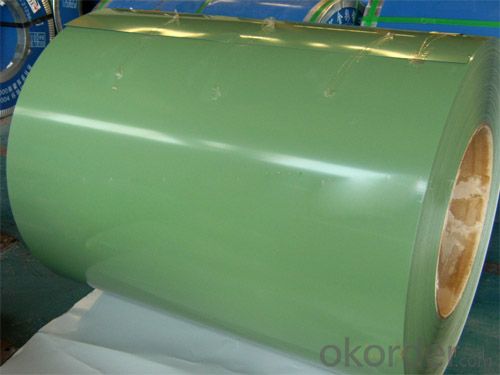

Pre-Painted Galvanized Steel Sheet/Coil with Prime Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps. Initially, the steel is cleaned and pickled to remove any impurities. It is then passed through a series of rolling mills to reduce its thickness and increase its length. The coils are then annealed to improve their strength and ductility. Further treatments such as galvanizing or coating can be applied to enhance corrosion resistance or improve aesthetic appeal. Finally, the coils are cut and packaged according to customer specifications before being shipped for various applications in industries such as construction, automotive, and manufacturing.

- Q: What are the advantages of using steel coils in construction?

- There are several advantages of using steel coils in construction. Firstly, steel coils offer exceptional strength and durability, making them suitable for supporting heavy loads and withstanding harsh environmental conditions. Additionally, steel coils provide a high degree of flexibility, allowing for customization and versatility in construction projects. Moreover, steel coils are fire-resistant and non-combustible, enhancing the safety of structures. Furthermore, they have excellent corrosion resistance, requiring minimal maintenance and ensuring long-term structural integrity. Lastly, steel coils are readily available and cost-effective, making them a preferred choice in the construction industry.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Yes, steel coils can be used in the manufacturing of machinery and equipment. Steel coils have high strength and durability, making them suitable for various applications in the machinery and equipment industry. They can be shaped, cut, and formed into various components, such as frames, shafts, gears, and structural parts, to meet the specific requirements of different machinery and equipment. Additionally, steel coils can be further processed and treated to enhance their properties, such as through heat treatment or surface coatings, to improve their performance and longevity in the manufacturing process.

- Q: What are the different methods of welding steel coils?

- There are several different methods of welding steel coils, each with its own advantages and applications. The most common methods used in welding steel coils include: 1. Resistance Welding: This method uses pressure and electric current to generate heat and join the steel coils together. It is commonly used for high-speed production and can be further categorized into spot welding, seam welding, and projection welding. 2. Arc Welding: This method involves creating an electric arc between an electrode and the steel coils, which generates intense heat and melts the metal. There are various types of arc welding techniques, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). 3. Laser Welding: Laser welding utilizes a highly focused laser beam to melt and join the steel coils together. This method offers precise control, high welding speeds, and minimal heat-affected zones, making it suitable for thin materials and intricate designs. 4. Electron Beam Welding: This technique employs a concentrated beam of high-velocity electrons to melt and fuse the steel coils. It is commonly used for welding stainless steel and other high-temperature alloys, as it provides deep penetration and minimal distortion. 5. Friction Stir Welding: In this method, a rotating tool with a pin is plunged into the steel coils, creating heat through friction. The softened material is then stirred together to form a solid joint. It is commonly used for joining aluminum, but can also be applied to steel coils. 6. Ultrasonic Welding: Ultrasonic welding involves applying high-frequency vibrations to the steel coils, which creates friction and generates heat to fuse the materials together. This method is commonly used for smaller steel coils and can provide fast and efficient welding with minimal distortion. These are some of the different methods of welding steel coils, each offering unique advantages and suitable for specific applications. The choice of welding method depends on factors such as the type and thickness of the steel, desired strength and quality of the weld, production speed, and cost considerations.

- Q: What are the different grades of steel used in coil manufacturing?

- There are several grades of steel used in coil manufacturing, including but not limited to, low carbon steel (e.g., ASTM A36), high carbon steel (e.g., ASTM A684), stainless steel (e.g., AISI 304), and galvanized steel (e.g., ASTM A653). These grades are chosen based on the desired properties and requirements of the coil being manufactured.

- Q: Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything like that, if not then I need to know what are other ways of testing the 1944 penny.

- This Site Might Help You. RE: 1944 Steel Penny? Is there any other way of testing whether or not you have a 1944 Steel penny that won't damage the penny. The magnet test doesn't seem to work cause even when I try to get a 2007 penny to stick to the magnet...it won't. So is there some kind of magnet needed? Like power wise or anything...

- Q: what do we use steel for and whyand why do we use brass for instrumentsplz help its homework and i cant find the answer anywhere : (

- Brass and steel are type of metals that mostly use for moist area and also have luxury used cause of ability of shine .Steel definitely is for anti oxide ,mostly use in area that food and liquid such as acid ,milk ,soda,water are in contact .Brass most use for electric parts and decoration for ability of conductivity and shin .

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Look up a knife maker called Bench Made, the knife i recommend is the CQC7 its a tanto tip half serrated blade all low glare black folding with pocket clip. it has one of the hardest steel blades. You need to learn about steel hardness the harder the blade the sharper it can get and the harder the longer it will hold a edge. but hard steel can get brittle it can snap now as softer steel will bend and dull quick. the bench-made CQC7 goes for around $100 or that ball park...enjoy read some about the knife and think about what you want it for....my CQC7 can cut a coat hanger by pulling the serrate across the hanger!!

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil with Prime Quality Green Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords