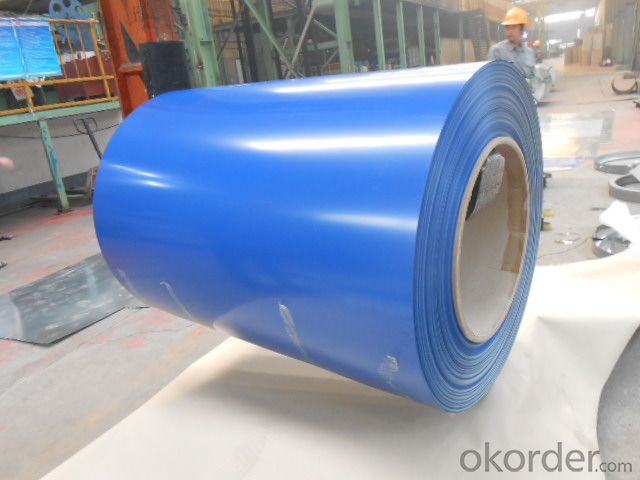

PPGI Color Coated Galvanized Steel Coil Prime Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Does steel contain nickel?

- Steel okorder /... So take a magnet to the steel in question: if the magnet sticks, the steel is unlikely to contain nickel.

- Q: How are steel coils used in the production of metal enclosures?

- Due to their versatility and strength, steel coils find extensive use in the manufacturing of metal enclosures. Typically made from high-quality steel, these coils serve as the primary raw material for producing metal enclosures. To begin with, specialized machinery is employed to unroll and flatten the steel coils to the desired thickness. This step ensures that the coils are suitable for further processing. Subsequently, the flattened steel is cut into specific sizes and shapes, according to the design requirements of the metal enclosure. Following this, various techniques such as bending, folding, and welding are utilized to mold the cut steel pieces into the desired shape. These processes enable the steel to be formed into the required dimensions and structure of the metal enclosure. The inherent strength and durability of the steel coils ensure that the final product is robust and capable of withstanding external forces or impacts. Moreover, steel coils can be coated with protective layers such as galvanization or powder coating to enhance their resistance to corrosion, rust, and other environmental factors. This coating helps to extend the lifespan of the metal enclosure while maintaining its aesthetic appeal. Furthermore, the use of steel coils in the production of metal enclosures allows for customization and flexibility. The coils can be easily manipulated to create complex shapes or designs, facilitating the customization of enclosures to meet specific customer requirements. This adaptability makes steel coils a preferred choice in industries such as automotive, electronics, and construction, where metal enclosures are widely used. In conclusion, steel coils are essential in the manufacturing of metal enclosures as they provide a strong and versatile raw material. These coils are transformed into the desired shape and size, ensuring the durability and functionality of the enclosures. With their customizable nature and protective coatings, steel coils offer a cost-effective solution for producing high-quality metal enclosures.

- Q: What are the factors to consider when selecting steel coils for a specific application?

- When selecting steel coils for a specific application, there are several factors that need to be considered. These factors include the type of application, the required strength and durability, the desired aesthetic appearance, the budget, and any specific industry standards or regulations that need to be met. Firstly, it is important to determine the type of application for which the steel coils will be used. Different applications may require different types of steel with varying properties. For example, if the coils will be used in structural construction, high-strength steel with excellent structural integrity may be required. On the other hand, if the coils will be used in automotive manufacturing, steel with good formability and weldability may be more suitable. The required strength and durability is another crucial factor to consider. This includes factors such as the load-bearing capacity, resistance to corrosion, and ability to withstand extreme temperatures or environmental conditions. The steel coils must be able to withstand the specific stresses and strains that will be placed upon them in the intended application. The desired aesthetic appearance is also important, especially in applications where the steel coils will be visible. Factors such as the surface finish, color, and texture of the steel coils may need to be considered. This is particularly relevant in industries such as architecture or interior design, where the visual appeal of the steel is a key consideration. Budgetary constraints should also be taken into account when selecting steel coils. Different grades and types of steel can vary significantly in price. It is important to find a balance between the desired properties and the available budget. Sometimes, it may be necessary to compromise on certain factors in order to meet budgetary constraints. Lastly, any specific industry standards or regulations should be considered when selecting steel coils. Certain industries, such as aerospace or automotive, may have strict requirements for the materials used in their products. In such cases, it is crucial to ensure that the selected steel coils meet all necessary standards and regulations. In conclusion, when selecting steel coils for a specific application, factors such as the type of application, required strength and durability, desired aesthetic appearance, budget, and industry standards or regulations should all be carefully considered. By taking these factors into account, one can make an informed decision and choose the most suitable steel coils for their specific application.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are widely regarded as superior to other types of metal coils due to their exceptional strength and durability. Steel is known for its high tensile strength, which means it can withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Steel can be coated with various protective layers, such as zinc or paint, to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a wide range of mechanical properties, which can be tailored through different manufacturing processes. This allows for the production of steel coils with specific characteristics, such as high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. Compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils stand out due to their exceptional strength, durability, corrosion resistance, versatility, and affordability. These characteristics make steel coils a preferred choice for a wide range of industries, from construction and manufacturing to transportation and energy.

- Q: What is the difference between steel coils and steel sheets?

- Steel coils and steel sheets are both forms of steel, but they have distinct differences. Steel coils refer to a long, continuous roll of steel that is wound up into a coil shape. These coils are usually produced at a steel mill and are typically used for further processing or manufacturing purposes. Steel coils are commonly used in various industries such as automotive, construction, and appliance manufacturing. They are often used to produce different products like pipes, tubes, and automotive parts. On the other hand, steel sheets are flat pieces of steel that are typically cut from steel coils. These sheets are available in various sizes and thicknesses, making them versatile for different applications. Steel sheets are commonly used in construction projects, such as roofing, siding, and structural components. They are also used in manufacturing processes, such as stamping, forming, and fabrication of various products. One key difference between steel coils and steel sheets is their shape and form. Steel coils are in a rolled, cylindrical form, while steel sheets are in a flat, rectangular shape. This difference in shape makes steel coils more suitable for continuous production processes, while steel sheets are used for specific applications that require flat surfaces. Another difference is the handling and transportation of these steel forms. Steel coils are typically transported and stored using special equipment, such as coil cars or cranes, due to their large size and weight. Steel sheets, on the other hand, can be easily stacked, transported, and stored using conventional methods. Lastly, the processing requirements of steel coils and steel sheets differ. Steel coils often undergo additional processing steps, such as slitting, cutting, or coating, to meet specific customer requirements. Steel sheets, on the other hand, may require minimal processing before being used in their intended applications. In summary, steel coils and steel sheets differ in their shape, handling, transportation, and processing requirements. Steel coils are rolled, cylindrical forms used for further processing, while steel sheets are flat pieces cut from coils and used for specific applications. Understanding these differences is crucial in selecting the appropriate steel form for a particular project or manufacturing process.

- Q: What is the size range of steel coils?

- The size of steel coils can vary depending on the specific application and industry, offering a wide range of options. Steel coils are available in various sizes to meet different needs. The width of steel coils can range from a few inches to several feet, accommodating different requirements. Similarly, the thickness of steel coils can vary from very thin gauges, like 0.005 inches, to thicker gauges that exceed 0.5 inches. The length of steel coils is typically determined by the manufacturing process, but it can be customized to meet specific demands. In general, the size range of steel coils is extensive, providing flexibility and adaptability in industries like automotive, construction, and manufacturing.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. They are often recycled and used in various industries such as automotive, construction, and manufacturing. The coils can be melted down and reshaped into new products, reducing the need for new raw materials and promoting sustainability.

- Q: What are the quality standards for steel coil production?

- The quality standards for steel coil production typically include factors such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards and specifications. These standards ensure that the steel coils meet the required strength, durability, and performance criteria, and are suitable for various applications in industries like automotive, construction, and manufacturing.

- Q: What are the different types of steel coil handling attachments?

- There are several different types of steel coil handling attachments that are commonly used in industrial settings. These attachments are designed to safely and efficiently handle steel coils of various sizes and weights. One type of steel coil handling attachment is the coil lifter. This attachment is typically made of durable steel and is designed to securely grip the steel coil. It features a set of adjustable arms or hooks that can be positioned to fit the specific size and shape of the coil. Coil lifters are often used in conjunction with cranes or other lifting equipment to safely transport steel coils. Another common type of attachment is the coil grab. Similar to a coil lifter, a coil grab is used to securely grip and lift steel coils. However, coil grabs often feature a more compact design and are typically used in applications where space is limited. They can be operated manually or attached to a crane or forklift. Additionally, there are coil tongs that are specifically designed to handle smaller steel coils. These tongs are often used in manufacturing or processing facilities where coils need to be lifted and moved within a confined space. Coil tongs typically feature a set of adjustable jaws that can be positioned to grip the coil securely. In some cases, magnetic attachments are used to handle steel coils. These magnets are designed to attract and hold onto the steel, allowing for easy lifting and transportation. Magnetic attachments are often used in applications where other types of attachments may not be suitable, such as in environments with extreme temperatures or where the steel coils are coated. It is important to note that the specific type of steel coil handling attachment used will depend on the size and weight of the coils, as well as the specific requirements of the application. Industrial equipment suppliers can provide guidance on selecting the most appropriate attachment for a particular situation.

- Q: Is there alloys in low carbon steel or non

- Hello, okorder Hoping this can help you. :-)

Send your message to us

PPGI Color Coated Galvanized Steel Coil Prime Blue

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords