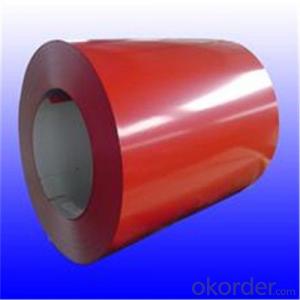

Prepainted Galvanized Rolled Steel Coil/Sheet/Plate from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Prepainted Galvanized Steel:

Prepainted Galvanized Steel usually refers to have substrate processed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed to final production .

Prepainted Galvanized Steel qualified with excellent decorative, formability, corrosion resistance, coating adhesion ,can keep for a long time as well as maintain fresh color .For color coated steel sheet can obtain good economic benefit by steel belt wood ,efficient in construction and save energy ,prevent pollution etc. Which is an ideal material; for manufacturing board.

Description of Prepainted Galvanized Steel:

1.material : galvanized steel sheet / prepainted galvanized sheet

2.sheet thickness : normal use 0.3-0.6mm

3.length: any length, according to the transportation, generally less than 12m

4.color: standard color: red, blue, white, grey; special color: according to RAL color

Specification of Prepainted Galvanized Steel:

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Images of Prepainted Galvanized Steel:

- Q: What are the typical lead times for ordering steel coils?

- The typical lead times for ordering steel coils can vary depending on several factors, including the supplier, the quantity and specifications of the coils, as well as the current market conditions. However, on average, lead times can range from a few weeks to a couple of months. It is always recommended to contact the specific supplier for more accurate information regarding lead times.

- Q: What are the dimensions of steel coils used in the power generation industry?

- The dimensions of steel coils used in the power generation industry can vary depending on the specific application and requirements. However, in general, steel coils for power generation are typically available in various sizes and thicknesses. The width of steel coils used in power generation can range from a few inches to several feet, depending on the specific equipment or machinery they are intended for. These coils are often designed to fit specific manufacturing processes or components within power generation systems. The thickness of steel coils used in the power generation industry can also vary significantly. Thicker coils are commonly utilized for heavy-duty applications that require increased strength and durability, while thinner coils may be suitable for less demanding tasks or where weight reduction is a priority. Additionally, the weight of steel coils used in power generation can vary depending on their dimensions and the specific steel material being used. The weight is an essential consideration during transportation, installation, and handling of the coils. It is important to note that the dimensions of steel coils used in the power generation industry can be customized to meet specific project requirements. Manufacturers typically work closely with power generation companies to understand their needs and provide tailored solutions that meet their dimensional specifications.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: How are steel coils processed for slitting or shearing?

- Steel coils are processed for slitting or shearing by feeding the coil through a slitter or shear machine, which cuts the coil into narrower strips or various shapes, respectively. This process involves unwinding the coil, straightening it, and then passing it through the slitting or shearing machine, where precise cuts are made according to the desired dimensions. The resulting strips or shapes are then collected and packaged for further use or distribution.

- Q: How are steel coils inspected for color consistency?

- Steel coils are inspected for color consistency using a variety of methods to ensure that the final product meets the desired specifications. One common method is visual inspection, where trained inspectors examine the steel coils under controlled lighting conditions to detect any variations in color. This is done by comparing the color of each coil to a standard color chart or a previously approved sample. Any discrepancies are noted and further analysis is conducted. Additionally, advanced technologies such as spectrophotometers may be employed to measure the color of the steel coils objectively. Spectrophotometers use light to measure the reflective properties of the steel surface, allowing precise color analysis. The obtained color data is then compared to the specified color range, and any deviations are flagged for further investigation. Furthermore, some manufacturers may use automated color measurement systems, such as colorimeters or color cameras, to inspect steel coils for color consistency. These systems can quickly and accurately assess the color of each coil, ensuring uniformity across the entire batch. Overall, the inspection of steel coils for color consistency involves a combination of visual inspection, spectrophotometry, and automated color measurement systems. This comprehensive approach helps to guarantee that the steel coils meet the required color standards, providing consistent and high-quality products to customers.

- Q: Can steel coils be stamped?

- Yes, steel coils can be stamped. Stamping is a common process used to shape and form steel coils into various shapes and sizes for different industrial applications.

- Q: I have heard of Cold Rolled steel, Castle Forged steel and Valerian steel and i was just wondering the difference between them.I know Valerian steel is by far the strongest and durable but what about the other two types? Do you know because i haven't read all the books yet.

- Cold rolled steel is referring to rolled steel. It is referring to weapons made from rolled steel that is unrolled and stamped out. In real-life, rolled steel isn't nearly as strong as steel that is cast and forged. Think of a cheap dinner fork that you can easily bend and a nice dinner fork you can't bend at all. The cheap fork is stamp-pressed out of rolled steel and the nice fork is cast. In Game of Thrones, cold rolled steel is crap, but it's cheep and common. Castle forged steel is the best most people have available, much higher quality than cold rolled steel. Presumably it's forged in the castles of Westeros, including King's Landing. Valerian steel is special, rare steel that was anciently forged that is stronger than any other steel. They no longer make Valerian steel since the fall of Valeria. As such, the only Valerian steel available is by getting it from things already made. In real-life, it might be comparable to the extremely high quality steels forged into ancient katanas, ninja fighting swords from Japan. The Lanisters took a sword made of Valerian steel that had been passed down to Ned Stark and had it melted down, recast, then forged into two smaller swords.

- Q: Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appeal, protect against corrosion, and improve durability.

- Q: How are steel coils used in the production of storage tanks?

- Steel coils are typically used as the raw material in the production of storage tanks. These coils are formed into sheets and then shaped and welded to create the tank's body. The strength and durability of steel make it an ideal choice for storing various substances, including liquids and gases, ensuring the safety and longevity of the storage tanks.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- The reason the steel wool catches fire is because the strands of steel are so fine and they have a high resistance. The thin strands get to red-hot very quickly, compared to larger gauge copper wire which has lower resistance and can dissipate the heat over its larger mass. When you connect the battery to the wire first, then touch the steel wool, you are making solid contact with the steel wool and your hand makes sure that the wire stays in contact. The current continues to flow and the wool heats up. When you connect the wire to the steel wool first, as soon as you connect the battery the current melts that tiny bit of steel wool touching the wire and electrical contact is lost. The current stops flowing. No fire. If you want to connect the wire first and not have to hold it, you have to make sure that the current keeps flowing, perhaps by using a braided copper wire and spreading out the individual strands to make multiple contacts. Either that, or remove the insulation from a longer section of the wire and make sure that the entire un-insulated part of the wire is in contact with the steel wool. Maybe even weigh it down. Remember that any strands of steel wool touching that wire will melt as soon as the current starts, so you have to make sure that the wire will maintain contact somehow, the same way that your hand pushes the wire against it.

Send your message to us

Prepainted Galvanized Rolled Steel Coil/Sheet/Plate from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords