Prepainted Steel Coil Without Anti-Dumping

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

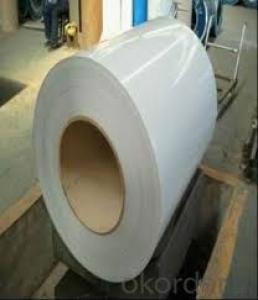

Description of Prepainted steel coils:

1) Standard: JIS G3312 CGCC & CGLCC, equivalent to ASTM A755M, EN10169

2) Grade: CGCC and CGLCC

3) Hardness of material: Both soft and full hard are available

4) Surface finish: With or without protect film covered

5) Thickness range: 0.14-1.20mm

6) Width range and General width: Width range 600-1250mm, general width: 914mm, 1000mm, 1220mm and 1250mm.

7) Shape: Both sheet and coil are available

8) Zinc coating: 60-275G/M2, both sides

9) Paint thickness: Top 5 um + (10-20) um modified polyester, any RAL color code. We use Beckers paint for producing.

10) Paint thickness: Reverse 5-10 um Epoxy

11) Coil weight: 4-6 tons, also can be upon customer's requirements

12) Max loading in one 20ft container: 25 tons generally

13) MOQ: 25 tons for each thickness or color;

14) Actual shipped quantity: More or less 5%;

15) Delivery time: 2 weeks or one month generally.

16) Applications: Widely used for roof tiles, outer walls, ovens, explosive-proof steel, electrically controlled cabinets, and industrial freezers in the residential and industrial buildings.

| Standard | JIS G3312 CGCC ASTM A755M EN10169 |

| Valid thickness | 0.20~1.20mm |

| Coil width | 600~1250mm |

| Coil ID | 508mm & 610mm |

| Coil weight | 3~5 tons |

| Zinc coating | 80~275 g/m2 |

| Thickness of top paint | 15~25 microns |

| Thickness of reverse paint | 5~7 microns |

| Color | any RAL code |

| Package | vertical, eye to sky & horizontal |

| MOQ | 25 tons |

- Q: What is the (balanced) chemical equation for steel?

- I hate to differ but I must. Steel is a mixture of iron and carbon but the carbon content ranges from a small fraction of a percent to no more than 2%. Stainless steel is an alloy of Iron and up to 15% or so of other metals but since there are several types and many varieties in each type it's hardly worth getting into. A good common hardenable high-carbon spring steel is AISI 1095. In this code the 95 refers to 0.95% carbon. When the carbon level goes up to 1.5% to 2% the steel is very brittle and black with the highest carbon steel being pretty much pig-iron.

- Q: I am going to be working as a mechanic at my school and I just wanted to know if I should get the steel toe boots or regular. I heard that steel toe boots can be dangerous and uncomfortable. The mechanics recommended getting steel toe to be safe but i'm not sure.

- If I was you, I would get steel toe boots, because I got soft toe boots and at the toe part, it dented in, because I used them for riding dirtbikes, I wish I would of got steel toe boots, u should get steel toe because later on you might wish u would of got them:) hope this help

- Q: What is the size range of steel coils?

- The size range of steel coils can vary depending on the specific requirements and applications, but generally, they can range from a few inches to several feet in width and from a few thousand pounds to several tons in weight.

- Q: Are steel or graphite clubs better?

- I use steel shaft golf clubs (mens so called clubs) I find the garphite shaft that is typically used for womens clubs is too light and I have a messy swing Callaway Big Bertha is GREAT .... very forgiving club and the oversized clubhead is great for beginners up to advanced. *****FOR MEN - STEEL******* no graphite (just the woods have graphite shafts but the irons are steel

- Q: What are the dimensions of steel coils used in the furniture industry?

- The furniture industry utilizes steel coils of varying dimensions, which are determined by the specific application and requirements of the furniture manufacturer. Generally, these steel coils possess a thickness ranging from 0.20mm to 3.00mm and a width spanning from 600mm to 2000mm. The length of the coils may fluctuate, but it is typically within the range of 1000mm to 3000mm. These dimensions offer the necessary flexibility to shape and mold the steel coils into diverse furniture components like frames, springs, and structural supports.

- Q: How are steel coils used in the production of steel containers?

- Steel containers rely heavily on steel coils as a vital component in their production. These coils, made from flat-rolled steel, serve as the foundation for the container's main body. To start the process, the steel coils are unwound and fed into a rolling mill. Here, they undergo a sequence of procedures to shape and mold the steel. One of these steps involves heating the coils to a specific temperature, making them more malleable and easier to manipulate. Subsequently, the hot coils pass through a series of rollers that gradually reduce their thickness and elongate them to the desired size. This entire procedure is referred to as hot rolling. Once the steel coils have been rolled to the necessary thickness, they are then cooled and transformed into sheets. These sheets are further treated to eliminate any imperfections or irregularities, guaranteeing a smooth and even surface. This is accomplished through processes like pickling, where acid is used to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and refined, they are molded into the shape of the container. This typically involves a technique known as stamping, in which hydraulic presses are used to press the steel sheets into a mold. The mold determines the container's shape and size, and the steel sheets are pressed against it with great force, resulting in the desired container shape. Once the containers have been formed, they undergo several finishing processes, including welding, painting, and coating. These processes are carried out to enhance the containers' durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers meet the necessary standards and are of high quality for their intended use. In conclusion, steel coils are of paramount importance in the manufacturing of steel containers, as they provide the raw material needed for their production. Through a series of steps, the steel coils are shaped, cut, and formed into sheets, which are then further processed and molded into the desired container shape. The outcome is a robust and dependable steel container suitable for various applications across industries.

- Q: My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- Fire doesn't burn steel, fire is the catalyst for steel to react with oxygen and burn though technically it's oxidizing. An intense flame like that found in an Oxy-Acetylene torch will bring the steel to melting point, then the operator would toggle a lever on the torch blasting pure oxygen into the steel causing it to oxidize and fall away from the workpiece. The afore mentioned steel wool exercise illustrates the principle on metal so thin that the heat provided by a candle allows for oxidization with the oxygen present in the atmosphere.

- Q: What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its purpose and the industry it is being used in. However, in general, steel coils are often manufactured with a width ranging from 0.5 to 2 meters (1.6 to 6.5 feet) and a thickness between 0.1 to 25 millimeters (0.004 to 1 inch). The outer diameter of a steel coil typically ranges from 800 to 2,000 millimeters (31 to 79 inches), while the inner diameter, known as the core, can range from 500 to 1,000 millimeters (20 to 39 inches). These dimensions can be customized to meet specific requirements and can vary between different manufacturers and applications.

- Q: What is the role of steel coils in the production of appliances?

- Steel coils play a crucial role in the production of appliances as they serve as the primary material for constructing the outer bodies, frames, and internal components of various appliances. The coils are formed into desired shapes and sizes, ensuring durability, stability, and strength of the appliances. Additionally, the steel coils enable efficient heat transfer, enhancing the performance and longevity of appliances such as refrigerators, stoves, and washing machines.

- Q: I would like to build steel galvanization plant.

- Galvanising Plant

Send your message to us

Prepainted Steel Coil Without Anti-Dumping

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords