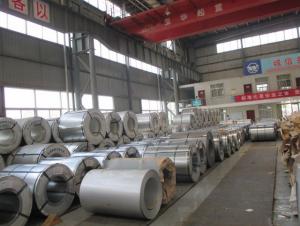

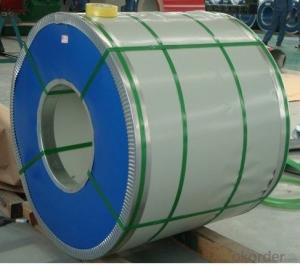

Prepainted Galvanized Steel Coil 0.22*914mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted galvanized color coated PPGI steel:

| Thickness | 0.12-1.2mm |

| Width: | 700-1250mm |

| Material: | SGCC,SGCD,SECC,SECD,DX51D+Z |

| Zinc coating: | 30-180G/M2 |

| Surface Structure: | galvanized ,zero spangle, regular spangle or normal spangle |

| COLOR: | RAL number or sample colour |

| Coating: | Topside: 5micron primer +15-20microns polyester Backside: 5-8microns primer epoxy. Surface treatment: chromated and oiled, chromated and non-oiled |

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as corrugated steel sheet 4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

- Q: What are the different types of steel coils available?

- There are several types of steel coils available, including hot rolled coils, cold rolled coils, galvanized coils, stainless steel coils, and coated coils.

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they provide a strong and durable core for the transformer. The coils are typically made of high-grade electrical steel, which has low electrical resistance and high magnetic permeability. These properties allow the coils to efficiently conduct and transform electrical energy, ensuring the proper functioning of the transformer.

- Q: How are steel coils used in the manufacturing of lighting fixtures?

- Steel coils are used in the manufacturing of lighting fixtures as they provide a sturdy and durable structure for the fixtures. The coils are typically shaped and formed to create the desired shape and design of the lighting fixture, ensuring its strength and stability. Additionally, the steel coils can be coated or painted to enhance the aesthetics of the fixture, making it more visually appealing.

- Q: Cast steel welding

- I Use these for cast iron, www.yms .uk/welding-rod-small-pack/2.5mm-cast-iron-welding-rod-small-pack/1951/11612/detail.asp they are expensive when compared to welding rods for steel but i find that normal steel ones dont work on cast iron

- Q: How do steel coils contribute to the transportation industry?

- The versatility and durability of steel coils play a significant role in the transportation industry. These coiled steel sheets have various uses, such as manufacturing automobiles, shipping containers, and railway cars. In the automotive sector, steel coils are utilized to produce different components like body panels, chassis, and engine parts. Steel's strength and malleability make it an ideal material for ensuring vehicle safety and durability. Additionally, steel coils are employed in manufacturing shipping containers, which are crucial for global goods transportation. The sturdiness and resistance to corrosion provided by steel coils ensure the protection of goods during their journey. Moreover, steel coils are essential in the railway industry. They are used to manufacture railway cars, including freight cars and passenger coaches. Steel's strength and durability make it ideal for withstanding the heavy loads and harsh operating conditions experienced by railway vehicles. Steel coils also contribute to the construction of railroad tracks and bridges, providing the necessary strength and stability for safe and efficient transportation. In conclusion, steel coils are indispensable in the transportation industry. They offer the required strength, durability, and versatility for manufacturing various transportation vehicles and infrastructure. Their contribution ensures the safety, reliability, and efficiency of transportation systems, making them vital in the modern world.

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: If you were selecting a tool steel for an extreme impact load application, which one would you pick? why?thanks

- It all depends what the application actually is. For hammers I would select a hammer grade B1 steel. For impact loading where an edge is needed I would be going for O1 or similar (oil quenching steels tend to be a little tougher than air hardening). For mining tools a very high manganese steel (Hadfields steel) - this is not a true tool steel. The best place to start is by looking at the ranking of the properties which you want - hardness v toughness v strength - and then use this to put the steels in rank order. Price and availablity then sort the problem out for you (in the real world).

- Q: Went to top gun range in Houston, Tx. Guy there said no steel bullets..Anyone know why? Think i can shoot them anywhere else? Perhaps an outdoor gun range? The are monarch FMJ 9mm steel rounds..Thanks!

- Top Gun Range Houston

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: I am trying to make a homemade fender eliminator for my motorcycle and the instructions from the site I found said to use 22 gage weld steel. I went to lowes and all they had was 26 gage sheet metal. What is the difference between the two? Is weld steel less flexible?

- galvanized steel gives off poisonous fumes when you weld it

Send your message to us

Prepainted Galvanized Steel Coil 0.22*914mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords