Prepainted Steel Corrugated Plate / Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Characteristic of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

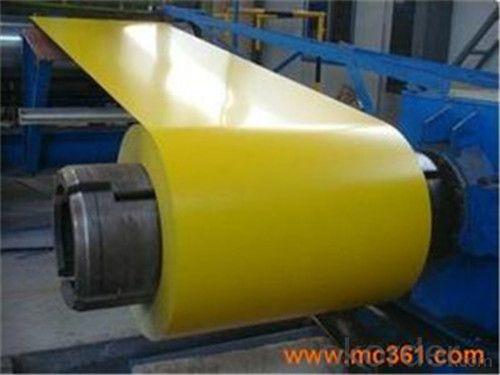

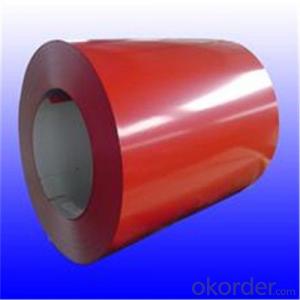

Images of Prepainted Galvanized Steel:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What is the width range of steel coils?

- The width range of steel coils can vary depending on the specific type and purpose of the coil, but it typically falls within the range of 600 mm (23.6 inches) to 2,200 mm (86.6 inches).

- Q: i have a sword and some knives that have this grade steel. so is it a high grade or low grade? and how can i tell the differance between a high grade and a low grade?

- I own a claymore made of 440 stainless steel, I cut a small tree in half. I was surprised, I mean I had always heard it broke very easily, but tell that to the tree. In other words it is a strong metal, but I don't sugest you tempt fate and try to break it because you will. As far as high grade the higher the grade the better the blade looks. If your looking for something to swing around, listen up Damascus is a good steel and Superalloys are probably the best. Take it from me, i'm an expert in using a sword and you'll only get hurt. Most of the time when you swing a sword you wound yourself and don't know it. When you swing the hilt of the sword also presents a problem, it can wound you too. Infact if you can't live with being cut up all the time don't pick up a sword. I cut my hands all the time and i'm a professional so you would probably kill yourself trying. Of course I do use heavy swords, but you can still hurt yourself with a light sword. So don't attempt anything stupid for your sake.

- Q: How much do steel coils weigh?

- The weight of steel coils is subject to variation, which is determined by multiple factors including coil thickness, width, length, and the particular type of steel employed. In general, steel coils can range in weight from a few hundred pounds to several tons. It should be emphasized that the measurement of steel coils typically revolves around their weight per unit area, referred to as the "basis weight" or "coil weight".

- Q: How are steel coils processed for different finishes?

- Steel coils can be processed for different finishes through various methods. One common process is called coil coating, where the steel coil is cleaned, primed, coated, and cured to achieve a desired finish. This process includes removing any contaminants from the surface of the coil, applying a primer to enhance adhesion, and then coating it with a specific paint or coating material. The coated coil is then cured at high temperatures to ensure proper adhesion and durability. Another method for processing steel coils is through galvanization. In this process, the steel coil is coated with a layer of zinc to protect it from corrosion. This can be done through hot-dip galvanization, where the coil is immersed in a bath of molten zinc, or through electro-galvanization, where a thin layer of zinc is electroplated onto the coil. The galvanized finish provides excellent corrosion resistance and can be further processed to achieve different aesthetic finishes. Additionally, steel coils can be processed for different finishes through various surface treatments. This may involve processes such as pickling, where the coil is treated with an acid solution to remove scale and impurities, or mechanical treatments like brushing or grinding to achieve a desired texture. These surface treatments can be followed by applying a protective coating or paint to enhance the appearance and durability of the coil. Overall, the process of achieving different finishes on steel coils involves a combination of cleaning, coating, curing, and surface treatments. The choice of specific methods depends on the desired finish and the intended application of the steel coil.

- Q: What is the accuracy of steel tape inspection?

- The precision is the minimum scale of this measuring tool. The minimum scale of the steel tape measure is millimeters, and the data below is the reading data,

- Q: What are the different types of steel coil slitting processes?

- There are several types of steel coil slitting processes, including rotary slitting, loop slitting, and pull-through slitting.

- Q: I just got my Daewoo K2 in 5.56 and i know they are tough and reliable but how well will it fair with steel rounds. I know shooting brass is better for any gun but what kind of extra wear and tear would i be looking at with shooting steel. Also what about reloading steel. Is it recomended. I would not even be asking this but steel is far cheaper than brass ammo, and i need to save some money.

- You can't reload steel cases. I don't really know, but you just can't. If a mild steel case is harder than the chamber and bolt of your firearm, you should have got a better firearm.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils lies in the manufacturing process. Hot rolled steel coils are produced by heating the steel to high temperatures and then rolling it while it is still hot. This process results in a rougher surface and less precise dimensions, but it makes the steel more malleable and easier to shape. On the other hand, cold rolled steel coils are manufactured by cooling the hot rolled coils and passing them through a series of rollers at room temperature. This process produces a smoother surface and tighter tolerances, making it suitable for applications that require precise dimensions and a higher quality finish.

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless can oxidize over time but it doesn't look much like regular rust. Depending on the exact composition of the stainless alloy in question and what other materials are in contact with it, that's more or less of an issue. In constant contact with skin oils and gentle polishing from contact with skin and clothing, watches rarely rust regardless of what they're made of, I think you have nothing to worry about. Note: for future reference, bleach is absolute hell on stainless. It's bad enough on steel, worse on stainless. Especially because you have this idea that stainless is more or less impervious, when in reality it just isn't.

- Q: Can steel coils be used in marine environments?

- Yes, steel coils can be used in marine environments. However, it is essential to ensure that the steel coils are properly protected against corrosion, as the saltwater and high humidity in marine environments can accelerate the process of rusting. Various coatings and treatments can be applied to steel coils to enhance their resistance to corrosion and make them suitable for use in marine applications.

Send your message to us

Prepainted Steel Corrugated Plate / Sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords