability of concrete pump spare parts to enhance pumping capacity and efficiency. These spare parts, including pump cylinders, pistons, and valves, are designed to ensure a consistent and smooth flow of concrete without any interruptions. By maintaining a steady flow, these spare parts maximize the pump's capacity, enabling it to handle larger volumes of concrete in less time. Furthermore, concrete pump spare parts contribute to the pump's performance by improving its durability and reliability. These spare parts are made from high-quality materials like hardened steel and wear-resistant alloys, specifically chosen to withstand the abrasive nature of concrete. This ensures that the pump can operate continuously without experiencing premature wear or failure. Concrete pump spare parts also ensure the safety of the pump operators and the environment. For instance, wear plates and cutting rings prevent concrete leakage, reducing the risk of accidents and environmental contamination. Similarly, seals and gaskets provide a secure and tight connection between different components, preventing leaks or malfunctions. Moreover, concrete pump spare parts reduce downtime and maintenance costs. As these spare parts undergo wear and tear during operation, they are designed to be easily replaceable. This allows for quick and efficient repair or replacement of damaged parts, minimizing the pump's downtime. Additionally, using genuine and high-quality spare parts reduces the need for frequent repairs and maintenance, resulting in lower overall maintenance costs. In conclusion, concrete pump spare parts are vital components that significantly contribute to the pump's overall performance. They enhance its pumping capacity, durability, and reliability, ensuring a smooth and efficient operation. Furthermore, these spare parts promote safety, reduce downtime, and minimize maintenance costs, making them indispensable for the optimal performance of concrete pumps.

- Q: What is the role of a concrete pump hopper vibrator?

- The role of a concrete pump hopper vibrator is to ensure the smooth and efficient flow of concrete from the hopper into the pump. It helps to prevent clogging and blockages by vibrating the hopper, which loosens the concrete and allows it to flow freely into the pump.

Send your message to us

PUMPING CYLINDER(PM) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords