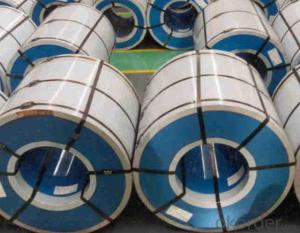

prepainted steel coil from steel manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | Q235,SS400,Q215,Q195,SPCC | Thickness: | 0.14MM TO 0.8MM |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | CNBM | Model Number: | COIL |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | NEGOTIATED | Special Use: | High-strength Steel Plate | Width: | 10MM TO 1500MM |

| Length: | 10MM TO 1500MM |

Packaging & Delivery

| Packaging Detail: | COIL, wood or steel pallets wit plastic film, professional exporting seaworthy package, load by container or breakbulk vessel or according to customers' requirement . |

| Delivery Detail: | 1 MONTH |

Specifications

PPGI/Prepainted steel coil

Thickness: 0.14-0.80mm

Width:600-1250mm ,Znic:50-180g/M2

Colour:20-25um

Certificate:ISO9001:2000

Specifications

PPGI / prepainted steel coil

high quality and good price

PPGI / prepainted steel coil

1.Production details:

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

Manufacturer | Thickness | Width | Length of plate | Inner diameter of coil |

CNBM | 0.2-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment primarily for their strength, durability, and corrosion resistance. These coils are utilized to manufacture various components such as pipes, valves, fittings, and storage tanks that are required in the exploration, drilling, and transportation of oil and gas.

- Q: How do steel coils contribute to the energy storage industry?

- The energy storage industry benefits greatly from the use of steel coils in multiple ways. Initially, steel coils are instrumental in the fabrication of energy storage systems like batteries. Through their steel casing, batteries are provided with both structural support and protection for the battery cells, ensuring their safety and longevity. If not for steel coils, batteries would be more susceptible to damage and unable to function efficiently. Furthermore, the construction of flywheels, an alternative form of energy storage technology, heavily relies on steel coils. Flywheels store energy by spinning a rotor at high speeds and releasing the stored energy when necessary. Steel coils are employed to create the rotor, which necessitates strength, durability, and the ability to withstand substantial rotational forces. Additionally, the magnetic properties of steel contribute to the enhancement of energy transfer efficiency within the flywheel system. Moreover, compressed air energy storage (CAES) systems also utilize steel coils in their production. CAES systems store energy by compressing air and releasing it to generate electricity upon demand. Steel coils are crucial in constructing the air storage chamber, guaranteeing its integrity and preventing any leakage or damage. The robust nature of steel coils makes them ideal for enduring the high pressures associated with the compression process. To summarize, the energy storage industry greatly benefits from the utilization of steel coils. They provide essential structural support, durability, and protection to various energy storage technologies, whether it be batteries, flywheels, or CAES systems. By contributing to the efficient and secure storage of energy, steel coils facilitate the advancement and adoption of sustainable energy solutions.

- Q: If I wear a pair of thick wool socks, is walking around in the snow with steel-toed boots going to be a problem? I'm wondering if the steel will make my toes too cold.

- should be ok and not cold if you go by what is written in the posting you quoted however if you are thinking of buying them just for the snow i would consider something else much cheaper. however if you already have them then not a problem, i suggest you give it a test run.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Steel manufacturers have the capability to produce coils in various sizes and thicknesses to meet the specific requirements of customers. This allows for flexibility in applications and ensures that the steel coils can be tailored to suit different industries and projects.

- Q: What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are large steel companies such as ArcelorMittal, Nippon Steel Corporation, POSCO, Baosteel Group, and Tata Steel. These companies have a significant global presence and dominate the market due to their extensive production capabilities, advanced technologies, and strong distribution networks. Additionally, there are several other regional and local players that cater to specific markets and niche segments within the industry.

- Q: How are steel coils inspected for color consistency?

- Steel coils are inspected for color consistency through visual inspection by trained personnel. They compare the color of the coils against a color standard to ensure uniformity and consistency across the entire batch.

- Q: Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- Weigh it. I'm not an expert on coins, but if the 1944 was 100% steel, I would expect it to weigh something different then modern pennies. Another test would be to measure the resistance with a micro-ohm meter. This is a specialized device that can measure resistance to a millionth of an ohm. Steel should have a different resistance than the metals used on other pennies. Here are some comments from wikipedia: In 1943, at the peak of World War II, cents of zinc-coated steel were made for a short time due to war demands for copper. A few (the U.S. Mint reports forty) copper cents from 1943 were produced from the 1942 planchets remaining in the bins. Similarly, some 1944 steel cents have been reported. Following 1943, salvaged ammunition shells made their way into the minting process, and it was not uncommon to see coins featuring streaks of brass or having a considerably darker finish than other issues.

- Q: Can steel coils be cut?

- Yes, steel coils can be cut.

- Q: What are the major challenges faced by steel coil manufacturers?

- Steel coil manufacturers encounter various obstacles across different areas. These challenges can be grouped into several key categories. Firstly, one of the primary hurdles is the fluctuating prices of raw materials, such as iron ore and coal, which are vital for steel production. To maintain profitability, manufacturers must constantly monitor and adjust their pricing strategies to mitigate the impact of these fluctuations. Secondly, intense competition arises from both domestic and international players in the steel coil manufacturing industry. Globalization has increased the availability of steel coils from various regions. Therefore, manufacturers must differentiate themselves through quality, pricing, and customer service to remain competitive. Thirdly, the steel industry is continuously evolving and adopting new technologies. Manufacturers need to invest in modern equipment and machinery to improve efficiency, reduce costs, and meet stringent quality standards. However, keeping up with technological advancements can be challenging, particularly for smaller or financially unstable manufacturers. Fourthly, steel production is a resource-intensive process that significantly impacts the environment. Governments worldwide have imposed stricter regulations on emissions, waste disposal, and energy consumption. Compliance with these regulations requires substantial investments in pollution control technologies and sustainable practices. Fifthly, the steel industry requires a skilled workforce with expertise in areas such as metallurgy, engineering, and operations. However, attracting and retaining skilled employees is challenging due to a shortage of qualified personnel. Manufacturers must invest in training and development programs to ensure a competent workforce and maintain operational excellence. Sixthly, steel coil manufacturers are highly sensitive to economic fluctuations. During economic downturns, demand for steel products decreases, leading to excess capacity and lower profit margins. Conversely, during economic booms, manufacturers may struggle to meet increased demand and ensure timely delivery. Lastly, transportation and logistics present a significant challenge for steel coil manufacturers due to the bulky and heavy nature of their products. Optimizing supply chain management, coordinating with freight partners, and ensuring timely delivery across various geographies can be complex and costly. In conclusion, steel coil manufacturers face challenges in several areas, including raw material costs, global competition, technological advancements, environmental regulations, skilled workforce requirements, economic volatility, and transportation logistics. Overcoming these challenges necessitates proactive strategies, continuous improvement, and a focus on innovation to remain competitive in the industry.

- Q: How are steel coils used in the production of structural steel?

- Steel coils are widely used in the production of structural steel due to their versatility and efficiency. These coils, which are made by rolling steel into a cylindrical shape, serve as the raw material for various structural steel products. One of the primary uses of steel coils in the production of structural steel is in the manufacturing of beams and columns. These coils are processed in steel mills, where they undergo cutting, shaping, and bending to form the desired profiles. Beams and columns are essential components of any building or infrastructure project as they provide support and stability. Steel coils are also used in the fabrication of steel plates, which are widely used in the construction industry. These plates are used for flooring, cladding, and roofing purposes, adding strength and durability to structures. By using steel coils as the starting material, manufacturers can produce steel plates of various thicknesses and sizes according to project requirements. Furthermore, steel coils are an integral part of the production process for pipes and tubes. These coils are formed into a cylindrical shape and then welded or seamless to create pipes and tubes of different diameters. Steel pipes and tubes are vital for various applications, including water and gas transportation, structural frameworks, and industrial systems. In addition to these applications, steel coils are also used in the production of other structural steel products such as angles, channels, and hollow sections. These products are widely used in construction projects, providing structural support, reinforcement, and aesthetic appeal. Overall, steel coils play a crucial role in the production of structural steel by serving as the raw material for various products. Their versatility, ease of processing, and strength make them an ideal choice for manufacturers, ensuring the production of high-quality and reliable structural steel components.

Send your message to us

prepainted steel coil from steel manufacture

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords