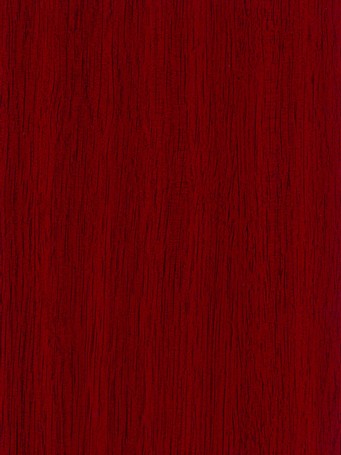

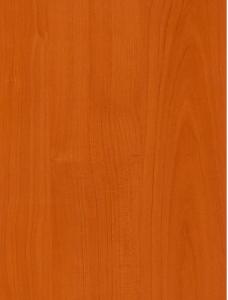

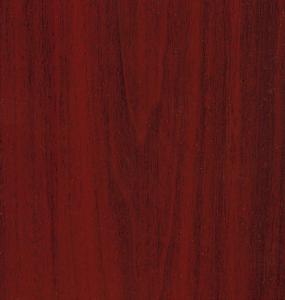

Pre-painted Galvanized Steel Coil-EN10169-WOODEN7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: Can steel coils be used in the production of aerospace components?

- Yes, steel coils can be used in the production of aerospace components. Steel coils are commonly used in the manufacturing of various aerospace components such as structural frames, fasteners, landing gear, and engine parts. The high strength, durability, and versatility of steel make it a suitable material for these critical components in the aerospace industry.

- Q: What are the different types of edge conditions in steel coils?

- There are several types of edge conditions in steel coils, including mill edge, slit edge, rounded edge, deburred edge, and trimmed edge.

- Q: How are steel coils protected during storage and transportation?

- Steel coils are protected during storage and transportation through various measures. These include wrapping them with protective materials such as plastic or paper, using wooden or metal cradles to provide support and prevent damage, securing them with steel bands or straps to prevent movement, and storing them in well-ventilated and dry areas to prevent corrosion.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as the type of steel, the thickness and size of the coils, and market conditions. It is best to contact suppliers or check current market prices for accurate cost information.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- Casting is a process of forming a part just like forging or rolling are also processes of forming steel. Cast steel can be any grade of steel poured into a sand mold to form a part like a water pump housing in your car. To be classified as steel, the mixture usually contains less than 2% carbon. Cast iron is a mixture that generally contains more than 2% carbon. It also can be poured into a sand mold. There are many grades of iron. Many metals can be cast into shapes like the air intake plenum on your car is probably cast aluminum. Bronze statues are made by pouring molten bronze into a mold. The process used to create a part has an effect of that part's mechanical properties. A casting is weaker than a forging but certain parts cannot be formed by forging. The large diameter rolls used in steel mills to roll steel into thinner plates or sheets is a hot rolled steel that has probably been forged into shape then machined into the final diameter. Some rolls are fabricated from hot rolled steel plates into shape. This allows the ability to add internal cooling paths to keep the roll from overheating.

- Q: Can steel coils be perforated?

- Yes, steel coils can be perforated. Perforation is the process of creating small holes or punctures in a material, and steel coils can undergo this process to achieve specific purposes such as enhancing ventilation, improving drainage, or creating decorative patterns.

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials. The phosphorescent coating can be applied to the surface of the steel coils, allowing them to emit a glow in the dark or low-light conditions.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using cranes or heavy machinery. The coils are lifted onto the ship using hooks or clamps, and secured in place to prevent movement during transportation. Once the ship reaches its destination, the coils are then carefully lifted off the ship and transferred to trucks or other modes of transportation for further distribution.

- Q: What are the common coil thickness tolerances?

- The common coil thickness tolerances can vary depending on the specific industry and application. However, typical tolerances for coil thickness range from +/- 0.001 inches to +/- 0.005 inches.

- Q: Can steel coils be coated with barcodes?

- Yes, steel coils can be coated with barcodes.

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN7

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords