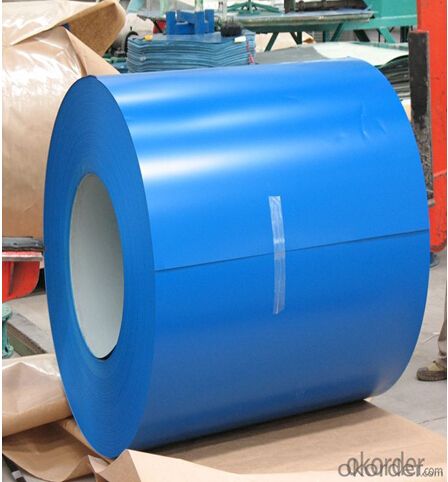

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Blue color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted GI/GL Steel Coil Images

4.Pre-painted GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wrapped around an iron core, creating an electromagnetic field when electricity flows through them. This electromagnetic field generates the necessary force that allows the motor to convert electrical energy into mechanical energy, enabling the motor to function and perform various tasks.

- Q: Do any tour players use steel shafted woods? And are there any real advantages to having steel shafted woods? I have only played with one person to use steel shafted woods, he tells me thats because he cant hit it straight with graphite, however he is a very short hitter.

- Graphite shafts are generally better for the amateur golfer. Graphite shafts are more forgiving than stell shafts. With graphite shafts, it is easier to get the ball in the air, and keep your ball trajectory always with good height. For SOME above average golfers and tour professionals, steel shafted woods find their way into their bags. This is because steel shafts have the ability of being more precise in terms of direction. However, to hit steel shafted woods, you need a lot of power and a slightly faster than normal tempo. Point is, if your a golfer that plays this sport for the leisure, or don't want to be stressed, take the graphite shafts. But if you're a single-digit handicapper, and feel you're physically fit ALL THE TIME, then go ahead and try the steel shafts.

- Q: How are steel coils protected during storage and transportation?

- Steel coils are protected during storage and transportation through various measures. Firstly, they are typically wrapped with a layer of protective material such as plastic or paper to shield them from moisture, dust, and other contaminants. Additionally, steel coils are often stored in a controlled environment, such as a warehouse, to prevent exposure to extreme temperatures and weather conditions. During transportation, they are secured using specialized equipment such as steel coil racks, which prevent movement and minimize the risk of damage. These protective measures ensure the integrity and quality of steel coils throughout their storage and transportation processes.

- Q: What are the environmental considerations associated with steel coil production?

- The environmental considerations associated with steel coil production include the extraction of raw materials, such as iron ore and coal, which can lead to habitat destruction and air/water pollution. The manufacturing process involves energy-intensive operations and emissions of greenhouse gases, contributing to climate change. Waste generated during production, such as slag and dust, can also have negative impacts on the environment if not properly managed. Additionally, the transportation of steel coils over long distances can result in carbon emissions and increase the overall environmental footprint of the product.

- Q: Edward Humphrey wants to know... Can I use steel roofing on an older house?

- ed like others have said yes you can and its relatively simple to do. ? is it steal you want or would to plastic they call it work. we've done several around here in central Illinois and we've done both. as far as putting boards under the metal we've only done that on one, usally you start at a bottom corner, work your way across the roof and up just as you do shingles, remember though unlike shingles these don't have any sealing strips, so under each overlap before putting the piece on you need to put a sealer bead on. the tubes from your local lumber yard work just fine. just remember dont hurry yourself into making mistakes and forgetting anything. i don't know if you have helpers but generally you can hire a high school kid to help put this on. it isn't really that hard.use whats called a barn screw to hold it onto your existing roof,( they are color coated, and have rubber gaskets) so no leaks where fastened unlike nails.

- Q: How are steel coils used in the production of metal storage systems?

- Steel coils are used in the production of metal storage systems as they can be cut and shaped into various components, such as beams, frames, and shelves. These coils provide the necessary strength and durability required for constructing robust and reliable storage systems.

- Q: What are the common coil thickness tolerances?

- The common coil thickness tolerances can vary depending on the specific industry and application. However, in general, common coil thickness tolerances range from +/- 0.001 to +/- 0.010 inches.

- Q: Can steel coils be used in marine environments?

- Yes, steel coils can be used in marine environments. However, it is essential to ensure that the steel coils are properly protected against corrosion, as the saltwater and high humidity in marine environments can accelerate the process of rusting. Various coatings and treatments can be applied to steel coils to enhance their resistance to corrosion and make them suitable for use in marine applications.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- Steel coil is a kind of steel plate, also known as coil.The coil, like toilet paper, can roll into a barrel. (describe not very appropriate)When the coil is used, it is necessary to use the Kaiping machine to expand into a flat plate.

- Q: How are steel coils distributed globally?

- Steel coils are distributed globally through a well-established supply chain network. Manufacturers typically ship steel coils to various locations worldwide through ocean freight or rail transportation. These coils are then distributed to customers, including construction companies, automotive manufacturers, and other industries, through local distributors or directly from steel service centers. Additionally, international trade and partnerships play a significant role in the global distribution of steel coils, ensuring a steady supply to meet market demands.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Blue color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords