Pre-painted Galvanized Steel Sheet Coil with Prime Quality and Best Price, Red Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

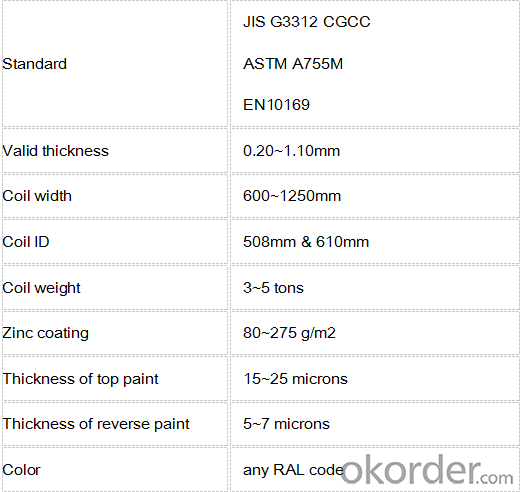

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do steel coils contribute to sustainable construction?

- Steel coils contribute to sustainable construction in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions and resist corrosion, leading to longer-lasting structures. This durability reduces the need for frequent repairs and replacements, thereby reducing waste and conserving resources. Secondly, steel is a recyclable material, meaning that at the end of a building's life cycle, the steel used in its construction can be easily and efficiently recycled. This reduces the demand for new steel production, which is energy-intensive and releases greenhouse gases. By using steel coils made from recycled steel, the construction industry can significantly reduce its environmental impact. Additionally, steel coils are versatile and can be shaped and formed into various structural components, allowing for efficient use of materials and minimizing waste. The lightweight nature of steel coils also makes transportation and handling more cost-effective and environmentally friendly. Furthermore, using steel coils in construction can contribute to energy efficiency. Steel has excellent thermal conductivity, which means it can effectively transfer and distribute heat, enabling better insulation and reducing energy consumption for heating and cooling. Overall, steel coils play a vital role in sustainable construction by promoting durability, recyclability, efficient material usage, and energy efficiency.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: How are steel coils inspected for impact resistance using impact testers?

- Steel coils are inspected for impact resistance using impact testers, which are specially designed machines used to assess the ability of the steel coils to withstand impacts. The process involves subjecting the steel coils to controlled impacts and measuring the extent of deformation or damage caused by the impact. Firstly, the steel coils are securely placed on the impact tester, ensuring that they are in the correct position and orientation. The impact tester is equipped with a striking element, such as a pendulum or a falling weight, which is designed to deliver a specific amount of force upon impact. The striking element is carefully aligned with the steel coil to ensure accurate and consistent testing. Once everything is set up, the impact tester is activated, and the striking element is released to impact the steel coil. The force of the impact is carefully controlled and measured to ensure consistency across multiple tests. The impact tester records various parameters during the impact, including the force applied and the duration of the impact. After the impact, the steel coil is carefully examined for any visible deformation or damage. This can include checking for dents, cracks, or any other signs of structural compromise. The extent of the deformation or damage is recorded and compared to predetermined acceptance criteria to determine whether the steel coil passes or fails the impact resistance test. Impact testers can be equipped with various sensors and cameras to capture additional data during the testing process. High-speed cameras can be used to record the impact in slow motion, allowing for a detailed analysis of the coil's behavior during the impact. Strain gauges can be attached to the steel coil to measure the strain and stress experienced during the impact. Overall, the use of impact testers provides a reliable and standardized method for inspecting the impact resistance of steel coils. By subjecting the coils to controlled impacts and carefully measuring the extent of deformation or damage, manufacturers can ensure that their steel coils meet the required impact resistance standards for various applications.

- Q: How are steel coils used in the production of storage racks?

- Steel coils are used in the production of storage racks by being uncoiled, cut, and shaped into the required dimensions and components of the racks. These steel coils provide the necessary strength and durability to support heavy loads and ensure the stability and longevity of the storage racks.

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- 1. okorder 2. Input (melting point 1008 steel) as the search string 3. Check the links; the third one showed the answer in an MSDS

- Q: I would like to know if steel is basically a very dense crystal, or if it is a different atomic structure

- Steel is made of billions, trillions of very small crystals. This is true of most metals. In order to see the crystal structure of steel, you usually need to cut a sample of it, grind and polish the cut face smooth, then etch the steel with a mixture of nitric acid and alcohol. Without polishing and etching the crystals aren't visible- it just looks like smooth solid metal. Also, in most cases the crystals are small enough that you need a microscope to see them clearly after etching.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: the comparison needed between other steel

- It's cheaper than alloyed steels.

- Q: What are the benefits of using steel coils in the manufacturing of pipes?

- Using steel coils in the manufacturing of pipes has several advantages: 1. Strength and durability: Steel is renowned for its strength and durability, making it an ideal material for pipes. By utilizing steel coils, pipes are provided with a solid foundation, enabling them to withstand high-pressure applications and resist damage from external factors such as impact or corrosion. This strength and durability increase the lifespan of the pipes, reducing the need for frequent replacements. 2. Customizability: Steel coils offer a high degree of flexibility in terms of customization and design. They can be easily formed into various pipe shapes and sizes, allowing manufacturers to produce pipes that meet specific project requirements. This flexibility also allows for the production of seamless pipes, which have superior structural integrity and a reduced risk of leakage. 3. Excellent thermal conductivity: Steel possesses excellent thermal conductivity, meaning it efficiently transfers heat or cold. This property is essential for pipes used in industries such as oil and gas, where temperature control is crucial. By utilizing steel coils, pipes can effectively handle extreme temperatures, preventing any damage to the pipes or the substances flowing through them. 4. Cost-effectiveness: Steel coils can be produced in large quantities, resulting in economies of scale and lower production costs. This cost-effectiveness benefits both manufacturers and consumers, as it helps keep the overall cost of pipes down. Additionally, the durability of steel pipes reduces the need for frequent repairs or replacements, resulting in long-term cost savings. 5. Enhanced corrosion resistance: Steel coils can be coated with protective layers to enhance their resistance to corrosion. This corrosion resistance is vital in applications where pipes come into contact with corrosive substances or are exposed to harsh environmental conditions. By utilizing steel coils with appropriate coatings, manufacturers can ensure that their pipes have a longer lifespan and maintain their structural integrity even under challenging circumstances. In conclusion, the utilization of steel coils in pipe manufacturing provides numerous benefits, including strength, customizability, thermal resistance, cost-effectiveness, and corrosion resistance. These advantages make steel coils the preferred choice for many industries that rely on durable and efficient piping systems.

- Q: How are steel coils used in the production of agricultural fencing?

- Steel coils are used in the production of agricultural fencing as they are transformed into wires that are woven, welded, or twisted to create durable and sturdy fences. These steel coils are typically made from high-quality steel, which ensures strength and longevity, making them ideal for withstanding the demands of agricultural environments.

Send your message to us

Pre-painted Galvanized Steel Sheet Coil with Prime Quality and Best Price, Red Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords