Polyvinyl Chloride Waterproof Membrane for Roof Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

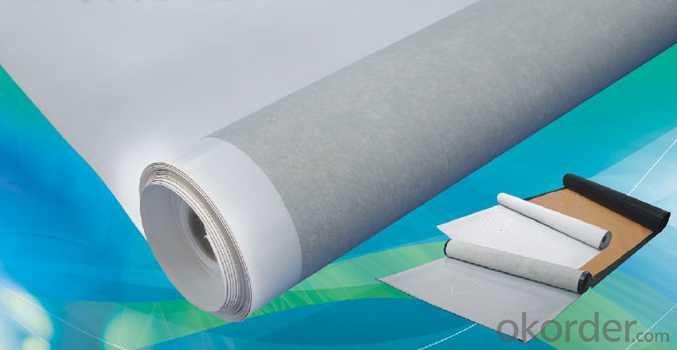

Introduction of PVC Waterproofing Membrane

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Characteristic of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Yes, there are several specific considerations for installing a waterproofing membrane on concrete surfaces. Firstly, it is important to ensure that the concrete surface is clean, dry, and free from any loose materials, oil, grease, or other contaminants. Any dirt or debris on the surface can prevent proper adhesion of the waterproofing membrane, compromising its effectiveness. Secondly, it is crucial to inspect the concrete surface for any cracks, spalling, or other damage. These defects should be repaired prior to installing the waterproofing membrane, as they can allow water to penetrate through the membrane and compromise its ability to protect the concrete. Additionally, the type of waterproofing membrane chosen should be suitable for the specific conditions and requirements of the project. There are various types of membranes available, such as sheet membranes, liquid-applied membranes, or cementitious coatings. Each type has different application methods, durability, flexibility, and resistance to various substances, so it is important to select the appropriate membrane for the specific concrete surface and its intended use. Furthermore, the installation of the waterproofing membrane should be carried out in accordance with the manufacturer's instructions. This includes applying the membrane at the recommended thickness, ensuring proper overlap and adhesion of the membrane seams, and using any recommended primers or adhesives. Lastly, it is important to consider the long-term maintenance and durability of the waterproofing membrane. Regular inspections, maintenance, and repairs should be conducted to ensure the membrane remains intact and effective in preventing water penetration.

- Q: Can a waterproofing membrane be used for historic preservation projects?

- Yes, a waterproofing membrane can be used for historic preservation projects. Historic buildings often require special attention to preserve their original architecture and materials. Waterproofing membranes can be applied to protect historic structures from water damage, which can lead to deterioration and decay. These membranes are designed to be flexible, durable, and long-lasting, making them suitable for use on historic buildings. They can be applied to roofs, walls, and foundations to prevent water infiltration and ensure the preservation of the building's structural integrity. However, it is important to consult with preservation experts and adhere to appropriate preservation guidelines to ensure that the use of a waterproofing membrane is compatible with the building's historical significance and does not compromise its authenticity.

- Q: Can waterproofing membranes be used in cold climates?

- Yes, waterproofing membranes can be used in cold climates. In fact, they are specifically designed to provide protection against moisture and water infiltration in various weather conditions, including cold temperatures. These membranes are typically made from durable, flexible materials that can withstand freezing temperatures without cracking or deteriorating. Additionally, some waterproofing membranes come with added features like thermal insulation, which helps to prevent heat loss and maintain a comfortable indoor environment in cold climates. Overall, waterproofing membranes are an effective solution for ensuring the integrity and longevity of structures in cold weather conditions.

- Q: Can waterproofing membranes be used on underground structures?

- Indeed, underground structures can make use of waterproofing membranes. These membranes have been designed with the aim of creating a barrier against water infiltration and are widely utilized in various applications, including basements, tunnels, and underground parking lots. The main objective of employing waterproofing membranes in underground structures is to avert water penetration, as this can lead to structural damage and compromise stability. Generally, these membranes are crafted from materials like modified bitumen, PVC, EPDM, or HDPE, all of which possess outstanding water resistance properties. By applying waterproofing membranes correctly, a continuous and robust barrier is established, preventing water from seeping through the walls, floors, or foundations of underground structures. These membranes can be installed externally or, on occasion, as an integral part of the concrete walls or floors during construction. In addition to their water resistance capabilities, waterproofing membranes also offer protection against other elements such as chemicals, gases, and radon. They prove highly effective in preventing issues related to moisture, like the growth of mold, the deterioration of building materials, and structural damage, thus ensuring the durability and integrity of underground structures. It is crucial to bear in mind that the proper installation and maintenance of waterproofing membranes are of utmost importance for their effectiveness. It is advisable to engage the services of a qualified professional who can assess the specific requirements of the underground structure and recommend the appropriate type of waterproofing membrane and installation method. All in all, waterproofing membranes serve as a dependable and efficient solution for preventing water infiltration in underground structures, providing long-lasting protection and preserving the structural integrity of the building.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Yes, a waterproofing membrane can be used on masonry surfaces. In fact, applying a waterproofing membrane on masonry surfaces is a common solution to prevent water infiltration and damage. Masonry surfaces such as concrete, brick, or stone are porous and can absorb water, which can lead to structural damage, mold growth, and deterioration over time. A waterproofing membrane acts as a barrier, preventing water from seeping into the masonry and protecting it from moisture-related issues. It is important to choose a waterproofing membrane that is specifically designed for masonry surfaces and follow the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used for plaza decks?

- Yes, a waterproofing membrane can be used for plaza decks. Plaza decks are typically outdoor spaces that require protection from water infiltration to prevent damage to the underlying structure. Waterproofing membranes are designed to create a barrier that prevents water from seeping into the deck and causing issues such as leaks, deterioration, and structural damage. These membranes are often made of materials such as bitumen, rubber, or polyurethane, which are highly resistant to water penetration. By installing a waterproofing membrane on a plaza deck, it ensures that the deck remains watertight and protects the integrity of the entire structure. Additionally, these membranes can also provide added benefits such as UV resistance, durability, and ease of maintenance, making them an ideal solution for plaza decks.

- Q: Are there any specific considerations for installing a waterproofing membrane on stucco surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on stucco surfaces. Firstly, the stucco surface needs to be clean, dry, and free from any loose debris or contaminants. It is important to ensure that the stucco is properly cured before applying the membrane. Additionally, the choice of waterproofing membrane should be compatible with stucco, considering factors such as flexibility, breathability, and adhesion. Proper application techniques, including thorough coverage and proper overlap of the membrane, are crucial to guarantee its effectiveness. It is also advisable to consult with a professional to ensure the correct installation process and product selection for the specific stucco surface.

- Q: Are waterproofing membranes suitable for indoor applications?

- Yes, waterproofing membranes are suitable for indoor applications. Waterproofing membranes are designed to prevent water penetration and moisture buildup, making them an ideal solution for areas that are prone to water damage, such as basements, bathrooms, and kitchens. These membranes create a barrier that prevents water from seeping through floors, walls, or other surfaces, effectively protecting the structure from water-related issues like mold, rot, and structural damage. Additionally, waterproofing membranes can also help regulate humidity levels, leading to a more comfortable and healthier indoor environment.

- Q: Can a waterproofing membrane be used for roofing applications?

- Yes, a waterproofing membrane can be used for roofing applications. Waterproofing membranes are specifically designed to prevent water infiltration, making them ideal for protecting roofs from leaks and water damage. They provide a durable and effective barrier against moisture, ensuring the roof remains watertight.

- Q: Are waterproofing membranes resistant to high temperatures?

- Waterproofing membranes can vary in their resistance to high temperatures depending on the specific material used. Some waterproofing membranes are designed to withstand high temperatures without losing their effectiveness or integrity. These membranes are often made from materials such as modified bitumen or synthetic rubber, which have high temperature resistance properties. However, it is important to note that not all waterproofing membranes are resistant to high temperatures. Some membranes made from PVC or other thermoplastic materials may have limitations when exposed to extreme heat. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to ensure that the chosen waterproofing membrane is suitable for the intended application and can withstand the anticipated temperature conditions.

Send your message to us

Polyvinyl Chloride Waterproof Membrane for Roof Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords