Aluminum Foil Candle Insulated Aluminum Panel Insulated Ductwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

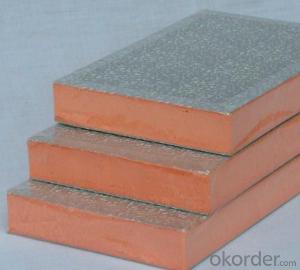

Pre-Insulated Aluminum Panel Insulated Ductwork

1.Structure of Pre-Insulated Aluminum Panel Insulated Ductwork

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Pre-Insulated Aluminum Panel Insulated Ductwork:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

3. Pre-Insulated Aluminum Panel Insulated Ductwork Images

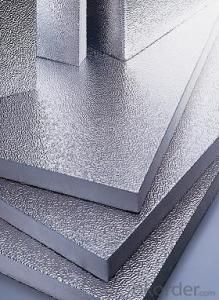

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

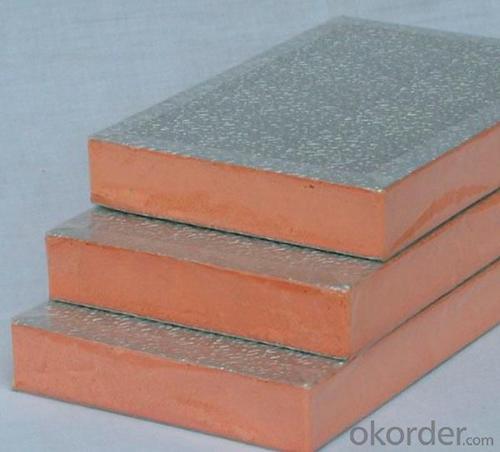

4. Pre-Insulated Aluminum Panel Insulated Ductwork Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q: i want to bake some dinner rolls but i cant find a baking sheet! HELP

- ya get nuts and bread and eat it and the same time and u cane add whetever pear is hehehehehe!!!!!!!!!! joking no i dont havbe one

- Q: k so this is my first time making a home made water bongim using a socket wrench head as my quot;bowlquot; i guess u would call itthe place where i would pack my herbsok so do i need to add a filter to that or is that the filteror does the water count as the filter? i know some ppl put like aluminumwhy do they do that? also how much water do i add in the water bottle and how often do i change itthanks lt;333

- This Site Might Help YouRE: What are the advantages/disadvantages of aluminum vs fiberglass bass boat? I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it upThe G3 is aluminumWhat are the pros and cons?

- Q: If I'm frying some steak in a frying pan, can I use the little amount of fat and oil left and make it into a gravy? or does it have to come from oven baked turkey?

- Check the label on the worsted weight yarn- it will tell you the recommended needles to use, and the suggested gaugeIf the needle size and gauge are the same in the pattern, you should be all setIf they're different, you need to figure out what needle size you need to use to get the gauge that is listed in the pattern.

- Q: any ideas, my son has to make a airplane out of household things?

- The key here is that YOUR SON has to make an airplane - not youThis is about being creativeIf you're helping him, he's not exercising his creativityCut him loose in the kitchenThink aluminum foil and aluminum cake pansMaybe steer him towards those items and then let him come up with the rest.

- Q: I am looking to add text onto metalDoes anyone know if it is possible to do with a normal print and what steps are involved? Thanks!

- maybe s/he doesn't like the darki heard they can tell the difference when you're further along like you arecongrats and good luck with everything!

- Q: does anyone have a good recipe for Embutido (filipino meatloaf)?

- Ingredients : · 1 lbground pork · 1/2 cup finely chopped carrots · 1 cup (6 slices) finely chopped (sweet or cooked) ham · 3 tbspminced green bell pepper · 3 tbspminced red bell pepper · 1/3 cup sweet pickle relish · 1/4 cup raisins · 3 whole eggs · 1/2 cup grated cheddar cheese · dash of liquid seasoning · salt pepper, to taste · 1 tbspcornstarch · slices (wedges) of hard-cooked eggs (see recipe) · slices (wedges) of Vienna sausage · aluminum foil, 10 x 12 sizes (Cooking Conversion Chart) Cooking Procedures : 1Prepare a steamer and set asideAlternatively, prepare a baking pan and a wire rack and preheat oven to 350°F 2In a bowl, combine all the ingredients and mix until well blended3Divide the mixture into 2 to 4 portions (depending on how many you want to make) 4Spread and flatten the mixture onto the center of each foil, divide the slices of hard cook eggs and Vienna sausagesPlace each slices at the center of each mixtureHold the foil onto your hand and roll until the ends of the mixture covers the eggs and sausagesAlternatively, by holding each ends of the foil, roll the mixture back and forth until it covers the slices of eggs and sausages in the center 5Finally, roll the aluminum foil into a tightly packed log about 1 to 2 in diameter, sealing on both endsRepeat with the remaining pork mixture 6Place the embutido in a steamer and steam for an hourAlternatively, place embutido in a wire rack on a baking pan, half filled with hot waterCover with aluminum foil (Be sure the steam will not escape)Steam-bake in the center of the oven for an hour7Remove from the ovenLet it cool and slice into ringsServe with your favorite catsup or sauces8Refrigerate unused embutido.

- Q: Where can I get Aluminum telescoping tubing in the US? It needs to be square 2.5 x 2.5 Inwith a .125 Inwall, 2.25 x 2.25 in x .125 wall, and 2 x 2in x.125 wallAnd each section needs to be about 8’ long.Any suppliers?Thanks in advance.

- Look up in the yellow pages Steel warehouse suppliersThey also carry aluminum tubingIn the central states the 2 that I know of is Central Steel and wireAnd J.T.Ryerson.

- Q: Aluminum ion doesn't hurt your brain? Is that dangerous? Why?

- In the use of aluminum foil for cooking, recommended to choose slightly thick, too thin and fragile, and if you are not careful with food eaten with the acid will in vivo for chemical reaction, then aluminum salt is generated directly absorbed by the body. So, in order to keep fit, pay attention to the thicker foil!

- Q: This is my first time cooking a turkey dinner, so i have a couple of questions???Do cook the Turkey with the Skin or without it ???Does the trukey comes out jucier if i cook it on a bag or cover it with foil paper???Also how do i cover the Turkey with the foil paper do I just put it on top or do I wrap it up around the turkey (if using foil)Also around how much time does cooking a turkey takes???Any suggestions, tips, or answers, are welcome they would be very helful and useful thanks.

- To make a juicy turkeySoak the turkey in a brine 8 hours before cookingThen drain itPat it dryYou'll have a moist flavored turkey Leave the skin on, that's the best part! I put oil on the turkey so the skin becomes crispyI like to cook the turkey at 450 degrees for the first 45 minutesThis will seal the meat of the turkey so the juices don't evaportateThen put aluminum foil over the entire turkey so that it doesn't dry out and cook at a lower tempex325 degrees for the remaining timeBase constantly every 25 minutes These are just suggestionsGood luckGood luck.

Send your message to us

Aluminum Foil Candle Insulated Aluminum Panel Insulated Ductwork

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords