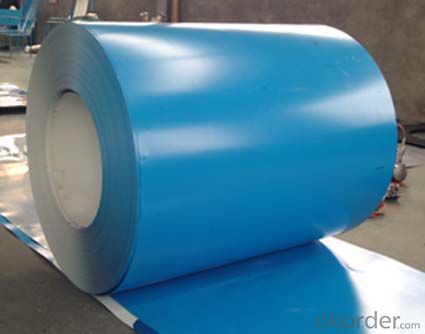

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after liquid dope with several layers of color

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• Superior workability

• High strength

• Good visual effect

• Good capable of decoration

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

5.FAQ

1. What’s the application of this product?

surface sheet of balcony, frame of window, etc.

- Q: What are the different coil leveling methods used for steel coils?

- Steel coils can be leveled using various methods, each with its own advantages and limitations. Here are some commonly used methods: 1. Roller Leveling: Coils pass through rollers that apply pressure to flatten and level them. This method is effective in reducing coil crown or center buckle and eliminating coil memory. However, it may not be suitable for coils with severe shape defects or variations. 2. Stretch Leveling: Coils are stretched to remove shape defects. Gripper heads hold the edges of the coil while it is stretched. Stretch leveling is particularly effective in correcting crossbow and edge wave defects. However, it may cause elongation and yield loss in the material. 3. Temper Pass: Coils go through temper mill stands, where tension and compression forces are applied. Temper pass leveling improves flatness and removes coil memory. It is commonly used for thinner gauge steel coils but may not be suitable for thicker coils. 4. Corrective Leveling: This method is used for coils with severe shape defects. Skilled operators selectively remove material from specific areas of the coil to correct the shape. Corrective leveling effectively eliminates shape defects and improves flatness but requires significant labor. 5. Tension Leveling: Coils undergo tension forces while passing through pinch rolls. Tension leveling removes coil memory and improves flatness, especially for coils with edge wave defects. However, it may cause elongation and yield loss in the material. These are just a few of the coil leveling methods used for steel coils. The choice of method depends on specific requirements and desired flatness results. Considerations such as material thickness, shape defects, and production capacity are important in selecting the appropriate leveling method.

- Q: What are the different types of steel coil storage racks?

- There are several different types of steel coil storage racks, including coil cradles, coil saddles, coil blocks, and coil storage bins. Each type is designed to safely and efficiently store steel coils based on their size, weight, and specific requirements.

- Q: I am in the US and looking for a price on wide flange steel. I need a price of one W10x30 and 20 feet long.

- The price of steel is increasing daily, so an exact answer is rough. A W10x30 is a fairly common shape and shouldn't be too hard to find. For a very rough ballpark number, say $700/ton (installed price), the piece you require should be in the range of about $250.00 or less as I assume you'll be doing the installing. Please don't take this as the gospel, however. Price varies on location, stock, and availability. Open the phone book and contact your local steel supplier. Because the piece you require is fairly short, you might get lucky and find someone who has a waste piece that length that they will give you a good deal on. --------------------------------------... I just checked the AISC web site to verify the number I quoted above and they posted an article stating that the average mill price had just increased to over $1000/ton in May. The best advice I can provide at this point is to buy the W10 now and don't wait any longer.

- Q: What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q: What are the challenges faced during steel coil processing?

- There are several challenges that can be encountered during steel coil processing. One of the main challenges is ensuring proper handling of the steel coils. Steel coils are heavy and can weigh several tons, so it is crucial to have the correct equipment and procedures in place to safely move and manipulate the coils. This includes using cranes, forklifts, or other lifting devices that are strong enough to handle the weight and size of the coils. Another challenge is maintaining the integrity of the steel coils during processing. Steel coils are susceptible to damage from scratches, dents, or other forms of physical deformation. It is important to have proper storage and handling procedures in place to minimize the risk of damage. Additionally, care must be taken during cutting, slitting, or other processing operations to ensure that the coils are not damaged or compromised. Quality control is another significant challenge in steel coil processing. It is essential to consistently produce coils that meet the required specifications, such as thickness, width, and surface quality. This requires meticulous inspection and monitoring throughout the entire processing chain, from receiving the raw material to the final product. Any deviations from the desired specifications can result in rejected coils or customer dissatisfaction. Efficiency and productivity are also challenges in steel coil processing. The processing operations need to be optimized to minimize waste, reduce downtime, and maximize throughput. This can involve implementing automation, improving production planning, and streamlining the workflow. Additionally, balancing the production speed with maintaining quality standards is crucial to ensure efficient and productive processing. Lastly, safety is a significant challenge in steel coil processing. The nature of the equipment and processes involved poses various risks to workers, including the potential for accidents, injuries, or exposure to harmful substances. It is vital to have proper safety protocols in place, provide adequate training to employees, and regularly inspect and maintain the equipment to ensure a safe working environment. In summary, the challenges faced during steel coil processing include handling the heavy coils, maintaining their integrity, ensuring quality control, optimizing efficiency and productivity, and ensuring a safe working environment. By addressing these challenges, steel coil processors can achieve smooth operations and deliver high-quality products to their customers.

- Q: What are the safety standards for steel coil manufacturing?

- The safety standards for steel coil manufacturing include proper handling and storage, regular equipment maintenance, adherence to operational procedures, personal protective equipment usage, and comprehensive training programs for employees. Additionally, safety protocols related to transportation and loading/unloading processes must be followed to ensure a safe working environment.

- Q: Which movie is better and why?I say Man of Steel!

- Pretty hard, I feel like Captain America The First Avenger had less flaws, but I more enjoyed Man Of Steel. I don't know why people didn't like how Cap first started out with advertising/singing and all that. I actually applauded Marvel for having the guts to stay true to the character's origin. Henry Cavill has the best look for Superman in my opinion, but I do agree with the critics that say he doesn't reflect the character's personality accurately. He's too dark, reminds me of Batman, but if he talked less. I disagree with the Superman killing conflict. True, the character is not a killer, but that's exactly why they wrote that in. Internal character conflict. Put him at war with himself. Plus, it gave the grand opportunity to give Doomsday his new origin, which I kinda liked. In the end, I'll say Man Of Steel, they really dove deep into that movie, it was well written and had a great plot. I loved seeing and learning more of Krypton. Crazy how I'm not even a huge Superman fan????

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems primarily for their strength and durability. They form the core structure of various components such as heat exchangers, condenser coils, and evaporator coils. The steel coils provide stability and support, ensuring the longevity and efficiency of HVAC systems by withstanding high temperatures, pressure, and constant use.

- Q: How are steel coils used in the manufacturing of chassis frames?

- Steel coils are used in the manufacturing of chassis frames by being processed and formed into specific shapes and dimensions. The coils are first uncoiled and then passed through various machines to cut, bend, and weld them into the desired frame structure. This process ensures that the chassis frame is strong, durable, and able to withstand the demands of a vehicle's weight and functionality.

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders can vary depending on various factors such as the quantity and specifications of the coils, current market conditions, and the supplier's production capacity. However, lead times commonly range from a few weeks to a couple of months. It is always best to confirm with the specific supplier for accurate and up-to-date lead time information.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price in Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords