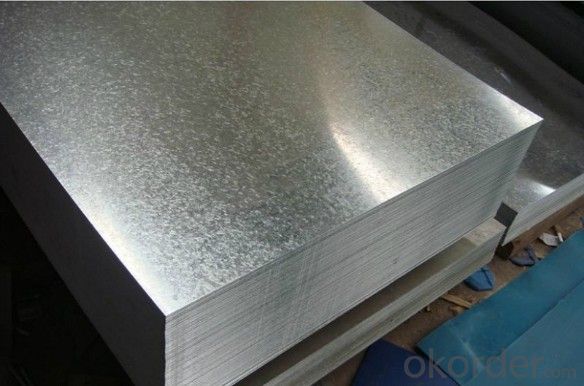

Prime Quality Hot Dipped Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil:

1. Thickness: 0.13mm-0.7mm

2. Width: 600mm-1250mm

3. Zinc Coating: 30-200g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry , chromated , non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

Chemical Composition | C | Si | Mn | P | S |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data | |

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Out-of-square | not exceed 1% Flatness |

Bow | 15mmmax |

Edge Wave | 9mmmax |

Centre Buckle | 8mmmax |

Bending At 180 Degree | No crack, purling and fraction |

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

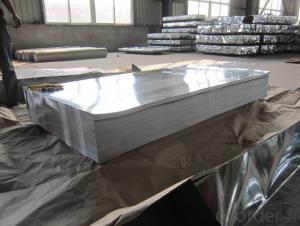

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips.

- Q: How are steel sheets inspected for defects?

- Steel sheets are inspected for defects using various techniques and methods to ensure their quality and reliability. One common method is visual inspection, where trained inspectors carefully examine the surface of the steel sheet for any visible defects such as cracks, scratches, dents, or surface irregularities. This is typically done under proper lighting conditions to enhance visibility. Another technique is magnetic particle inspection, which is used to detect surface or near-surface defects in ferromagnetic materials like steel. In this method, a magnetic field is applied to the steel sheet, and iron particles are then applied to the surface. If there are any defects, these particles will be attracted and form visible indications, allowing inspectors to identify the location and size of the defect. Ultrasonic inspection is another commonly used method that involves the use of high-frequency sound waves to detect internal defects in steel sheets. Ultrasonic waves are passed through the material, and any changes in the wave patterns caused by defects are detected by sensors. This non-destructive testing method can identify defects such as voids, cracks, or inclusions that may not be visible to the naked eye. Other techniques used for defect detection in steel sheets include eddy current testing, where electrical currents are induced in the material to detect surface defects, and X-ray inspection, which uses high-energy X-rays to reveal any internal flaws. Overall, a combination of visual inspection and non-destructive testing methods is employed to thoroughly inspect steel sheets for defects, ensuring that only high-quality sheets are used in various applications like construction, automotive, or manufacturing industries.

- Q: What is the minimum thickness of steel sheets?

- The minimum thickness of steel sheets can vary depending on the specific application and industry requirements. However, it generally ranges from around 0.4 millimeters to 6 millimeters.

- Q: What is the typical hardness range for steel sheets?

- The typical hardness range for steel sheets varies depending on the specific grade and type of steel being used. However, in general, steel sheets typically have a hardness range between 150 and 250 on the Vickers hardness scale (HV). This range provides a good balance between strength and formability, making steel sheets suitable for a wide range of applications. It is important to note that hardness can be further adjusted through various heat treatment processes to achieve specific desired properties.

- Q: Can steel sheets be used for roofing purposes?

- Yes, steel sheets can be used for roofing purposes. Steel roofing sheets are commonly used in commercial and industrial buildings, as well as residential homes. They are known for their durability, longevity, and resistance to harsh weather conditions such as rain, snow, and wind. Steel sheets are available in various profiles and finishes, allowing for customization to suit different architectural styles and design preferences. Additionally, steel roofing is lightweight, fire-resistant, and often made from recycled materials, making it an environmentally friendly roofing option. Overall, steel sheets are a popular choice for roofing due to their strength, versatility, and aesthetic appeal.

- Q: Can steel sheets be used for walkways or platforms?

- Yes, steel sheets can be used for walkways or platforms. Steel is a durable and strong material, making it suitable for supporting heavy loads and providing a safe surface for walking. It is commonly used in industrial settings, construction sites, and other applications where a sturdy and reliable platform is needed.

- Q: What is the difference between a smooth and patterned steel sheet?

- A plain and uniform surface characterizes a smooth steel sheet, devoid of any visible patterns or textures. It boasts a consistent and sleek appearance, rendering it ideal for situations that call for a clean and contemporary look. In contrast, a patterned steel sheet showcases a myriad of designs or textures that are either embossed or etched onto its surface. These patterns can range from simple geometric shapes to intricate motifs. People often opt for patterned steel sheets due to their decorative appeal, as they have the ability to enhance the visual interest of a space. They are commonly employed in architectural elements, such as wall panels or ceiling tiles, to create a distinct and artistic effect. When it comes to functionality, smooth steel sheets might offer slightly superior corrosion resistance due to their smoother surface. This makes them well-suited for applications that require protection against rust, such as in outdoor or marine environments. On the other hand, patterned steel sheets may exhibit reduced corrosion resistance due to the variation in surface texture, potentially providing less safeguarding against rust. In conclusion, the decision between a smooth and patterned steel sheet hinges on the desired aesthetic, functional requirements, and the intended application.

- Q: What are the different strength properties of steel sheets?

- The different strength properties of steel sheets include yield strength, tensile strength, and elongation. Yield strength refers to the maximum amount of stress a material can withstand without permanent deformation. Tensile strength is the maximum amount of stress a material can handle before breaking. Elongation is the measure of how much a material can stretch or deform before breaking. These strength properties are important factors to consider when determining the suitability of steel sheets for various applications.

- Q: How do steel sheets compare to fiberglass sheets?

- Steel sheets and fiberglass sheets have various differences in terms of strength, weight, and durability. Steel sheets are generally stronger and more rigid than fiberglass sheets, making them suitable for applications where high strength is required. They also have better resistance to impact and fire, making them safer in certain environments. However, steel sheets are heavier and more prone to corrosion compared to fiberglass sheets. Fiberglass sheets are lighter, have better resistance to chemicals and weathering, and are non-conductive, making them ideal for electrical applications. Additionally, fiberglass sheets are easier to handle and install due to their flexibility. Overall, the choice between steel and fiberglass sheets depends on the specific application requirements and priorities.

- Q: Are the steel sheets corrosion-resistant?

- Yes, steel sheets can be corrosion-resistant depending on the type of steel used and the protective coating applied. Stainless steel sheets, for example, are known for their excellent corrosion resistance due to the presence of chromium that forms a passive protective layer on the surface. Additionally, galvanized steel sheets are coated with a layer of zinc, which acts as a sacrificial barrier to protect the underlying steel from corrosion. Other types of steel sheets can also be made corrosion-resistant through the application of coatings or treatments such as painting, powder coating, or plating. Therefore, it is important to consider the specific type of steel and any additional protective measures taken to determine the corrosion resistance of steel sheets.

- Q: Can steel sheets be used for storage racks?

- Indeed, storage racks can indeed be made using steel sheets. Renowned for their robustness and strength, steel sheets are an optimal choice when it comes to constructing storage racks. They possess the ability to bear substantial weights and offer steadfastness to the entire storage system. Furthermore, steel sheets can be effortlessly fabricated and tailored to suit the precise specifications of the storage area. Moreover, steel exhibits resistance against corrosion, guaranteeing the durability of the storage racks and rendering them suitable for employment indoors as well as outdoors.

Send your message to us

Prime Quality Hot Dipped Galvanized Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords