Reynolds Wrap Aluminum Foil Costco Insulated Ducts Epoxy Coated Aluminum Foils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Epoxy Coated Aluminum Foils Used for Insulated Ducts

We specialize in epoxy coated aluminum foils used for insulated ducts. Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Epoxy Coated Aluminum Foils Used for Insulated Ducts

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

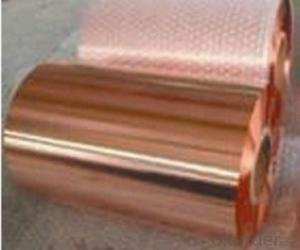

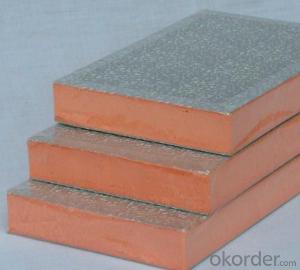

3. Epoxy Coated Aluminum Foils Used for Insulated Ducts Images

4.Specification of Epoxy Coated Aluminum Foils Used for Insulated Ducts

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Whats the difference between a base mustang and a premium as far as looks? the front looks different?

- I think you're stuckPeople actually use kool-aid as a dye.

- Q: what can i add in the aluminum foil with the potatoes to add flavor?

- I will normally just use a little salt and pepper, but you could add some mint leaves, or crushed garlic and sliced onions and some oilI would toss all of them together in a bowl before make the foil pockets, make them different shapes for each if that a re different sizes for kids and adultsYou could use butter instead of the oil if you wishedDune

- Q: I have a mercury outboard 150hp 2.0L, cannot find the id plate but i find a round aluminum plate at the top of the motor that have 0g167670 that i think is the SN, can anyone tell me what year is this motor? i am guessing 94 or 95.

- we need a picturea serial number does nothing for us as we are not a mercury dealer.

- Q: An industrial electrolytic process for producing aluminum uses the reactions shown in the following equations.Anode (oxidation): C(s) + 2 O^2- (aq) -gt; CO2(g) + 4e- (electrons)Cathode (reduction): Al3+ (l) + 3e- -gt; Al(s)a) How long would it take to produce enough aluminum to make a case (24 cans) of aluminum soft drink cans if each can used 5.00 g of aluminum, a current of 5.00 x 10^4 A was employed, and the current efficiency was 91.1%?3a) What current would be needed to electroplate 40.0 g of zinc in exactly 3 hours from a solution of zinc nitrate?

- Start of with a good allroundersee link below and a tripod, once you master the technical stuff through a class or good reading (been to the library lately?) then in a year or two when you've seen your results and had a chance to save some $$$ you might consider advancing to a DSLR.

- Q: Okay, for science I we are supposed to make a icecube holder house thing that can insulate heat well.these are the materials we can use to make an insulator:cotton ballsa small drinking cupaluminum foilconstruction papercupcake paper or tinbubble wrap (small bubbles)bubble wrap (big bubbles)mylar square3quot; of masking tapecraft stick?Foam squaresfelt squaresJust list which ones are the best please.And no I'm not cheating we are supposed to research this

- Stomach Sounds Like Water

- Q: my family uses gift wrap to wrap Christmas presents and things,which do you prefer to use and why?

- Aluminum is non-combustible and is perfectly safeYou should never smoke out of anything that contains copper though, it emits a toxic gas that can cause lock-jaw and even death, same goes for any galvanized metals.

- Q: so i'm suppose to make a boat out of some sort of metal and has to fit in a 15 by 15 cm area.the boat has to be less than the weight of 10 pennies and has to hold at least 50.questions:1what kinds of metal should i use? i'm thinking of using aluminum foilanything else?2should i make a specific design? my first prototype looks like a tuna can shape

- Aluminum foil is just about the only thing that would meet the conditions of this experimentIf I were you, I would make it bowl shaped and as big as you can get it, in the space allowed.

- Q: Aluminum foil, wooden ruler, best cotton and nylon rope which sound effect?Talk about reason ~!

- You ask the spreading speed and effect? Spreading velocity and effect is not the same thing, if it is the propagation velocity of aluminum foil is the fastest, followed by a wooden ruler, again thread, the slowest is nylon.

- Q: It comes with a trailer that is also in great shape and a brand new trolling motor as well as a Garmin GPS/FishfinderThe motor fires right up!

- Fiber One granola BarsThe peanut butter ones are fantastic!

- Q: Apple pie is my favorite :]

- Delish Crunchy Caramel Apple Pie Ingredients for the Pie 1 pastry crust for a deep-dish pie 9-inch (homemade or store-bought) 1/2 cup sugar 3 Tbspall-purpose flour 1 tspground cinnamon 1/8 tsp salt 6 cups thinly sliced peeled apples 1 recipe crumb topping (see below) 1/2 cup chopped pecans 1/4 cup caramel topping Ingredients for the Crumb Topping 1 cup packed brown sugar 1/2 cup all-purpose flour 1/2 cup quick cooking rolled oats 1/2 cup butter Directions for the Crumb Topping Directions for Crumb Topping: 1Stir together brown sugar,flour, rolled oats2Cut in 1/2 cup butter until topping is like course crumbsSet asideDirections for the Pie 1In a large mixing bowl, stir together the sugar, flour, cinnamon and salt2Add apple slices and gently toss until coated3Transfer apple mixture to the pie shell 4Sprinkle crumb topping over apple mixture5Place pie on a cookie sheet so the drippings don't drop into your oven6Cover edges of pie with aluminum foil7Bake in a preheated 375 oven for 25 minutesThen remove foil and put back in for another 25 to 30 minutes without foil8Remove from ovenSprinkle pie with chopped pecans then drizzle with caramel on top9Cool on a wire rack and enjoy warm or at room temperature.

Send your message to us

Reynolds Wrap Aluminum Foil Costco Insulated Ducts Epoxy Coated Aluminum Foils

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords