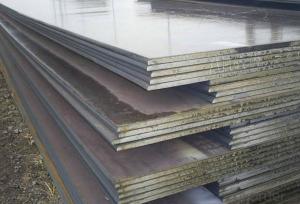

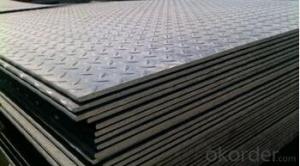

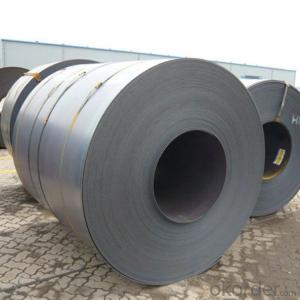

Prime quality Hot Rolled Steel Coils/Sheets Q235/SS400/ST 37-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

- Q: What is the maximum length of a steel sheet?

- The maximum length of a steel sheet can vary due to multiple factors like the steel mill's manufacturing capabilities, transportation limitations, and customer requirements. In general, steel sheets can range from a few feet to several hundred feet in length. Large-scale steel mills have the ability to produce exceptionally long sheets, often surpassing 100 feet or more. These extended lengths find their purpose in significant construction projects like bridges, industrial buildings, or shipbuilding. However, it is important to consider practical constraints when determining the sheet's maximum length, such as the size of transportation vehicles or handling equipment limitations. Hence, while manufacturing lengthy steel sheets is possible, practical considerations may limit their effective utilization in different applications.

- Q: Are steel sheets suitable for interior partition walls?

- Yes, steel sheets are suitable for interior partition walls. They are durable, fire-resistant, and provide exceptional strength and stability. Additionally, steel sheets can be easily customized and offer a sleek and modern aesthetic for interior spaces.

- Q: How do steel sheets perform in high-pressure applications?

- Steel sheets perform well in high-pressure applications due to their high strength and durability. They are able to withstand the force exerted by the pressure, maintaining their structural integrity. Additionally, steel sheets have good resistance to deformation and can effectively distribute the pressure, reducing the risk of failure.

- Q: Stainless steel plate how to cast mirror plate?

- Jacksonlea brand stainless steel polishing pasteThe supply of Jacksonlea brand stainless steel polishing paste, with the use of polishing wheel, can provide excellent gloss, providing the whole face of Gaoping. According to the customer's quality requirements, can provide rough, medium, fine specifications, with cloth, hemp wheel use.

- Q: Are steel sheets suitable for construction applications?

- Yes, steel sheets are highly suitable for construction applications. Steel is known for its strength, durability, and versatility, making it a popular choice in the construction industry. Steel sheets are commonly used in various applications, such as roofing, flooring, wall panels, structural frames, and cladding. They offer excellent load-bearing capacity, allowing for the construction of large and sturdy structures. Steel sheets are also fire-resistant, which enhances the safety of the building. Additionally, steel is resistant to pests, rot, and corrosion, ensuring a longer lifespan for the construction. Furthermore, steel sheets can be easily fabricated and customized to fit different construction needs, making them a cost-effective and efficient option. Overall, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and numerous other beneficial properties.

- Q: How is the quality of steel sheets determined?

- The quality of steel sheets is determined by several factors and tests. One of the primary factors is the chemical composition of the steel, which includes the presence and percentage of various elements such as carbon, manganese, silicon, and alloying elements like chromium, nickel, and molybdenum. The specific composition affects the steel's strength, durability, and resistance to corrosion. Another important aspect is the mechanical properties of the steel, which are assessed through tests such as tensile strength, yield strength, elongation, hardness, and impact resistance. These tests help determine the steel's ability to withstand applied forces and deformation without failure. Surface quality is also crucial in determining the quality of steel sheets. The surface should be free from defects like cracks, scratches, pits, or any other irregularities that could affect the performance or appearance of the steel. Furthermore, the thickness and uniformity of the steel sheets are crucial factors. Thickness is measured using methods like ultrasonic gauges or micrometers to ensure compliance with the required specifications. Any deviations from the specified thickness can affect the structural integrity and performance of the steel sheets. Additionally, the steel sheets undergo various tests to assess their weldability, formability, and machinability, which determine their suitability for specific applications. These tests help evaluate the steel's behavior during fabrication processes like welding, bending, or machining. Overall, the quality of steel sheets is determined by a comprehensive evaluation of their chemical composition, mechanical properties, surface quality, thickness, and other specific performance characteristics. These assessments ensure that the steel sheets meet the required standards and are suitable for the intended applications.

- Q: What are the different cutting methods for steel sheets?

- There are several cutting methods commonly used for steel sheets, including shearing, laser cutting, plasma cutting, waterjet cutting, and abrasive cutting. Each method has its own advantages and suitability depending on the thickness and type of steel, desired precision, speed, and cost considerations.

- Q: What are the different edge finishes available for steel sheets?

- Depending on the desired aesthetic and functional requirements, steel sheets offer various edge finishes. The most common options are as follows: 1. Mill Edge: Directly from the steel mill, this is the standard and unfinished edge. It is typically used in non-critical applications like industrial or structural use. 2. Trimmed Edge: Irregularities and burrs are removed by trimming or shearing the rough mill edge. This provides a cleaner and more uniform edge, making it suitable for applications where appearance matters. 3. Deburred Edge: Through a deburring process, sharp or jagged edges are eliminated, resulting in a smooth and rounded edge. This enhances safety, making it common in applications involving frequent handling or contact. 4. Beveled Edge: The edge is cut or ground at an angle, creating a sloping or chamfered edge. This improves both aesthetics and functionality, especially in architectural applications and jointing or welding. 5. Rolled Edge: By rolling or bending the steel sheet's edge, a rounded or folded edge is formed. Rolled edges provide a smooth and finished appearance, making them ideal for visible applications like decorative or furniture manufacturing. 6. Hemmed Edge: Folding the edge of the steel sheet over itself creates a double-layered and durable edge resistant to fraying or unraveling. Hemmed edges are commonly used in exposed areas that require added durability, such as roofing or sign manufacturing. These examples demonstrate the range of edge finishes available for steel sheets. Each finish offers unique characteristics and benefits, allowing for customization based on specific requirements and preferences.

- Q: Are the steel sheets suitable for solar panel mounting?

- Yes, steel sheets are suitable for solar panel mounting. They provide strong support and durability, making them an ideal choice for securely mounting solar panels on various surfaces.

- Q: Are steel sheets suitable for oil rig platforms?

- Oil rig platforms benefit greatly from the use of steel sheets. The reason for this lies in the exceptional strength and durability of steel, which makes it a popular choice in their construction. Given the harsh environmental conditions that oil rig platforms face, such as extreme temperatures, high winds, and corrosive saltwater, steel has proven itself capable of withstanding these challenges effectively. Steel sheets offer a solid and dependable base for oil rig platforms. They ensure that the platforms can bear the weight of the rig, equipment, and personnel without compromising stability or safety. The high strength of steel allows for the construction of large and intricate structures without sacrificing stability. Moreover, steel exhibits remarkable resistance to corrosion, making it an ideal material for offshore applications. Oil rig platforms are constantly exposed to saltwater, which can cause corrosion and weaken other materials. However, steel sheets can be treated with protective coatings to enhance their resistance to corrosion and extend their lifespan. In addition to its strength and corrosion resistance, steel is a versatile material that lends itself to easy shaping and fabrication. This versatility allows for efficient and cost-effective construction processes, reducing the time and resources required for installation and maintenance. In conclusion, steel sheets are a suitable choice for oil rig platforms due to their strength, durability, corrosion resistance, and versatility. They provide a reliable and robust foundation for offshore drilling operations, ensuring the safety and longevity of the platform in challenging environments.

Send your message to us

Prime quality Hot Rolled Steel Coils/Sheets Q235/SS400/ST 37-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords