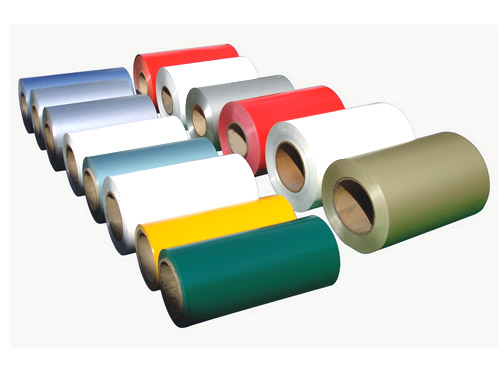

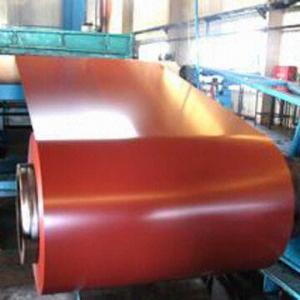

Prime Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

PPGI – White – Z100/Z120

709mm x 0.40mm x Coil

745mm x 0.35mm x Coil

745mm x 0.40mm x Coil

855mm x 0.50mm x Coil

1000mm x 0.40mm x Coil

1250mm x 0.50mm c Coil

PPGI – Dark Grey – Z100/Z120

1250mm x 0.50mm x Coil

shine surfaceVALIDITY: 3 WORKING DAYSPAYMENT: T/T WITH 30% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LISTSHIPMENT: 50 DAYS FOR CARGO READINESS AND 15 DAYS FOR CATCHING THE RIGHT VESSEL

- Q: What is the tensile strength of steel coils?

- The tensile strength of steel coils can vary depending on the specific grade of steel used, but it typically ranges from 300 to 2,000 megapascals (MPa).

- Q: What are the common methods of packaging steel coils for transportation?

- There are several common methods of packaging steel coils for transportation. One widely used method is to use steel strapping or bands to secure the coils together. This method involves tightly wrapping the coils with steel bands and securing them with metal buckles or seals. The strapping helps to keep the coils in place and prevents them from shifting or rolling during transportation. Another common method is to use wooden pallets or skids to stack and transport the steel coils. The coils are placed on the pallets and secured with steel strapping or bands. This method provides stability and allows for easy handling and loading onto trucks or other transportation vehicles. Some steel coils are also packaged in wooden crates or boxes. These crates are typically made of strong and durable wood and are designed to protect the coils from external impacts or damage during transportation. The crates are often reinforced with steel bands or strapping to provide additional strength and stability. In addition to these methods, some steel coils are packaged in specialized containers or units. These containers are specifically designed to hold and secure steel coils for transportation. They often have built-in mechanisms or features that make loading and unloading the coils easier and safer. It is important to note that the specific method of packaging steel coils for transportation may vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations in place.

- Q: I am wondering if i can use my western guitar as a kind of steel-guitar, read something about it on Wikipedia.

- If you decide to get a true pedal steel, plan on spending some big money. Look on eBay for a Carter Starter. It will be the best guitar to start on...and not outgrow too fast.

- Q: What are the different coil coatings available for steel coils?

- There are several different coil coatings available for steel coils, each offering unique benefits and characteristics. Here are some of the most common coil coatings used in the industry: 1. Polyester: Polyester coil coatings are widely used due to their excellent durability and resistance to fade, scratch, and corrosion. They provide good UV resistance and are available in a wide range of colors. 2. Polyvinylidene fluoride (PVDF): PVDF coatings are known for their exceptional resistance to weathering and UV radiation. They offer excellent color retention, gloss retention, and overall durability, making them suitable for outdoor applications. 3. Polyurethane: Polyurethane coil coatings provide a high level of abrasion resistance and flexibility. They offer excellent chemical resistance and are often used in industries such as automotive and appliances. 4. Silicone modified polyester (SMP): SMP coatings offer good resistance to fading, chalking, and cracking. They provide excellent weather resistance and are commonly used in architectural applications. 5. Epoxy: Epoxy coil coatings are known for their excellent adhesion and chemical resistance. They are often used in demanding environments such as automotive parts and appliances. 6. Plastisol: Plastisol coatings are PVC-based and provide a thick, flexible film on the surface of the steel coil. They offer excellent corrosion resistance and are commonly used in the construction industry. These are just a few examples of the different coil coatings available for steel coils. The choice of coating depends on factors such as the intended application, environmental conditions, desired appearance, and required performance characteristics. Consulting with a coil coating expert can help determine the most suitable coating for a specific project.

- Q: How are steel coils used in the production of bridges?

- Steel coils are used in the production of bridges as they provide a reliable and strong structural material. These coils are shaped and formed into various components, such as beams and girders, which are then assembled to create the bridge's framework. The steel coils' durability and high tensile strength make them ideal for supporting heavy loads and withstanding the forces experienced by bridges.

- Q: I am thinking of buying a stainless steel necklace, but I need to know if it will discolor. My brothers ring turned brown, but he forgot what kind of metal it was. Also answer if I can wear it in the shower because I wear my other necklace in it.

- I would say don't wear it in the shower because it will tarnish and it could rust.

- Q: Can steel coils be coated with aluminum?

- Yes, steel coils can be coated with aluminum. The process is known as the hot-dip method, where the steel is first cleaned and then dipped into a bath of molten aluminum. This results in a protective layer of aluminum coating on the steel surface, enhancing its corrosion resistance and providing aesthetic appeal.

- Q: Can steel coils be coated with chemical-resistant materials?

- Yes, steel coils can be coated with chemical-resistant materials. The use of chemical-resistant coatings helps protect the steel coils from corrosion and damage caused by exposure to various chemicals, acids, or solvents. These coatings create a barrier that prevents the chemicals from reaching the steel surface and ensure the durability and longevity of the coils in harsh chemical environments.

- Q: How are steel coils inspected for hardness using hardness testers?

- Steel coils are inspected for hardness using hardness testers in order to determine the strength and durability of the steel. Hardness testers are devices specifically designed to measure the resistance of a material to indentation or penetration. In the case of steel coils, the hardness testers typically used are either Rockwell or Brinell testers. Both methods involve applying a specific force to the surface of the steel coil and measuring the depth of indentation or the size of the impression made. For Rockwell testing, a steel ball or a diamond cone is pressed into the surface of the coil with a predetermined force. The depth of penetration is measured and compared to a standardized scale to determine the hardness value. Different scales are used depending on the size and type of indenter used. Brinell testing, on the other hand, involves using a spherical indenter made of tungsten carbide or hardened steel, which is pressed into the surface of the steel coil with a known force. The size of the resulting indentation is measured and compared to a standardized table to determine the hardness value. Both methods provide a quantitative measure of the steel coil's hardness, which indicates its ability to resist deformation, wear, and cracking. The results obtained from hardness testing can then be used to ensure the steel meets specific quality standards or customer requirements. It is important to note that the inspection process may involve sampling, where representative sections of the steel coil are tested, or it may involve testing the entire coil, depending on the specific requirements of the inspection. Additionally, proper calibration and maintenance of the hardness testers are crucial to ensure accurate and reliable results.

- Q: How are steel coils manufactured?

- Steel coils are manufactured through a multi-step process that involves heating and shaping steel slabs, followed by passing them through a series of rolling mills to reduce their thickness and increase their length. The coils are then cooled, inspected for quality, and finally, wrapped and ready for shipping.

Send your message to us

Prime Prepainted Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords