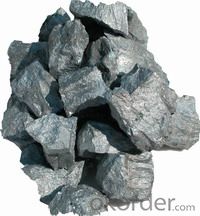

Raw Materials for Refractory:Premium Nodulizing Agent Inspection - CIQ SGS QA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

controlled composition &size

nodular cast iron

manufacture

MOQ: 20 tons

Inspection: CIQ SGS QA

High energy efficient in steelmaking

13 years' manufactural experience

Advantages

(1) Improve steel quality, reduce the cost and save aluminum, it is especially applied in continuous casting steel of deoxidizing requirements.

(2) It can not only meet the deoxidizing requirments of steelmaking, but also have the performance of desulphurization, in addition have advantages of big specific gravity and strong penetration

Specs of Ferro Silicon Magnesium

Brand | Code Name | Chemical Composition(%) | |||||

Mg | Re | Si | Ca | Al | Fe | ||

FeSiMg6Re1 | 6-1 | 5.0-7.0 | 0.5-1.5 | 38-44 | 2.0-3.0 | <1.0< span=""> | Balance |

FeSiMg7Re1 | 7-1 | 6.0-8.0 | .05-1.5 | 38-44 | 1.0-1.5 | <1.0< span=""> | Balance |

FeSiMg5Re2 | 5-2 | 4.0-6.0 | 1.0-3.0 | 38-44 | 2.0-3.0 | <1.0< span=""> | Balance |

FeSiMg7Re3 | 7-3 | 6.0-8.0 | 2.0-4.0 | 38-44 | 2.0-3.5 | <1.0< span=""> | Balance |

FeSiMg8Re3 | 8-3 | 7.0-9.0 | 2.0-4.0 | 38-44 | 2.0-3.5 | <1.0< span=""> | Balance |

FeSiMg8Re5 | 8-5 | 7.0-9.0 | 4.0-6.0 | 38-44 | 2.0-3.5 | <1.0< span=""> | Balance |

FeSiMg8Re7 | 8-7 | 7.0-9.0 | 6.0-8.0 | 38-44 | 2.0-3.5 | <1.0< span=""> | Balance |

FeSiMg10Re7 | 10-7 | 9.0-11.0 | 6.0-8.0 | 38-44 | 2.0-3.5 | <1.0< span=""> | Balance |

- Q: What are the refractory stocks?

- The company produces energy saving, environmental protection type functional refractory materials and unshaped refractory materials. It is the main functional refractory material and unshaped refractory production enterprise in china. Company's products to new green high-quality refractory materials, energy saving and environmental protection as the leading iron and steel industry technological progress and improve the level of technology and equipment to adapt to meet the "development policy" refractories industry to develop industry, has a strong competitive advantage in the market. The main domestic refractory products company can only use part of the products of refractory materials production of iron and steel industry, iron and steel industry production and Pu resistant can be used in the vast majority of refractory products, iron and steel industry with the most complete refractory products. Therefore, the future development of the company is closely related to the prosperity of the iron and steel industry. More than more than 2000 enterprises in refractory industry, the company is the largest supplier of refractory materials in China, and the market share is less than 2%. Iron and steel group integration will inevitably lead to the overall contract cost control, supplier refractory decreases by seventy or eighty to two or three. The company's overall contract accounted for 37% (Montreal 68%), the overall contract increase will enhance the market share and profitability. China's urbanization, industrialization and investment in the 4 trillion infrastructure will stimulate sustained and rapid growth of China's steel demand. Therefore, in the long run, the prospects for the development of refractories for iron and steel are broad.

- Q: What kinds of fireproof and fire retardant materials are there?

- recommend new Nano-insulation refractory insulation material Aerogel material, which consists of 99% pores of different sizes. it is not only the lightest and the most remarkable insualting material, but also having hydrophobic porous particles. 1830s invention.It has low thermal conductivity,not susceptibale to electrical, thermal and impact of sound with strong physical stability. It is a good insulator, but also has a strong impact resistance, three times the weight of the same volume of air. It is not heavy and can be used as heat insualting materials,buffer?materials, sound proof materials. It has attracted world attention and will be widely used in the future. Aerogel (Aerogel) features: Nontoxic to humans, insoluble in water, no burning, odorless, the world's lightest, low thermal conductivity. Aerogel heat shield is a new industrial insulation products. New products based on nanotechnology materials Aerogel, Aerogel materials in foreign countries has been widely used. We find it a lot better than the traditional insulation materials. To this end, the company introduced the product to China to open the Chinese market and import the best insualting materials to oil refining, electric power, shipbuilding, chemical, industrial pipelines, aerospace, machinery and equipment industries.

- Q: Does anyone know the refractory temperature of fire-resistant glass?

- Ordinary glass will be completely liquefied in the furnace of about 1100 degrees for half an hour and will not deform below 600 degrees. toughened glass fire-resistant glass is the product of ordinary glass after being processed Glass will mainly burst after encountering fire. When unevenly heated or encountering sudden drastic changes in temperature, ordinary glass will burst if the sharp temperature difference is over 70-120 degrees and toughened glass will burst at 200 degrees. It is not yet clear of the bursting temperature for the refractory glass. (I hope this answer can help you!) Hope you adopt !)

- Q: What problems should be paid attention to while using refractory materials under a controlled atmosphere?

- Pay attention to the performance of the materials, and the use of non oxide materials!

- Q: How can refractory material of the electric furnace be used for longer.

- Minimize mechanical shock, Electrical furnace commonly referred to must be electrical arc furance. The wall of electric arc furnace should be constrcuted with magnesite carbon brick. Its hearth permanent layer should be constrcuted with mansornary magnesia brick. High alumina brick is usually used to aviod furnace cover suddenly get hot and cold. But its service life is lower. At present integral casting furnace cover is made of alumina magnesia. Terminal will be created even without the use of refractory material. Consumption is much faster if using refractories material or whole knottiing mainly.

- Q: What are the features of construction class A fire resistant door ?

- 1, fireproof and thermal insulation Foam cement board is a Class A non-combustible inorganic heat preservation material which has good fireproof?performance can remain integrity after 3 hours baking at 1200℃. It can be used in buildings to improve fireproof?performance.

- Q: How to choose refractory material

- Refractory fiber in different furnace material requirements are different, I would like to know is methanol as a protective gas, fire fiber, cotton material what?.

- Q: Detailed description of magnesia dolomite refractory material?

- The use of low chromium or chrome free refractories is more and more widely used, developed countries in the development of chrome free refractories to replace the chromium containing material, through research and production practice show that dolomite refractories is the refining of AOD furnace, large cement kiln ideal material.

- Q: What are the materials used in refractory material processing?

- AZS special refractory brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on. Unshaped refractory materials commonly used are fettling, refractory ramming material, refractory castable, refractory plastic material, refractory clay, refractory gunning, refractory cast material, fireproof coating, lightweight castable, mud etc..

- Q: What's the fire endurance of A grade fireproof glass curtain wall?

- According to the latest requirement, fire door has three types of FMA, FMB and FMC, of which A, B, C refer to the class. Take FMA as an example, it refers to A class fire door (namely thermal insulation fire door). The fire endurance of these three types all can be 0.5h, 1.0h, 1.5h, 2.0h or 3.0h, and the specific fire resistance time needs to be determined by the design. Generally the design drawing will make clear of it. As to A class fire door, its fire endurance is 1.5h.

Send your message to us

Raw Materials for Refractory:Premium Nodulizing Agent Inspection - CIQ SGS QA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords