Plastic Tubes - 2024 China PP-R Pipes for Industrial and Agricultural Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

The comprehensive technical performance and economic indicator of PP-R are much better than galvanized pipe, UPVC pipe, polyethylene-aluminum compound pipe, PE-X (cross-linked polyethylene) and polybutylene pipe etc. For this reason PP-R is the leading products and widely used for feed-water piping in developed countries in Europe and America.

Nowadays PPR pipes win more attention and have been used all over the whole world more widely with its excellent sanitization performance, high heat resistance, compression resistance, corrosion resistance, pliability and seismic performance which make PP-R the real environmental friendly pipe.

Application

1) Cold and hot water systems of residence and commercial buildings

2) Transportation of industrial water supply and chemical materials

3) Pure water pipe system

4) Piping networks for rainwater utilization systems

5) Irrigation agriculture and horticulture systems

6) Transportation system of drinking water production

7) Piping networks for solar plants

8) Other pipes in industry

Product Description

1.Material : | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C,T/T,D/P |

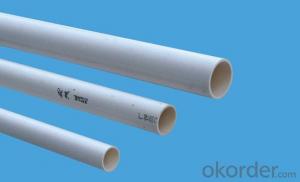

Product Show

FAQ

Q: If the products have some quality problem ,how will you deal with it?

A: If the quality problem caused by us, we will provide a replacement service,and we must keep in mind. Take measures to control quality strictly,we adhere to the principle: “ quality first”.

Q.How can I get a sample?

A: FREE SAMPLE can be sent to you .Freight will be collect

Q. Is free design assistance available for clients?

A: If you have problems in designing or beautifying the customized product, we will offer you the best design assistance.Pictures

Q:, Which factors can be customized?

A: Material, Color, Size, Packing ,Brand, delivery

Q; Advantages of your products?

A:Company products, good quality, high reputation guarantee.

- Q: How to remove dirt on the inner wall of plastic pipe?

- With a wire wrapped in absorbent cotton, soaked in water, put into the plastic pipe, wet the pipe wall, pull out the wire, stained with cleaning materials, second times into the plastic pipe, wipe back and forth, and then washed with water.

- Q: What is the minimum wall thickness for transparent plastic tubes?

- The minimum wall thickness for transparent plastic tubes can vary depending on the specific material and manufacturing process used. However, a common guideline is to have a minimum wall thickness of approximately 0.5mm to ensure structural integrity and transparency.

- Q: What's the name of that plastic tube used to fold stars?

- (1) the straw is bent back;(2) turn left pipe to the lower right;(3) turn the upper pipe to the left;(4) turn the two pipes together;(5) wrap the left tube over the right tube and fold it to the lower right;(6) wrap the upper tube over the lower tube;(7) the two pipes are turned together, with steps (4), repeating steps (4), (5), (6), (7);(8) stick the first angle close to the two pipes;(9) wrap the left tube over the first corner;(10) turn the top pipe down to the bottom;(11) repeat steps (9), (10) fold the tube to the end;(12) pass one of the tubes through the stars;(13) trim after tensioning;(14) complete

- Q: What are the common lengths of plastic tubes used for interior design?

- The common lengths of plastic tubes used for interior design can vary, but typically they come in lengths of 4 feet, 6 feet, and 8 feet.

- Q: I once saw a tunnel tube part that is just a small flat part with holes in it. It would allow you to connect, say, two cages together and allow the hamsters in those cages to see and smell each other but NOT pass through. I have been looking for this part but I cannot seem to find it again. If anyone has a website, I would appreciate it very much

- you're turning out to be a multitude and it will stink i does no longer do it sounds cool yet nasty all the way around you mustn't be waiting to get the hamster poo or pee up out of the flooring partitions tubes think of of ways your homestead will scent

- Q: What is the minimum wall thickness for plastic tubes?

- The minimum wall thickness for plastic tubes can vary depending on factors such as the material used, the intended application, and the manufacturing process. However, in general, it is recommended to have a minimum wall thickness of at least 0.5mm to ensure structural integrity and prevent issues such as deformation or breakage.

- Q: What is the minimum wall thickness of plastic tubes available?

- The minimum wall thickness of plastic tubes typically varies depending on the specific type of plastic and manufacturing processes, but it can generally range from 0.5mm to 1mm.

- Q: Can plastic tubes be used for industrial applications?

- Yes, plastic tubes can be used for a variety of industrial applications. They offer benefits such as resistance to corrosion, chemicals, and high temperatures. Plastic tubes are commonly used in industries such as plumbing, automotive, manufacturing, and construction for fluid transportation, electrical wiring, insulation, and structural support.

- Q: What are the different printing options for plastic tubes?

- There are several printing options available for plastic tubes, including screen printing, pad printing, digital printing, and heat transfer printing. Each method offers different advantages in terms of print quality, durability, and cost-effectiveness, allowing manufacturers to choose the most suitable option based on their specific needs and requirements.

- Q: How do plastic tubes compare to polyurethane tubes in terms of flexibility?

- Polyurethane tubes are generally more flexible than plastic tubes.

Send your message to us

Plastic Tubes - 2024 China PP-R Pipes for Industrial and Agricultural Fields

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords