Prepainted Aluminum Zinc Rolled Coil For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

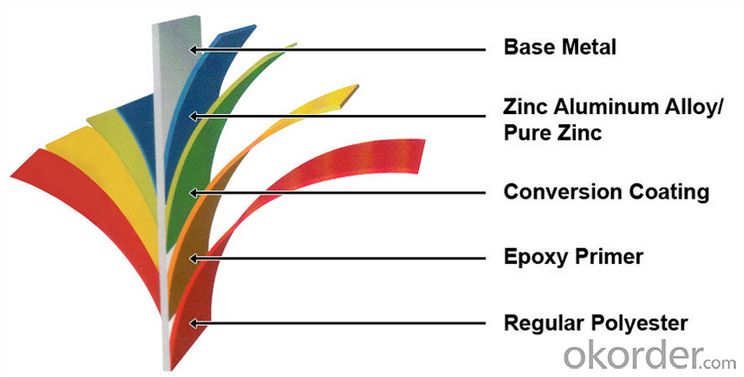

Structure of Prepainted Aluminum Zinc Rolled Coil For Construction

Description of Prepainted Aluminum Zinc Rolled Coil For Construction

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Aluminum Zinc Rolled Coil For Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Aluminum Zinc Rolled Coil For Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Prepainted Aluminum Zinc Rolled Coil For Construction Images

Specifications of Prepainted Aluminum Zinc Rolled Coil for Construction

Commodity | Hot Dipped Galvalume Steel Coil/Sheet | |||

Standard | JIS G3321 / ASTM A792M / EN10215 | |||

Grade | SGLCC/SGLCD/SGLC490/SGLC570/CS TypeA,B,C/DS/255/DX51D+AZ/DX52D+AZ/S250GD+AZ/S350GD+AZ/S550GD+AZ | |||

Chemical Composition | 55%Al,43.5%Zn,1.5%Si | |||

Thicknees | 0.16-2.0 mm | Width | 600-1250mm | |

Aluzinc Coating | AZ30-AZ200 g/m 2 | Coil Weight(Min or Max) | 3-8 tons | |

Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | |

Surface Treatment: | <1>Oiled | <2>Unoiled | <3>Slightly Oil | <4>Chromated Passivated |

<5>Skin Pass | <6>Anti Finger Print | |||

Surface Structure | Mini/Small Spangle | |||

Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | ||

FAQ of Prepainted Aluminum Zinc Rolled Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: I noticed a friend's appliances are not magnetic, and mine are. Both are stainless steel. Are there two types of stainless steel or something? Thanks

- There are many types of stainless steel. Some are magnetic and some are non-magnetic. The magnetic properties of stainless steel are very dependent on the elements added into the alloy, and specifically the addition of nickel can change the structure from magnetic to non-magnetic. Poor heat treatment or high heat input welding of normal or high carbon austenitic stainless steels will cause sensitization, ie formation of chromium carbides. The formation of carbides not only reduces the corrosion resistance of the stainless steel but also tends to form martensite around the carbide. This martensite is magnetic and the more severe the sensitisation, the stronger are the magnetic properties. When nickel is added, for instance, the austenite structure of iron is stabilized. This crystal structure makes such steels non-magnetic and less brittle at low temperatures. Martensitic stainless steels are magnetic. *Wrought, austenitic stainless steels, such as 304 and 316, are generally regarded as non-magnetic in the annealed condition, ie they are not attracted significantly by a magnet. However, if they are cold worked they will be attracted to a permanent magnet. The change occurs because the cold work deformation induces a transformation of the microstructure from austenite to martensite. The effect is less marked in alloys with high concentrations of austenite stabilisers such as nickel, nitrogen and carbon. Once the martensite is formed, it may also become magnetised. *In contrast to the austenitic alloys, ferritic stainless steels such as 409 or 3Cr12/5Cr12 and martensitic stainless steels such as 420, are strongly attracted to a magnet even in the annealed state. The duplex and super-duplex stainless steels will also be strongly attracted because they contain about 50% ferrite in their microstructure. *

- Q: I'm sort of a sword maker. You could say I'm an amateur blacksmith. I want to find a dependable source of high-grade steel. I've made a few blades and from what I know about the difference between true steel and cheap steel, I have yet to work with such. All of the metal I have used could not have been true high carbon spring steel because while they are hard, their properties do not reflect that of true steel. I would sincerely appreciate any guidance on where I could order some fine-quality steel so I could produce a truly fine blade.

- Here okorder

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. This coating process involves applying a thin layer of holographic material onto the surface of the steel coils, creating a visually striking and distinctive holographic pattern.

- Q: How are steel coils cut into smaller sizes?

- Steel coils are cut into smaller sizes using a machine called a slitting line. This machine employs a set of circular blades that cut through the steel coil, creating narrower strips or sheets of the desired size. The slitting line can adjust the width of the cuts and can also remove any rough edges or burrs.

- Q: How are steel coils used in the production of construction equipment?

- Steel coils are used in the production of construction equipment as they are a crucial raw material for manufacturing various components such as frames, beams, plates, and structural parts. These coils are processed through cutting, bending, and welding techniques to form the required shapes and structures used in the construction industry.

- Q: please i need your help in answering this question manufacturing process of steel containers and 20 references

- There are many types of steel containers and many different mnfg processes. There are also thousands of different steel alloys. Steel is used for canned food, compressed air cyclinders, hydraulic pressure vessels, electrical boxes, and many other containers. Steel containers are made out of sheet metal by soldering, brazing, spot welding, seam welding, riveting, bolting, screwing, etc. Heavier wall containers are fabricated of plate steel. Some steel containers are made by deforming the steel by extruding, forging, spin forming, drawing, ironing, etc. Some steel containers are made by machining. You should be able to find plenty of references if you search for these terms. good luck

- Q: How are steel coils used in the production of industrial valves?

- Steel coils are used in the production of industrial valves as they provide a high-strength and durable material for constructing the valve bodies, stems, and other components. The coils are typically shaped, cut, and formed into various valve parts, which are then assembled and welded together to create the final valve product.

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are applied to the surface of the steel coils to provide added protection against wear and tear caused by friction and other abrasive forces. This coating helps prolong the lifespan of the steel coils and maintain their performance in various applications.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are a critical component in the production of steel plates. They serve as the primary raw material for manufacturing steel plates. The process begins with the production of steel coils, which are created by heating and cooling molten steel to form thin, flat strips. These coils are then processed further in a rolling mill, where they are passed through a series of rollers to reduce their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are then uncoiled and straightened. This process involves feeding the coils through a machine that removes any curvature or deformities, ensuring the strips are completely flat. The straightened coils are then cut into specific lengths to suit the required dimensions of the steel plates. After being cut, the coils undergo another crucial step known as leveling. This process involves passing the strips through a leveling machine, which eliminates any residual stress or warping that may have occurred during the production process. Leveling ensures that the steel plates have a uniform thickness and are free from any distortions, making them suitable for various applications. Once the leveling process is complete, the steel coils are finally transformed into steel plates. These plates can be further processed based on the desired end-use. They may undergo additional treatments such as heat treatment, surface finishing, or coating to enhance their strength, durability, and corrosion resistance. In summary, steel coils are the starting point for the production of steel plates. They undergo several crucial steps, including rolling, uncoiling, straightening, cutting, and leveling, to transform them into flat, uniform steel plates. These plates can then be further processed and customized for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: Is there a difference between hot rolled and cold rolled steel coils?

- Yes, there is a difference between hot rolled and cold rolled steel coils. Hot rolled steel coils are produced at high temperatures and have a rougher surface, while cold rolled steel coils are produced at lower temperatures and have a smoother surface. Additionally, hot rolled steel coils are typically used for applications that require less precise dimensions and a more cost-effective option, while cold rolled steel coils are ideal for applications that require higher precision and a superior finish.

Send your message to us

Prepainted Aluminum Zinc Rolled Coil For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords