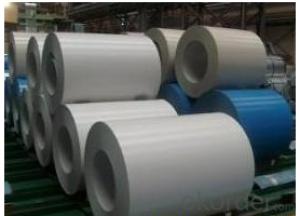

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,degrease , chemical treatment and liquid dope with several layers of color

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

• Superior workability

• Good visual effect

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Available Painting OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 5+20microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

5.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

- Q: What is the minimum thickness of a steel coil?

- The specific grade and type of steel being used, along with the manufacturing process, can cause the minimum thickness of a steel coil to vary. Generally, a steel coil is typically about 0.001 inches (0.0254 millimeters) thick. It is worth mentioning that this value is a general rule and may change depending on the industry's or application's specific requirements and standards.

- Q: I just bought a used Taurus 85 stainless 38 spl revolver, it's about 25 years old but looks like new. This is my first stainless steel gun. I'm wondering if there's any special things I need to be aware of or cleaning methods? I'm also wondering if stainless steel could rust? in theory stainless means it cannot get stained or rusty. I have a chrome bore AK, cleaning is always super easy, wondering of cleaning a SS revolver would be the same.

- Stainless steel does not rust. But your Stainless Barrel is not true stainless steel. True stainless steel is a mix of steel and chrome, and the chrome has a certaion percentage of the overal weight.. But a Stainless barrel does not contain enough chrome to be true stainless, so it can rust.

- Q: hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Primary Steel Making first Iron ore Coke Lime stone are mined and then took to the steel plant and put in the top off a blast furnace and sinks down to the bottom off the blast furnace and turns into molten iron. Once this process has been done it is then transferred to a BOS (Basic Oxygen Steel Making) this is then poured from a ladle into the BOS and a Lance is inserted into the BOS and pure oxygen is blown into the BOS for about 30 min and turns into steel.

- Q: This is my first time buying new strings for my violin and I’ve narrowed it down to two choice based on reviews and cost. The only difference I can see between the strings is that one has a solid steel core and the other has a synthetic core. What are the pros and cons of each type of core?

- Steel okorder /

- Q: What are the main factors that affect the formability of steel coils?

- The main factors that affect the formability of steel coils include the composition and microstructure of the steel, the thickness and width of the coils, the presence of any impurities or defects in the material, the temperature and speed of the forming process, and the type of equipment and tooling used for forming.

- Q: I bought a Remington 870 super mag last fall and wanted to to switch to non-tox steel loads. The gun came with a modified rem choke. I know that not all chokes are qualified to handle steel. It doesn't say anywhere on the choke no steel I was just wondering if anyone out there knew for sure that those chokes that the guns come with won't get damaged be steel.

- No problem. With steel shot you would use one choke size LARGER. If you want a full choke type pattern ( 70 % in a 30 inch circle at 30 yards ) you use a modified choke. if you want a modified pattern use the improved cylinder. Don't use the full or extra full. This is because when using lead shot it deforms, and fits through the choke, steel shot does not deform, it remains rigid. The first indication of a problem will be a slight bulge in the barrel right behind the choke. Check that once in a while, if you ever have that problem, it is not drastic if caught early. Today's modern shotguns all have been set up for steel shot. The old ones such as Belgium Brownings, are a no go. Funny thing, when we first began importing steel shot, I asked a Browning Tech guy if he thought I could fire steel out of my Belgium Browning. He said not a good idea, however, if you have the Citori or other Japanese made Brownings, no problem. Hummm, my expensive Brownings, no, but Japanese made OK, this is because the Japanese steel was higher quality. Geeeze. I was shocked.

- Q: How are steel coils used in the manufacturing of automotive accessories?

- Steel coils are used in the manufacturing of automotive accessories as they are processed and shaped into various components such as brackets, frames, and supports. These coils are typically cut, molded, and stamped into specific shapes before being assembled into the final product, adding strength and durability to the accessories.

- Q: Hi there! I just purchased two cookie sheets labeled as non-stick 100% carbon steel. I've never heard of carbon steel before, and I'm trying to be careful about not using certain products that are harmful to health such as aluminum and Teflon. Is this a safe metal choice for baking?

- 100 carbon steel baking sheet safe

- Q: Personally, I like Steel Cage matches to end in pinfalls. One of the biggest selling points of a Cage match is that it is to keep the competitors in and keep others out; essentially ensuring that it's a 1 on 1 match. As a result, I believe that pinfalls or submissions are important - but I know there's a lot of people that believe cage matches should only end in escape. What do you think??

- I don't really care either way. The only way I don't like it to end is when the door is opened and the person just walks out. That really isn't hard to win it like that. For last night I was hoping before the match that Bryan would win by escaping the cage. It fit his character, being a coward champ.

- Q: What are the different types of steel coil edge treatments?

- In the manufacturing and processing of steel coils, various steel coil edge treatments are employed. These treatments serve to improve edge quality, protect against damage, and facilitate the handling and processing of the coils. Some of the prevalent types of steel coil edge treatments are as follows: 1. Mill Edge: The steel mill provides this standard edge treatment, which is the raw edge of the steel coil generated during the hot rolling process. The mill edge is typically sharp and may exhibit some irregularities. 2. Slit Edge: Slit edge treatment involves slitting the coil to the desired width and subsequently processing the edges to eliminate any burrs or unevenness. Compared to mill edge coils, slit edge coils have smoother edges. 3. Deburred Edge: The deburring process removes any sharp or rough edges from the coil using specialized equipment or techniques, resulting in a smoother and safer edge. Deburred edges find common use in applications where safety and handling are of utmost importance. 4. Rounded Edge: Rounded edge treatment entails rounding the edges of the coil to minimize the risk of damage during handling and processing. This treatment is frequently employed in applications where the coil must be uncoiled or fed into machinery without incurring any damage. 5. Beveled Edge: Beveling involves chamfering or cutting the edges of the coil at an angle. Beveled edges are utilized in applications where easy insertion, joining, or welding of the coil is required. The beveling process also enhances the strength and durability of the edge. 6. Sheared Edge: Shearing is a cutting process that employs high-pressure blades or scissors to cut the coil to the desired width. Sheared edge treatment yields a clean and straight edge, devoid of burrs or irregularities. It is commonly employed in applications that necessitate precise dimensions and a smooth edge. These are merely a few examples of the various steel coil edge treatments commonly employed in the industry. The selection of edge treatment depends on specific application requirements, such as handling, processing, safety, and aesthetics.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color White

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords