Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:DX51d SGCC DX52d

Surface Treatment:Coated

Certification:ISO, SGS

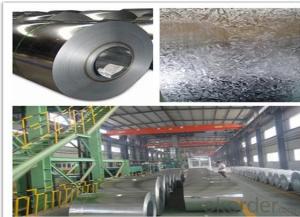

Technique:Hot Dipped

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Dx51d

Thickness:0.3mm

Width:1250mm

Top Paint:15+5

Back Paint:5-7

ID:508mm

Coil Weight:3-8 Tons

Zinc Coating:50g-250g/Psm

Gloss:65%-80%

Feedback:Within 24 Hours

Export Markets:Global

Additional Info.

Packing:Export Standard Package

Standard:AISI, ASTM, BS, DIN, GB, JIS

Origin:Shandong

HS Code:7210701000

Production Capacity:150, 000tons/Year

Product Description

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 30 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

Why Us:

1. ISO, BV, CE, SGS approved

2. Competitive price and quality from our own factory

3. Efficient service team online for 24 hours

4. Smooth production ability(50000tons/month)

5. Quick delivery and standard exporting package

6. Flexible payment with T/T, L/C, Paypal, Kunlun bank, etc

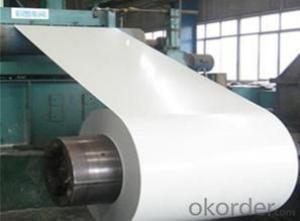

| Name | 0.3mm Thickness PPGI Prepainted Galvanized Steel Coil |

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 3-8 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000mm-1500mm |

| Zinc Coating | Z50-Z275G/psm |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

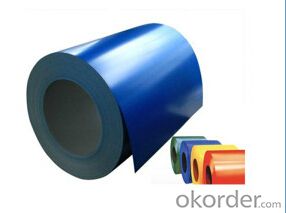

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation |

- Q: How are steel coils made?

- Steel coils are made through a process called hot rolling, where steel slabs are heated and passed through a series of rollers to reduce their thickness and increase their length. These coils are then cooled and coiled into large rolls, ready for use in various industries such as automotive, construction, and manufacturing.

- Q: How are steel coils used in the production of prefabricated buildings?

- Steel coils are used in the production of prefabricated buildings as they serve as a primary material for manufacturing structural components such as beams, columns, and frames. These coils are unrolled and shaped into various sections, which are then welded or bolted together to form the skeleton of the building. Their strength, durability, and malleability make steel coils an ideal choice for constructing robust and reliable prefabricated structures.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are commonly used in the manufacturing of medical equipment as they serve as a crucial component in various applications. These coils are often employed in the construction of medical devices such as surgical instruments, orthopedic implants, and diagnostic equipment. The high strength and durability of steel make it ideal for these purposes, ensuring the longevity and reliability of the medical equipment. Additionally, steel coils are used in the production of medical furniture, such as hospital beds and examination tables, providing stability and support. Overall, steel coils play an essential role in the manufacturing of medical equipment, contributing to the quality and functionality of these devices.

- Q: Also, what is the top best slow cooker that is 100% stainless steel? Thank you!

- My SS pans are Prestige.

- Q: I saw this really pretty ring online and it was made of steel. Is this a good ring? If I were to wash my hands with it on, would it rust and turn my finger green?

- Steel rust is brown not green! Very much expected to be of one type of stainless steel, and you should have no problem.

- Q: Does a magnet stick to galvinied steel?

- yes it does. The steel below the galvanized coating still has a relative high carbon content and magnets stick to it. Magnets do not stick to stainless steel very well though. There is a weak attraction there. If I recall correctly this is due to the relatively low carbon content and the higher content of chromium.

- Q: Are steel coils corrosion-resistant?

- Yes, steel coils can be made corrosion-resistant through various methods such as coating them with protective layers or using corrosion-resistant alloys.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

- Q: How do steel coils contribute to the construction equipment industry?

- The construction equipment industry relies heavily on steel coils as they are vital for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are crucial components used in the fabrication of a wide range of construction equipment, including cranes, bulldozers, excavators, loaders, and forklifts. The main contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is renowned for its exceptional mechanical properties, such as high tensile strength, toughness, and resistance to wear and corrosion. These properties make it an ideal material for constructing heavy-duty machinery capable of withstanding the demanding conditions of construction sites. Steel coils are employed in the production of the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be sturdy and able to endure heavy loads, impacts, and continuous use. Steel coils provide the necessary strength and reliability to ensure the long-lasting performance of construction equipment. Moreover, steel coils are also used to manufacture specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are essential for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material required for their production. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various sizes and shapes, allowing manufacturers to create equipment with specific designs and functionalities tailored to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they serve as the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the challenges of construction sites and ensure the safety and efficiency of construction projects.

Send your message to us

Prepainted Galvanized Steel Coils for Building Materials

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords