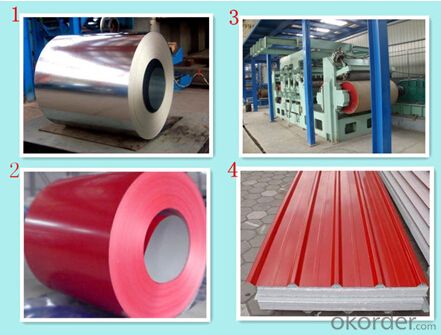

Prepainted Galvanized Steel Coil/PPGI Coil (Printed, Filmed, Matte)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Surface Treatment:Coated

Certification:SGS

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q235

Emboss Type:Wood Grain, Marble, Brick Grain, Camouflage

Base Sheet:HDG/Al-Zn/Zf

Thickness:0.13-1.5mm

Width:600mm-1500mm

Color:Ral Card Colors

Top Side:20-25um

Back Side:7-12um

Weight of Coil:3-5mt

Type:PE; Hdp; Smp; PVDF

Export Markets:Global

Additional Info.

Packing:Export Packing

Standard:0.13-1.5*600-1250MM

Origin:China

Production Capacity:300000 Mt/Year

Product Description

Specifications

1 thickness: 0.12-1.5mm

2 width: 600-1500mm(914/1000/1200/1220/1250mm)

3 Ral card colors available

Prepainted Steel Coil is made by galvanized steel sheets as substrate and coated by polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

Main Processing of PPGI Coil:

(1) The surface pretreatment including degreasing, cleaning, chemical conversion.

(2) Continuous coatings (roller coating method),

(3) Roasting and cooling.

PPGI/PPGL with light weight beautifal appearance and good corrosion resistance can be directly processed so it is widely used in light industry, househould, appliances, automotive and construction industry. For avrious types of industrial and civil construction industry, light steel keel, building level board, corrugated board, roller shutter doors. It was designed to protect steel surface from corrosion, extend its life, in the surface coating layer of Zinc and Color PE metal plate, making improvements to its surface characteristics of thin steel plate.

Printed and color coated heet is a new type of coated sheet which has high decoration performance, with protect, decorate, handsome dispose the coated layer surface. They are widely used in the field of electrical home appliances, decoration and special places.

Packaging & Delivery

Packaging Detail: Seaworthy standard export packing

Delivery Detail: Within 15-25 work days once we get the deposite.

| Available Size for ppgi ppgl color coated galvanized steel coil prepainted galvanized steel coil | |||

| Manufacturer | Thickness | Width | Inner Diameter of Coil |

| ZhengzhouCityUnites Steel Industrial Co., Ltd. | 0.13-1.5mm | 600-1500mm | 508mm,610mm |

| Available Painting for ppgi ppgl color coated galvanized steel coil prepainted galvanized steel coil | |||

| Category of Painting | Iterm | Code | |

| Polyester | PE | ||

| High-durability Polyester | HDP | ||

| Silicon Modified Polyesters | SMP | ||

| Polyvinylidene Fluoride | PVDF | ||

| Easy-cleaning | EC | ||

| Painting Thickness | Top side | 10-20±5microns | |

| Bottom side | 5-7microns | ||

| Back side | 5-7microns | ||

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: what happened to all the steel beams from the WTC buildings? did anyone do any forensic analysisof any of the steel?

- some of the steel was recycled into a warship. I am not sure at what you are trying to get at with the forensic analysis of the steel. There is no conspiracy involving the towers outside of planes crashing into them despite what a lunatic fringe want you to think.

- Q: How are steel coils inspected for oil or rust residues using chemical analysis?

- Steel coils can be inspected for oil or rust residues using chemical analysis by first collecting samples from various parts of the coil. These samples are then analyzed using appropriate chemical techniques such as solvent extraction or acid digestion to extract any oil or rust residues present. The extracted substances can be further analyzed using methods like Fourier transform infrared spectroscopy (FTIR) or atomic absorption spectroscopy (AAS) to identify and quantify the specific contaminants. This chemical analysis allows for a thorough inspection of steel coils and helps ensure their quality and suitability for various applications.

- Q: How are steel coils inspected for color consistency using colorimetry?

- Steel coils can be inspected for color consistency using colorimetry by measuring the color of the surface using a spectrophotometer. This device analyzes the reflected light and provides objective and precise color data. By comparing the color measurements of different areas of the coil, any variations in color consistency can be identified, allowing for quality control and ensuring the desired color uniformity throughout the coil.

- Q: What are the common methods of slitting steel coils?

- There are several common methods of slitting steel coils, each with its own advantages and applications. 1. Rotary Shear Slitting: This method involves using rotary cutting knives to slit the steel coil. The coil is fed through the rotary shear machine, and the knives make simultaneous cuts along the length of the coil. Rotary shear slitting is known for its high-speed operation and ability to handle thicker gauge materials. 2. Loop Slitting: Loop slitting is a method where the steel coil is fed into a looping pit, creating a loop of material. The loop is then pulled through a set of knives that make the slits. This method is commonly used for thin gauge materials and provides precise cuts with minimal burr. 3. Drag Slitting: In drag slitting, the steel coil is fed through a set of driven rolls or drag pads, which help to maintain tension on the material. The coil is then guided through circular knives that make the slits. Drag slitting is suitable for various gauges of steel and offers good accuracy and edge quality. 4. Crush Slitting: Crush slitting involves passing the steel coil through a set of rolls, where one roll is rubber-covered and the other is hard. The rubber roll compresses the material against the hard roll, creating the slits. This method is commonly used for thin gauge or delicate materials as it minimizes the risk of edge damage. 5. Laser Slitting: Laser slitting utilizes a high-powered laser beam to make precise cuts on the steel coil. This method is highly accurate and allows for complex slitting patterns and narrow width cuts. Laser slitting is often used for high-end applications that require superior edge quality. Each of these methods has its own advantages and is chosen based on factors such as material thickness, desired edge quality, production speed, and cost considerations. It is important to carefully select the appropriate slitting method to ensure the desired outcome and efficiency in steel coil processing.

- Q: How are steel coils used in the production of steel drums?

- Steel coils are used in the production of steel drums by being unwound and shaped into circular sheets. These sheets are then formed into the body of the drum, providing the necessary strength and durability.

- Q: What are the different methods of protecting steel coils from corrosion?

- There are several methods for protecting steel coils from corrosion. One common method is applying a protective coating, such as zinc or epoxy, which acts as a barrier between the steel surface and corrosive elements. Another approach is using corrosion inhibitors, which are chemicals that can be added to the storage environment or applied directly to the steel to reduce the rate of corrosion. Additionally, proper storage conditions, such as controlling humidity levels and preventing exposure to moisture and chemicals, can also help protect steel coils from corrosion.

- Q: How are steel coils processed for further use?

- Steel coils are processed for further use through a series of steps including uncoiling, leveling, cutting, and shaping. The coils are first uncoiled to separate them into individual sheets. Then, the sheets undergo leveling to remove any imperfections and ensure a flat surface. After that, the sheets are cut into desired lengths or shapes using precision cutting tools. Finally, the cut sheets are shaped according to the specific requirements of their intended application, such as bending, rolling, or stamping.

- Q: Help please.What atoms are there in steel?Like water is equals to 1 Oxygen atom + 2 Hydrogen atoms.Thnx 4 d help.

- Steel is mostly iron with a small amount (less than 1%) of carbon added. Stainless steel has other metals like chromium and nickel added.

- Q: What are the different methods of coil slitting for precision cuts?

- There are several methods of coil slitting for precision cuts, including rotary slitting, loop slitting, and double knife slitting. Rotary slitting involves using a circular blade to cut through the coil, while loop slitting utilizes a looping mechanism to create tension and then cuts the coil with a straight blade. Double knife slitting, on the other hand, employs two blades that move in opposite directions to cut the coil. These methods enable precise and efficient cutting of coils into narrower strips for various industrial applications.

- Q: Explain your answers please. I was watching mythbusters and they bought a steel coffin over a wooden one because they thought it would hold more dirt. Now how come bridges that have been made of wood lasted way longer than steel bridges? Or rollercoasts for example.

- Back when I was in school we used to have a contest comparing balsa wood bridge designs. The idea was to build the strongest bridge when derated for bridge weight. The strength test was that the 2-ft long bridge was placed between two tables and a garbage can was strung up to the middle of it. Then it was slowly filled with water until the bridge snapped. The can was weighed and divided by the bridge weight to get our scores. I don't see why you couldn't do this to compare wood vs steel. You could find how much load is needed to snap sample rods. The important point is that the rods should be nearly identical in dimensions between the two materials-- this means length and diameter. Also if you're measuring steel, you'd want to choose a relatively thin diameter or a long span or you won't be able to even bend it. Also while I'm pretty sure wood will snap, steel might bend gradually, so you'd have to decide how much deformation you would allow before calling the piece failed. Also if you take this approach be sure to wear safety glasses when running it. In fact it would be a good idea to put a metal shroud around the test structure.

Send your message to us

Prepainted Galvanized Steel Coil/PPGI Coil (Printed, Filmed, Matte)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords