Polyvinyl Chloride Waterproof Membrane for Water Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

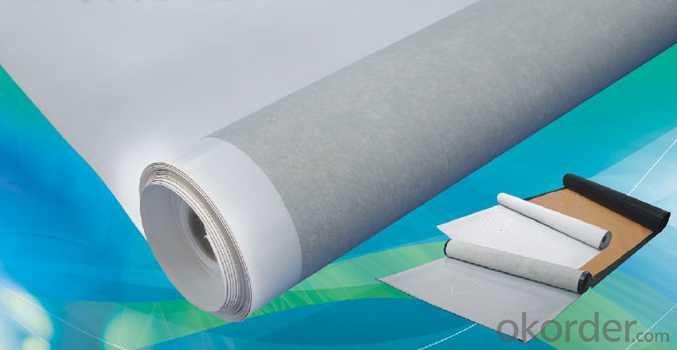

Introduction of PVC Waterproofing Membrane

Polyvinyl chloride the pvc waterproofing plastic membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Characteristic of PVC Waterproofing Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

Applicable scope

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

Cautions

1.Do not put the membrane on a pollution, water and ice ground.

2.Construcion of waterproof layer operations can't be crossed, device shall be installed on the waterproof layer, parts should be done to strengthen the basis of device and to take protective measures.

3.Do not touch the waterproof layer with thorn sharp objects after it's has been completed, don't put sundries or any additional buildings above the waterproof layer to avoid damaging it.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used in below-grade applications?

- In below-grade applications, such as basements or underground structures, it is crucial to utilize a waterproofing membrane. This membrane serves as a barrier, preventing water infiltration and the resulting structural damage or moisture-related issues. These areas are particularly vulnerable to moisture and water damage, making the use of a waterproofing membrane necessary. By preventing water from seeping through the walls or floors, the membrane keeps the below-grade areas dry, thus safeguarding the building's integrity and creating a safe and habitable environment. Waterproofing membranes designed for below-grade applications are made of durable materials that are resistant to water and possess high tensile strength to withstand ground pressure. Furthermore, they are specifically designed to adhere tightly and securely to various substrates, such as concrete. In summary, incorporating a waterproofing membrane into below-grade applications is essential for maintaining a moisture-free and structurally sound space.

- Q: Can a waterproofing membrane be used on precast concrete surfaces?

- Yes, a waterproofing membrane can be used on precast concrete surfaces. It helps to prevent water penetration and protect the concrete from moisture damage.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some common tools include a trowel, utility knife, paint roller, brush, and caulking gun. Additionally, a heat gun or torch may be needed for certain types of membranes that require heat activation. It is important to follow the manufacturer's instructions and recommendations for the specific membrane being installed to ensure proper installation and effectiveness.

- Q: Can a waterproofing membrane be used for elevator pits and sump pits?

- Yes, a waterproofing membrane can be used for elevator pits and sump pits. Elevator pits and sump pits are generally prone to water leakage and moisture issues, which can cause damage to the structural integrity of the pits and surrounding areas. To prevent such issues, waterproofing membranes are commonly used to create a barrier against water intrusion. A waterproofing membrane is designed to be highly resistant to water penetration and can effectively seal the elevator and sump pits, preventing water from seeping in. These membranes are typically made of materials such as rubberized asphalt, ethylene propylene diene terpolymer (EPDM), or polyvinyl chloride (PVC) and are applied to the walls and floors of the pits. By installing a waterproofing membrane, the elevator and sump pits can be protected from water damage, including potential corrosion, mold growth, and structural deterioration. This not only helps to maintain the functionality and longevity of the pits but also ensures a safe and healthy environment for occupants and equipment. However, it is important to consider the specific requirements and regulations of elevator and sump pit installations, as different jurisdictions may have specific codes and standards that need to be followed. Additionally, proper installation and regular maintenance of the waterproofing membrane are crucial to ensure its effectiveness in preventing water infiltration.

- Q: Are waterproofing membranes resistant to mold and mildew?

- Yes, waterproofing membranes are resistant to mold and mildew. They create a barrier that prevents moisture from seeping through, which helps inhibit the growth of mold and mildew.

- Q: Is a waterproofing membrane resistant to abrasion?

- A waterproofing membrane is generally able to resist abrasion. Its purpose is to create a protective barrier against water and moisture infiltration. These membranes are typically constructed from durable materials like PVC, TPO, or EPDM, which possess a high resistance to abrasion. Consequently, they can endure normal wear and tear that may arise during installation or due to foot traffic or other mechanical activities. Nonetheless, it is crucial to acknowledge that the level of resistance to abrasion can vary based on the specific type and quality of the membrane, as well as the conditions in which it is employed or utilized. Therefore, it is always advisable to refer to the manufacturer's guidelines and specifications to ensure the proper selection and installation of a waterproofing membrane.

- Q: Can a waterproofing membrane be used for underground utility tunnels?

- Underground utility tunnels can benefit greatly from the use of a waterproofing membrane. This membrane, a thin layer of material, is applied to the surface of structures to prevent water or moisture from entering. It is commonly used in construction to safeguard buildings and structures from water damage. In the case of underground utility tunnels, where the risk of water infiltration is high due to surrounding soil and groundwater, a waterproofing membrane is extremely advantageous. It acts as a reliable barrier, effectively blocking water from entering the tunnel and causing harm to the utilities inside. There are various types of waterproofing membranes available, such as sheet membranes, liquid membranes, and spray-applied membranes. These membranes are typically made from materials like asphalt, modified bitumen, polyurethane, or rubberized asphalt. They are designed to be durable, flexible, and resistant to water and other environmental factors. Proper surface preparation is essential before applying a waterproofing membrane to an underground utility tunnel. The surface should be thoroughly cleaned, free of debris, and in good condition. Following the manufacturer's instructions, the membrane should then be installed, ensuring that all seams and joints are adequately sealed to create an uninterrupted water-resistant barrier. It's important to note that waterproofing membranes alone are not sufficient for protecting underground utility tunnels. They should be used in conjunction with other waterproofing measures, such as proper drainage systems, to ensure comprehensive water protection. Regular inspection and maintenance of the membrane are also necessary to promptly address any damage or deterioration. In conclusion, a waterproofing membrane is an effective solution for safeguarding underground utility tunnels against water infiltration. By establishing a strong and durable barrier against moisture, it helps maintain the integrity of utilities and prolong the lifespan of tunnel infrastructure.

- Q: Can a waterproofing membrane be used on TPO roofs?

- Yes, a waterproofing membrane can be used on TPO roofs. TPO (thermoplastic olefin) is a popular roofing material that is known for its durability and energy efficiency. However, like any roofing material, TPO roofs can still be susceptible to leaks and water damage over time. To enhance the waterproofing capabilities of a TPO roof, a waterproofing membrane can be applied. A waterproofing membrane is a thin layer of material that is designed to prevent water infiltration. It is typically made from synthetic materials such as modified bitumen, EPDM, or PVC. These membranes are highly effective in creating a barrier against water, protecting the underlying roof structure from leaks and potential damage. When applying a waterproofing membrane on a TPO roof, it is important to ensure compatibility between the materials. The membrane should be specifically designed for use on TPO roofs and should be approved by the manufacturer of the TPO roofing system. This will ensure that the membrane is compatible with the TPO material and will not cause any adverse reactions or void any warranties. The installation of a waterproofing membrane on a TPO roof typically involves cleaning and preparing the surface, applying a primer if necessary, and then adhering the membrane to the roof using an appropriate adhesive or heat welding method. Once installed, the membrane acts as an extra layer of protection, preventing water from penetrating the TPO roof system and causing damage. In conclusion, a waterproofing membrane can be used on TPO roofs to enhance their waterproofing capabilities and protect against leaks. However, it is important to choose a membrane that is specifically designed for use on TPO roofs and is approved by the manufacturer of the TPO roofing system. Proper installation and regular maintenance will ensure the longevity and effectiveness of the waterproofing membrane on a TPO roof.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Yes, a waterproofing membrane is resistant to mold and mildew growth. This is because waterproofing membranes are specifically designed to create a barrier against moisture, preventing water from seeping through and causing mold and mildew to grow. By effectively sealing off the area, these membranes eliminate the conditions necessary for mold and mildew to thrive, such as dampness and moisture. However, it is important to note that while the membrane itself is resistant to mold and mildew growth, it does not guarantee complete protection against these issues. Proper installation, regular maintenance, and ensuring proper ventilation are also crucial in preventing mold and mildew growth in the long term.

- Q: Can waterproofing membranes be used on concrete reservoirs?

- Yes, waterproofing membranes can be used on concrete reservoirs. These membranes provide a protective barrier against water infiltration, ensuring that the reservoir remains watertight and preventing any potential leaks or damage to the concrete structure. Waterproofing membranes are commonly used in construction to enhance the durability and longevity of concrete reservoirs.

Send your message to us

Polyvinyl Chloride Waterproof Membrane for Water Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords