Prepainted galvanized Rolled Steel Coil -CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

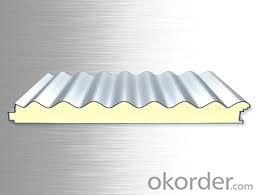

Description: Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion . PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board. Applications: It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance. Packaging & Delivery: The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky). Images:

|

- Q: The hard industrial steels. If there's a bunch, what's a rough average? Also, what is is measured in?

- The general purpose default steel for hard tooling applications is A2 It's cheap, readily available and comes in many different shapes and sizes. It's easy to machine soft. It's easy to harden, you can do it yourself. It is very dimensionally stable during hardening. All the steels mentioned above are specialty steels - expensive to buy, hard to work with, expensive to heat treat and dimensionally unstable during heat treat.

- Q: How are steel coils used in the manufacturing of engine components?

- Steel coils are used in the manufacturing of engine components as they provide strength and durability. They are typically processed and shaped into various parts such as connecting rods, crankshafts, and camshafts, which are essential for the engine's functionality. The coils are formed, machined, and heat-treated to meet the precise specifications required for each component, ensuring optimal performance and reliability in engines.

- Q: How long do steel coils typically last?

- Steel coils typically last for decades. The lifespan of steel coils can vary based on several factors including the quality of the steel used, the level of maintenance and care, and the specific application they are utilized in. Generally, steel coils are designed to be durable and resistant to corrosion, ensuring a long lifespan. With proper care, regular maintenance, and adherence to recommended usage guidelines, steel coils can last anywhere from 20 to 50 years or even longer. However, it is important to note that the lifespan can be influenced by external factors such as exposure to harsh environments, extreme weather conditions, and the level of stress or load they are subjected to.

- Q: The strip tower height

- Definition and appearance: the ends of the steel coils are uneven, one circle higher than the circle, showing a different degree of pagoda shape or bread shape.

- Q: What are the challenges faced during steel coil processing?

- There are several challenges that can be encountered during steel coil processing. One of the main challenges is ensuring proper handling of the steel coils. Steel coils are heavy and can weigh several tons, so it is crucial to have the correct equipment and procedures in place to safely move and manipulate the coils. This includes using cranes, forklifts, or other lifting devices that are strong enough to handle the weight and size of the coils. Another challenge is maintaining the integrity of the steel coils during processing. Steel coils are susceptible to damage from scratches, dents, or other forms of physical deformation. It is important to have proper storage and handling procedures in place to minimize the risk of damage. Additionally, care must be taken during cutting, slitting, or other processing operations to ensure that the coils are not damaged or compromised. Quality control is another significant challenge in steel coil processing. It is essential to consistently produce coils that meet the required specifications, such as thickness, width, and surface quality. This requires meticulous inspection and monitoring throughout the entire processing chain, from receiving the raw material to the final product. Any deviations from the desired specifications can result in rejected coils or customer dissatisfaction. Efficiency and productivity are also challenges in steel coil processing. The processing operations need to be optimized to minimize waste, reduce downtime, and maximize throughput. This can involve implementing automation, improving production planning, and streamlining the workflow. Additionally, balancing the production speed with maintaining quality standards is crucial to ensure efficient and productive processing. Lastly, safety is a significant challenge in steel coil processing. The nature of the equipment and processes involved poses various risks to workers, including the potential for accidents, injuries, or exposure to harmful substances. It is vital to have proper safety protocols in place, provide adequate training to employees, and regularly inspect and maintain the equipment to ensure a safe working environment. In summary, the challenges faced during steel coil processing include handling the heavy coils, maintaining their integrity, ensuring quality control, optimizing efficiency and productivity, and ensuring a safe working environment. By addressing these challenges, steel coil processors can achieve smooth operations and deliver high-quality products to their customers.

- Q: What are the different methods of coil leveling?

- Various industries commonly utilize several methods for coil leveling. These methods encompass: 1. Roller leveling: By passing the coil through a sequence of rollers, pressure is applied gradually, resulting in the gradual flattening of the coil. The rollers can be adjusted to exert varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: This technique subjects the coil to tension forces, elongating the material and eliminating internal stresses. As the coil is stretched while passing through rollers, a more uniform and flat surface is achieved. 3. Temper leveling: Involving the heating of the coil to a specific temperature followed by rapid cooling, this method helps equalize stresses within the coil and enhance its flatness. Temper leveling is often employed for high-strength steels. 4. Roller leveling with leveling rolls: This approach utilizes additional leveling rolls placed above and below the main leveling rollers. These rolls apply pressure to specific areas of the coil, rectifying any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil during processing. The tension aids in straightening and flattening the material, resulting in a more even and flat surface. 6. Precision leveling: Employed for high-precision applications necessitating extremely flat and uniform coils, precision leveling combines roller leveling, stretch leveling, and other corrective measures to attain the desired flatness. Each of these methods possesses unique advantages and limitations. The selection of a particular method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc or another protective coating is applied to the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel and minimizing the risk of corrosion. Additionally, steel coils are often stored in dry, enclosed spaces or wrapped with moisture-resistant materials such as plastic or wax paper to further protect them from humidity.

- Q: What are the common thickness tolerances for steel coils?

- The common thickness tolerances for steel coils usually range from +/- 0.001 to +/- 0.005 inches, depending on the specific industry standards and customer requirements.

- Q: What is the process of recycling steel coils?

- The process of recycling steel coils involves several steps. First, the steel coils are collected from various sources, such as manufacturing and construction sites. Next, the coils are transported to a recycling facility where they undergo a thorough inspection and sorting process. The coils are then cleaned to remove any contaminants or impurities. After cleaning, the steel coils are shredded into smaller pieces and melted down in a furnace. The molten steel is then molded into new coils or other steel products. Finally, the recycled steel coils are tested for quality and can be used in various industries, reducing the need for new steel production and minimizing waste.

- Q: I wanted to know what is steel fabricating?

- Steel Fabricating/or Steel Fabricators is just a fancy way of saying that they sell steel products and a variety of related services. Thomas steel products has a wide range of steel products and services, from Windsor Republic Door Dist, Tie Wire, Steel Doors Frames, Snap Ties, S Parker Hardware Distributor, Reinforcing Steel Detail Drawings Avail, Rebar Fabrication, o_O.

Send your message to us

Prepainted galvanized Rolled Steel Coil -CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords