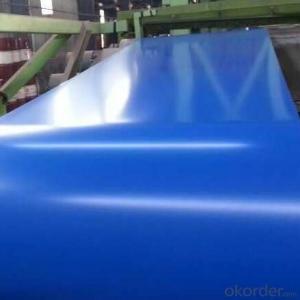

Prepainted Galvanized/Aluzing Steel coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Model NO.:G550, FULL HARD, SGHC

Type:Steel Coil

Standard:ASTM, GB, JIS

Certification:ISO, SGS, BV

Surface Treatment:Coated

Technique:Hot Rolled

Special Use:High-strength Steel Plate

Base Metal:Galvanized or Galvalume Steel

Width:914/1000/1200/1219/1220/1250mm

Thickness:0.16-1.2mm

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

Top Side Painting:15-25 Micron

Back Side Painting:5-8 Micron

Colour:Ral Standard or According to Customers′ Requirment

Coil Weight:3-6 Mt

Coil ID:508/610 Mm

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Packing

Standard:0.135-1.2MM

Origin:China, Shandong

HS Code:72107000

Production Capacity:180000mt

Product Description:

1. Standard: AISI, ASTM, BS, DIN, GB, JIS, ASTM, JIS, GB

2. Steel Grade: DX51D, SGCC, SGCH, SPCC, SPCD, DC01, ST12, ST13, Q195, 08AL

3. Thickness: 0.13-0.5mm

4. Width: 600-1250mm

5. Length: Up to The Thickness or as require

6. Spangle: Zero, Mini, Regular, Big, Skin Pass

7. Audited Certificates: BV, SGS, ISO, CIQ

8. Zinc Coating: 40g-200g

9. Surface: Chromated, dry/oiled, Cr3 treated anti-finger

10. Package: Standard exporting package (or as required)

11. ID: 508/610mm

Specification:

| commodity | Color Coated Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Base metal | galvanized, galvalume, cold rolled steel |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness) |

| Width | 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

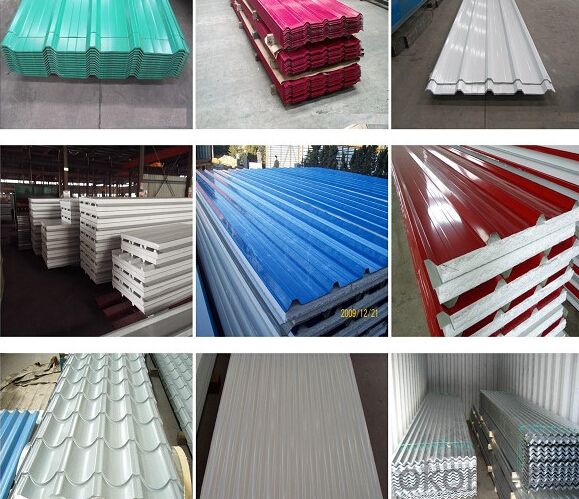

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

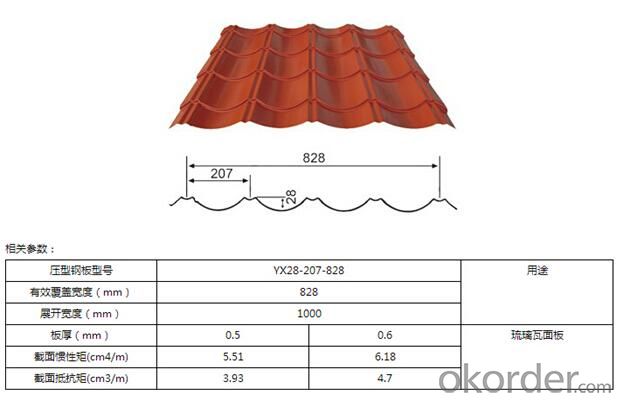

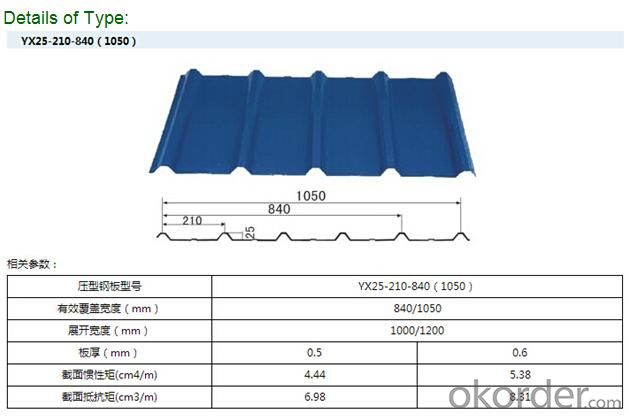

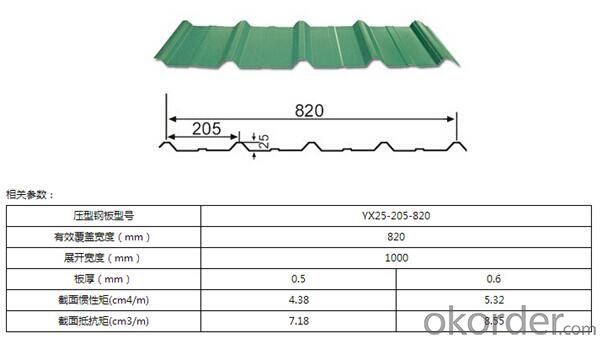

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: Well the other day i told my friend that when you put a compass near steel it will screw up and he said only magnets do that then i showed him and it worked then he said: that'ss because steel has its own magnet in it coz it builds up static electricity is that correct what he said? thanks

- No. Steel does not build up static electricity by itself. Also, magnetic fields are made by moving electricity, not static electicity. The steel conducts magnetism, so it changes the earth's magnetic field near itself by conducting the field through itself. The larger effect is a magnet near a piece of steel: the compass has a magnet, and when you place it near a ferromagnetic material, it attracts. Try putting a refridgerator magnet against the fridge - it sticks because it attracts.

- Q: How do the sandpaper grits compare with different coarse levels of steel wool? For example, I'm finishing a homemade entertainment center, and using a tinted polyurethane, and it says to use 000 grade steel wool, but mine is #3, could I use some sanpaper instead, and what grit?

- Steel wool and wax is for the final buff after the finish coat. Sanding will scratch the finish and should only be done before the finish coat. Steel wool and wax have been used as the final finish to remove rough areas and buff the finish for a long time.

- Q: Me and my cousin have been arguing about this. I said that superman is made out of steel, but he says that people just call him the man of steel because he's hard like steel. Does he have steel in his body?

- Superman okorder /

- Q: What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, cutting, shearing, and edge rolling. Slitting involves cutting the coil into narrower strips, while cutting involves separating the coil into smaller sections. Shearing is a process of cutting the edges of the coil to remove any irregularities or defects. Edge rolling is a method that involves rolling the edges of the coil to create a smoother and more uniform finish.

- Q: How do steel coils contribute to energy efficiency in transportation?

- There are several ways in which steel coils help improve energy efficiency in transportation. To begin with, steel coils are lightweight and have a high strength-to-weight ratio. This means that they require less steel material to carry the same load compared to other materials like wood or concrete. As a result, the overall weight of the transport vehicle is reduced, leading to lower fuel consumption and emissions. Furthermore, steel coils are extremely durable and can withstand harsh transportation conditions. They are highly resistant to corrosion, impact, and fatigue, ensuring a longer lifespan for the transport vehicle. This durability reduces the need for frequent repairs or replacements, resulting in reduced energy consumption and material waste. Moreover, steel coils are easily handled and transported. Due to their compact and standardized size, they can be effortlessly loaded and unloaded from trucks, trains, or ships. This efficiency in handling reduces the time and energy required for loading and unloading operations, ultimately increasing overall transportation efficiency. Additionally, steel coils can be efficiently stacked and stored, maximizing the utilization of available space in transport vehicles. This reduces the number of trips needed to transport the same amount of goods, resulting in less energy consumption and lower transportation costs. Lastly, steel is a highly recyclable material. At the end of their life cycle, steel coils can be easily recycled and used to produce new steel products. This reduces the demand for raw materials and the energy required for manufacturing new products, thereby contributing to overall energy efficiency in transportation. In conclusion, steel coils play a crucial role in enhancing energy efficiency in transportation. Their lightweight, durable, easy-to-handle, and recyclable nature leads to decreased fuel consumption, lower emissions, reduced maintenance needs, efficient use of space, and minimized material waste. All of these factors contribute to a more sustainable and energy-efficient transportation system.

- Q: i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Comp is right- Lowe's sold you mild steel. Good for a lot of things, but holding an edge isn't one. If you want to make some sort of edged tool, try something like Smokey Mountain Knife Works or another online vendor. They have better blades, even some Damascus blades which will hold an edge much better. If you want to make your own blades, you'll need to start with better steel and build your own forge. I made one from a brake drum and a vacuum with a dimmer switch. You'll also need an anvil, something that may be a bit tough to locate. A couple of hammers and you can start forging blades. For something simpler, locate a place where you can learn blacksmithing and forging. Some art classes teach this at a community college, but not many. Check the site below and see if you can go with ABANA. ... Good luck!!

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. This coating provides several benefits such as increased corrosion resistance, improved heat resistance, and enhanced durability. Additionally, ceramic coating can also provide an aesthetic appeal to the steel coils.

- Q: Is there alloys in low carbon steel or non

- Stainless Steels are alloys that are made up of iron and generally contain around 11.5% chromium. For obtaining special properties, nickel, carbon, chromium, and other elements can be added to it. There are four types of Steel : Carbon Steel Alloy Steel Stainless Steel Tool Steel From kitchen utensils to cutlery, sinks to machine drums, as well as microwave oven liners mainly, use Stainless Steel. One can find different types of products such as Stainless Steel Tube Fittings, Pipe Fittings, Flanges, pipes, Tubes, Fasteners, Sheets, Rods, Bars and so forth are used in different industries. List of typical applications of these Stainless Steel products include: Oil and gas equipments Offshore technology Seawater desalination plants Chemical industry Bridges Storage tanks Medical Industry Civil Engineering Pressure vessels, reactor tanks, and heat exchangers Rotors, impellers and shafts Power plants Petrochemical Shipbuilding industry

- Q: So...I'm learning about how steel is made and I'm wondering if there is a more environmentally friendy method. I view it as unfriendly b/c of the oxygen that is injected when the steel is in the blast furnace or electric arc furnace. This oxygen bonds w/ the carbon to produce CO and CO2. THis is necessary to reduce the amount of carbon content to produce harder steels. So what other methods are there that can be used w/o having to end up w/ co and co2? thanks

- From what I understand of it, US steel is better as the steel is more recycled than Canadian, so a lot of that oxygen / CO2 has already taken place compared to working from ore. The second reason US steel is environmentally ahead of Canadian is that US tends to use Electric Arc, while Canadian uses Basic Oxygen, Basic Oxygen uses more energy than electric arc, and I think it also uses more oxygen, but I would suspect that oxygen that it uses is 'waste oxygen' and not converted into Co2 because the Co2 process is limited by the carbon, and steel only has so much carbon.

- Q: ...particularly for jewelry?

- Surgical stainless steel is a variation of steel usually consisting of an alloy of chromium (12–20%), molybdenum (0.2–3%), and sometimes nickel (8–12%). The chromium gives the metal its scratch-resistance and corrosion resistance. The nickel provides a smooth and polished finish. The molybdenum gives greater hardness, and helps maintaining a cutting edge. In metallurgy, stainless steel (inox) is defined as a ferrous alloy with a minimum of 10% chromium content.[1] The name originates from the fact that stainless steel does not stain, corrode or rust as easily as ordinary steel. This material is also called corrosion resistant steel when it is not detailed exactly to its alloy type and grade, particularly in the aviation industry

Send your message to us

Prepainted Galvanized/Aluzing Steel coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords