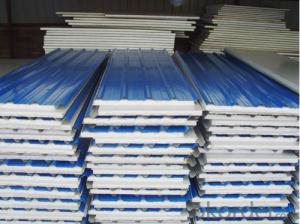

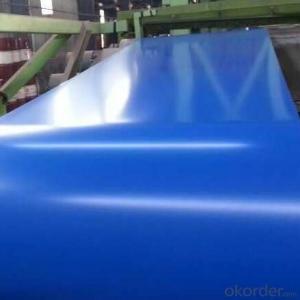

Pre-Painted Galvanized Steel Coil/Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prepainted steel coil

Specifications

1.Standard: ASTM,GB,JIS

2.Grade : DX51D+Z

3.Thickness: 0.18-1.5mm

4.Width:914-1250mm

5.Top paint:20mil,Black paint:7mil

6. Technical/Surface treatment: color coated/galvanized/galvalume

7..Useage: widely used in construction,home,appliance,decoration,wear resistant steel,etc.

Advantages:

1. more than 10 years experiences in steel b2usiness

2. good quality

3. competitive price

4. meet your needs via reprocessing

5. excellent service

6. short delivery time

Company :

CNBM is the specialized manufacturer of the prepainted steel coil ,

including the PPGI and PPGL . And our products have exported to Korea , Southeast Asia ,

Russia , Middle East ,South America ,South Africa ,Northern Europe and do on .

Product :

Commodity : | Prepainted steel coil /PPGI /PPGL |

Materials Grade: | SGCC ,CGCC ,DX51D+Z ,SGLCC |

Thickness : | 0.17-1.2mm |

Width : | 914mm,1219mm,1000mm,1220mm,1250mm ( can cut to strip above 30mm width ) |

Zinc coating : | 60-275g/sqm |

Surface Structure: | Galvanized Or Aluzinc |

Color : | RAL No. or Sample color |

Painting : | Top : 5micron primer +15-20microns polyester |

Coil Weight : | 2-6mts |

Payment term : | TT ,L/C AT SIGHT , USANCE L/C ,D/P |

Shipment : | 20 feet container or bulk ship |

Remark : | We accept the third-party inspection ,such as SGS , |

- Q: What is the process of slitting steel coils into narrower strips?

- The process of slitting steel coils into narrower strips involves feeding a large steel coil through a slitting machine. The machine uses circular blades or rotary knives to make precise cuts along the length of the coil, creating narrower strips. These strips are then rewound onto separate reels or spools, ready for further processing or shipment.

- Q: Can steel coils be coated with luminescent materials?

- Yes, steel coils can be coated with luminescent materials.

- Q: I am wondering if i can use my western guitar as a kind of steel-guitar, read something about it on Wikipedia.

- If you decide to get a true pedal steel, plan on spending some big money. Look on eBay for a Carter Starter. It will be the best guitar to start on...and not outgrow too fast.

- Q: What are the challenges in coil blanking for high-strength steel?

- Coil blanking for high-strength steel poses several challenges due to the unique properties of this material. One of the main challenges is the high tensile strength of the steel, which makes it more difficult to cut and blank compared to conventional steel grades. The high-strength steel is typically harder and less malleable, leading to increased tool wear and higher cutting forces. This requires the use of specialized cutting tools that are capable of withstanding these extreme conditions. Additionally, the increased cutting forces can lead to more vibration, which may affect the accuracy and quality of the blanks. Another challenge is the spring-back effect that high-strength steel exhibits after cutting. This means that the material tends to revert to its original shape, making it difficult to achieve precise dimensions and tolerances in the blanks. This issue requires careful consideration and adjustment of the cutting parameters to minimize the spring-back effect. Moreover, high-strength steel often has a higher carbon content, which can result in increased work hardening during the blanking process. Work hardening causes the material to become even harder and more brittle, making it more prone to cracks and fractures. To overcome this challenge, proper lubrication and cooling techniques are crucial to reduce heat buildup and minimize the risk of cracking. Furthermore, the increased strength of the steel may also affect the overall production efficiency. The higher cutting forces and tool wear mean that the cutting speeds may need to be reduced, leading to longer processing times. This can impact the productivity and throughput of the coil blanking process, requiring careful optimization and planning. In summary, the challenges in coil blanking for high-strength steel include increased cutting forces, tool wear, spring-back effect, work hardening, and reduced production efficiency. Overcoming these challenges requires specialized cutting tools, precise cutting parameters, proper lubrication and cooling techniques, and careful optimization of the production process.

- Q: What are the different steel coil specifications?

- There are several different steel coil specifications available, including dimensions, thickness, width, and weight. These specifications vary depending on the specific application and industry requirements. Additionally, steel coils can be classified based on their surface finish, such as hot-rolled, cold-rolled, or galvanized.

- Q: What are the common coil lengths available for steel coils?

- The steel coil lengths offered in the industry and specific requirements are subject to variation. Nonetheless, several standard coil lengths are extensively employed in different applications. These encompass coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths find extensive use in construction, manufacturing, and automotive sectors, where steel coils serve diverse purposes. It is worth mentioning that coil lengths can also be tailored to meet specific project requirements or customer preferences.

- Q: What are the common applications of galvanized steel coils?

- Galvanized steel coils are commonly used in various applications such as construction, automotive manufacturing, electrical appliances, and infrastructure projects. They are used for manufacturing roofing sheets, wall panels, pipes, gutters, and various structural components due to their corrosion resistance and durability. Additionally, galvanized steel coils are widely used in the production of automotive parts, such as body panels, frames, and chassis, as they provide excellent strength and protection against rust.

- Q: Would the Ruger Sr22 pistol or the SW MP 15-22 be any good for the steel challenge?

- Steel plates are very difficult for a .22lr

- Q: How are steel coils inspected?

- Steel coils are inspected through a combination of visual examination, dimensional measurement, and non-destructive testing methods such as ultrasonic testing or magnetic particle inspection. These inspections help identify any surface defects, cracks, or abnormalities in the coils to ensure they meet quality standards and specifications.

- Q: How are steel coils used in the manufacturing of airbags?

- Steel coils are used in the manufacturing of airbags to provide structural support and stability. These coils are typically incorporated into the airbag module, helping to maintain its shape and ensure proper deployment in the event of a collision.

Send your message to us

Pre-Painted Galvanized Steel Coil/Prime Quality Prepainted Galvanized Steel Coil for Roofing Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords