Cold Rolled Steel Coils Grade 304 NO.2B made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cold Rolled Steel Coils Grade 304 NO.2B made in China

Products Description

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

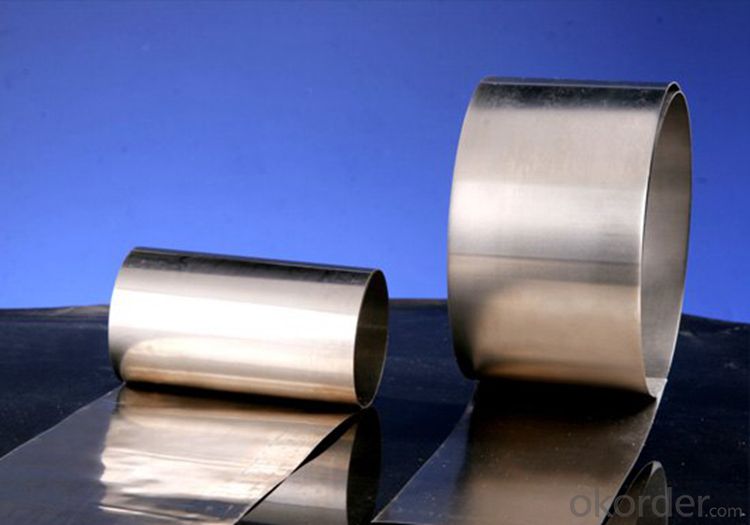

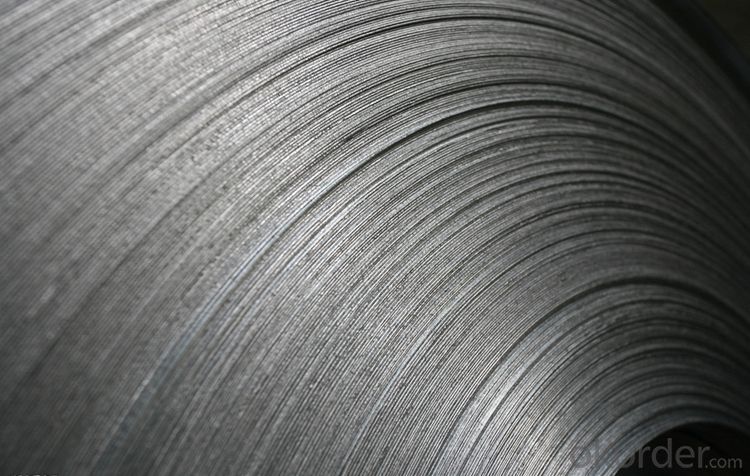

Detail picture of Products:

Application:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Can stainless steel sheets be used for soundproofing?

- Yes, stainless steel sheets can be used for soundproofing to a certain extent. While stainless steel itself is not a soundproofing material, it can be used as part of a soundproofing system. Stainless steel sheets can be installed as a barrier to block or reflect sound waves, reducing the amount of noise that passes through. However, for effective soundproofing, additional materials such as acoustic insulation and mass-loaded vinyl are typically used in conjunction with stainless steel sheets.

- Q:How do I choose the appropriate gauge for stainless steel sheets?

- When choosing the appropriate gauge for stainless steel sheets, there are a few factors to consider. First, you need to determine the intended use of the sheets. Thicker gauges offer more strength and durability, making them suitable for heavy-duty applications like industrial machinery or construction. If you require flexibility or a lighter weight, thinner gauges may be more appropriate for applications such as automotive or decorative purposes. Additionally, consider the environmental conditions the sheets will be exposed to, as this may affect the required gauge for corrosion resistance. Ultimately, consulting with a stainless steel supplier or industry expert can help you select the most suitable gauge based on your specific needs.

- Q:Are stainless steel sheets resistant to fire?

- Yes, stainless steel sheets are highly resistant to fire. Due to their high melting point and excellent heat resistance, stainless steel sheets do not easily ignite or contribute to the spread of fire, making them ideal for applications where fire safety is crucial.

- Q:What are the benefits of using perforated stainless steel sheets in ventilation systems?

- Perforated stainless steel sheets offer several benefits in ventilation systems. Firstly, they allow for efficient airflow by allowing air to pass through the small holes, ensuring proper ventilation and preventing any blockages. Secondly, the stainless steel material is highly durable and resistant to corrosion, ensuring long-term performance in various environments. Additionally, these sheets provide a sleek and aesthetically pleasing appearance, making them suitable for both industrial and commercial applications. Lastly, the perforations can be customized to meet specific airflow requirements, offering flexibility in design and functionality.

- Q:What is the water absorption rate of stainless steel sheets?

- The water absorption rate of stainless steel sheets is extremely low, as stainless steel is a non-porous material that does not readily absorb water.

- Q:What are the common methods of cutting stainless steel sheets?

- Cutting stainless steel sheets can be done using various methods, each with its own advantages and limitations. Let's take a look at a few commonly employed techniques: 1. Shearing: When using shearing, a machine with two blades is utilized to effortlessly slice through the stainless steel sheet. This technique is ideal for thinner sheets and delivers clean, straight cuts. However, there is a possibility of a slight burr on the cut edge. 2. Plasma cutting: Plasma cutting is a versatile approach that harnesses a high-temperature plasma arc to melt and remove the metal. This method is effective for cutting stainless steel sheets of different thicknesses and shapes. It offers speedy and precise cuts, accommodating both straight and curved lines. 3. Laser cutting: Laser cutting relies on a focused laser beam to effectively slice through stainless steel sheets. It is known for its high level of accuracy, generating smooth and precise cuts with minimal distortion. Laser cutting is suitable for thin and thick sheets but may be slower than other methods when dealing with thicker materials. 4. Waterjet cutting: Waterjet cutting employs a high-pressure stream of water mixed with abrasive particles to carve through stainless steel. This technique is renowned for its precision and ability to handle varying thicknesses and shapes. Waterjet cutting produces clean edges and avoids heat-affected zones. However, it may be slower and more costly compared to other methods. 5. Sawing: Sawing is a traditional method that employs a saw blade to cut through stainless steel sheets. It is most suitable for thicker sheets and can handle both straight and curved cuts. Sawing yields relatively clean cuts, although it may result in more material waste compared to other techniques. These are just a few examples of the common methods employed to cut stainless steel sheets. The choice of method depends on factors such as sheet thickness, desired cut quality, shape complexity, and budget. It is crucial to consider the specific requirements of the project and seek professional advice to determine the most suitable cutting method.

- Q:Are stainless steel sheets suitable for elevator flooring?

- Yes, stainless steel sheets are suitable for elevator flooring. They are durable, resistant to corrosion, easy to clean, and provide a sleek and modern look that complements the interior design of elevators.

- Q:How do you cut stainless steel sheets?

- Cutting stainless steel sheets can be done using different methods, depending on the thickness of the sheet and the desired precision of the cut. Here are a few common techniques: 1. Manual cutting: For thinner stainless steel sheets (up to around 16 gauge), you can use a handheld shear or tin snips. These tools allow you to cut straight lines or curves by applying pressure and cutting through the sheet. However, this method may not be suitable for thicker sheets as it can be labor-intensive and produce rough edges. 2. Power shears: For thicker stainless steel sheets, power shears or electric nibblers are more effective. These tools use a sharp cutting blade or punch to make straight or curved cuts. They provide more precision and require less effort compared to manual cutting methods. 3. Circular saw: A circular saw with a carbide-tipped blade designed for cutting metal can also be used to cut stainless steel sheets. This method is suitable for thicker sheets and allows for straight cuts. However, it may produce more noise, sparks, and heat, so proper safety measures such as wearing protective goggles and gloves should be taken. 4. Plasma cutting: For industrial or heavy-duty applications, plasma cutting is commonly used. This method involves using a high-temperature plasma jet to melt through the stainless steel sheet, creating a precise and clean cut. Plasma cutting machines are expensive and require specialized training to operate. Regardless of the method, it is important to take safety precautions when cutting stainless steel sheets. Always wear protective gear, such as safety glasses, gloves, and a dust mask, to protect yourself from metal shards, sparks, and dust. Additionally, ensure that the sheet is securely clamped or supported to prevent it from moving during the cutting process.

- Q:Stainless steel wire drawing without fingerprints, what principle?

- Let's say the principle: the material surface is easy to leave the fingerprint because the material has the characteristics of specular reflection on the light. The material is smooth enough, and the light is not diffusely reflective on the material, mainly specular. Landlord with your finger press the glass mirror will know

- Q:What does stainless steel sheet S2 stand for?

- Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold Rolled Steel Coils Grade 304 NO.2B made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords