Prepainted Galvanized Steel Coil/PPGI ASTM A653 High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Prepainted Galvanized Steel Coil/PPGI ASTM A653:

PPGI is the material which uses galvanized steel as the basic substrate metal. PPGI is prepainted galvanized steel, also known as precoated steel, coil coated steel, color coated steel etc.A galvanized steel sheet in coil form is cleaned, pretreated, applied with various layers of organic coatings which can be paints, vinyl dispersions, or laminates.These coatings are applied in a continuous process known as Coil Coating.The steel thus produced in this process is a prepainted, prefinished ready to use material.

2.Usage of Prepainted Galvanized Steel Coil/PPGI ASTM A653:

Outdoor: roof, roof structure, surface sheet of balcony, frame of window, door, garage doors, roller shutter door, booth, Persian blinds, cabana, refrigerated wagon and so on.

Indoor: door, isolators, frame of door, light steel structure of house, sliding door, folding screen, ceiling, internal decoration of toilet and elevator.

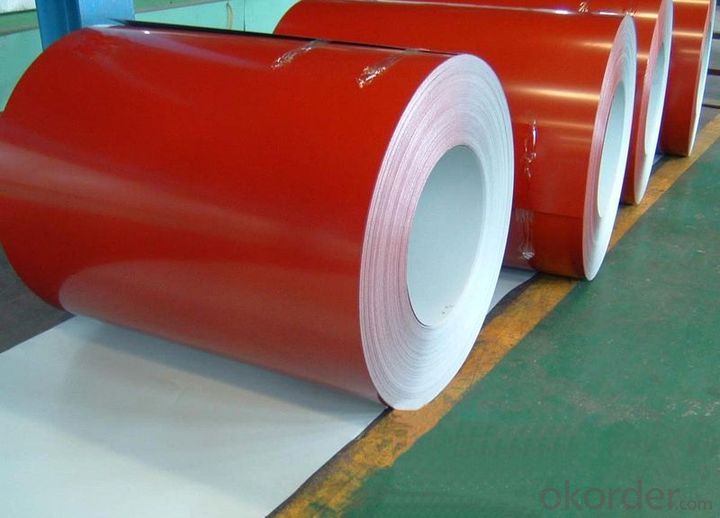

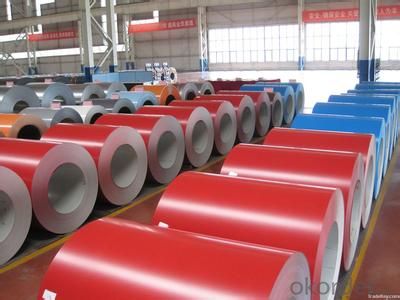

3.Prepainted Galvanized Steel Coil/PPGI ASTM A653 Images:

4.Prepainted Galvanized Steel Coil/PPGI ASTM A653 Specification:

Commodity | Prepainted Galvanized Steel Coil/Sheet | ||||

Standard | Q/BQB440 JISG3312 EN10327 | ||||

Grade | TDC51D/TDC52D/TDC53D/TS280GD/TS350GD/TS550GD/TSECC/TSECD/TSECE/CGCC/CGCC1/CGC400/ | ||||

CGC440/ CGC570/DX51D+Z/DX52D+Z/DX53D+Z/S280GD+Z/S350GD+Z/S550GD+Z/SECC/SECD/SECE | |||||

Thicknees | 0.14-0.8 mm | Width | 600-1250mm | ||

Zinc Coating | Z40-Z275g/m2 | Coil Weight(Min or Max) | 3-8 tons | ||

Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | ||

Color | Ral color | As Customers' requirement | |||

Surface Finish | Normal Coated | Embossed | Printed | ||

Category Of Finish Coating | High-durability Polyester | Silicon Modified Polyesters | |||

Polyvinylidene Fluoride | Polyester | ||||

Anti-static | Easy-Cleaning | ||||

Coating Type | Top Surface | Bottom Surface | |||

Double Coated | Double Coated | ||||

Double Coated | Single Coated | ||||

Coating Thickness | Top Surface: | Back Surface: | |||

Coating Structure | Primer | Finish Coating | |||

Epoxy Primer | Polyester | ||||

Polyester Primer | Silicon Modified Polyesters | ||||

Water-soluble Acrylic Acid Primer | High-durability Polyester | ||||

Polyurethane Primer | Polyvinylidene Fluoride | ||||

Method of Test | <1>Acid/Alkaline-Resistance Test | <2>Test of Resistance to Neutral Mist | |||

<3>Air Exposure Test | |||||

Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | |||

5.PACKING:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are steel coils secured during transportation?

- Steel coils are typically secured during transportation using metal bands or straps, which are tightly fastened around the coils to prevent them from shifting or falling off. Additionally, wooden blocks or dunnage may be used to provide stability and prevent movement within the transportation container.

- Q: How are steel coils formed into specific shapes?

- Coil slitting and coil forming are the two processes used to shape steel coils into specific forms. In coil slitting, a large steel coil is unwound and passed through rotating circular blades that cut it into narrower strips of the desired width. These strips are then rewound into smaller coils called slit coils. Once the steel strips have been slit, they can undergo coil forming to achieve the desired shapes. Coil forming involves various processes such as roll forming, stamping, bending, or pressing. Roll forming gradually shapes the steel strip by passing it through a series of rollers designed to bend it in specific ways. Stamping, on the other hand, uses a die and a press to cut or shape the metal into intricate forms. This method is preferred when high precision is necessary. Bending and pressing are also employed to manipulate the steel strip into desired curves or angles. Bending utilizes machines or tools to apply force, while pressing employs hydraulic or mechanical presses to shape the steel strip according to the mold or die design. In conclusion, the formation of steel coils into specific shapes involves both coil slitting and coil forming techniques. These techniques, including roll forming, stamping, bending, and pressing, enable manufacturers to transform steel coils into various shapes and profiles, catering to different applications in industries such as construction, automotive, and manufacturing.

- Q: What are the different types of steel coil handling equipment used during processing?

- There are several types of steel coil handling equipment used during processing, including coil cars, coil upenders, coil tilters, coil transfer cars, coil grabbers, coil lifters, and coil reels. These machines are designed to efficiently handle and maneuver steel coils of various sizes and weights, ensuring safe and smooth operations during the processing stages.

- Q: What are the limitations of using steel coils in certain applications?

- Steel coils have a few limitations that may restrict their use in certain applications. Firstly, steel coils can be heavy and bulky, making them less suitable for applications where weight reduction is crucial. For instance, in industries such as aerospace or automotive, where lightweight materials are preferred to enhance fuel efficiency and improve performance, steel coils may not be the most suitable choice. Secondly, steel coils are vulnerable to corrosion, especially in environments with high moisture or exposure to chemicals. This limitation can restrict their use in applications where resistance to corrosion is crucial, such as marine or coastal structures. Additional protective coatings or regular maintenance may be required to mitigate this limitation, adding to the overall cost and maintenance efforts. Moreover, steel coils may not possess the necessary flexibility or malleability required for certain applications. In industries such as construction or manufacturing, where materials need to be easily shaped or bent into specific forms, steel coils might not offer the desired level of flexibility. This limitation can lead to difficulties in achieving desired designs or may require additional processing steps to mold the steel coils into the desired shape. Lastly, steel coils can have limitations in terms of their temperature resistance. In high-temperature applications, such as in furnaces or power generation, steel coils may experience thermal expansion or deformation, which can compromise their structural integrity. In such cases, alternative materials with higher temperature resistance, such as refractory metals or ceramics, may be more suitable. Overall, while steel coils are widely used and versatile materials, their limitations in terms of weight, corrosion resistance, flexibility, and temperature resistance can restrict their use in certain applications. It is crucial to consider these limitations and assess the specific requirements of the application when selecting materials for optimal performance and durability.

- Q: I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or are stainless steel pans better for some applications?

- This Site Might Help You. RE: Why should I use stainless steel cookware? I received a very nice set of stainless steel cookware as a wedding gift. While very pretty, Im finding them almost useless for cooking. Everything sticks, they're difficult to clean, and Im using my old non-stick pans instead. Should I simply leave the stainless out for decortive purposes, or...

- Q: why were guns, germs and steel absent within America?

- i dont really understand this question but if it means to how it was before then it was absent because the native americans were not into technology so they obviously had no guns created that was something that they had traded to get from europe as for the germs i ddo not know about thta really except for if it means that common disease and one of the diseases most used in history books is malaysa from mosquitos but when they had traded with europe they got all sorts of diseases now for steel the only reason i remember them traveling for is for gold and i dont remember them ever looking for it until 13 colonies were established as you can see im not exactly sure about germs and steels but i know that the guns part is correct

- Q: Can steel coils be deep-drawn?

- Yes, steel coils can be deep-drawn. Deep-drawing is a metal forming process where a sheet or coil is drawn into a die cavity to create a three-dimensional shape. Steel coils, due to their high strength and ductility, are often used in deep-drawing applications to produce various products such as automotive parts, kitchen appliances, and containers.

- Q: What is the weight of a typical steel coil?

- The weight of a typical steel coil can vary significantly depending on its size, thickness, and type of steel used. However, a typical steel coil can range anywhere from a few hundred kilograms to several tonnes in weight.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are widely used in the manufacturing industry as they are essential for various applications such as automotive, construction, appliances, and machinery. These coils are commonly used to produce various metal components and parts, including sheet metal, pipes, tubes, and wire. The coils are unwound and fed into different machines and processes, where they are shaped, cut, stamped, or welded to create the desired products. Due to their durability, strength, and malleability, steel coils are highly valued for their versatility and play a crucial role in the manufacturing industry.

- Q: Question about steel type used in bridges.?

- It is used for other things besides bridges and that might be a bad use. Corten was used for very tall light standards in the Fort Worth Water Gardens with the clear understanding that it was to be kept dry. As time passed and personnel changed, somebody decided the round base with bolts sticking up was ugly and put dirt and plantings in the basin in the concrete holding the poles. The watering of the plants kept the rust going through the steel and one pole eventually fell, killing two people. The other light poles were removed.

Send your message to us

Prepainted Galvanized Steel Coil/PPGI ASTM A653 High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords