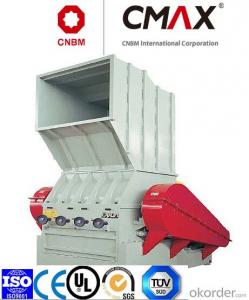

Plastic Shredder Plastic crusher Plastic Crushing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

PC series Plastic Crusher

1.high quality tool steel, cutting-tool

2,using life is very long

3,easy operation

Character of PC series Plastic Crusher:

PC series plastic crusher absorbs domestic and foreign advanced technology; it has the rational design and repeated tests and keeps improving.

The machine has some features such as light in weight, low energy consumption, good quality, long life and easy to clean. PC series plastic crusher is suitable for smashing polystyrene, polypropylene, nylon, defective plastic products of injecting and extruding machine. If you change the suitable sieve and adjust the space among the blades, it can also be used in smashing the waste of various plastic such as PVC/PP/PE films, PET bottle, and plastic sheet and so on.

plastic crusher

It is a very important machine for recycling PP PE film, PET bottles and etc plastics.

Model | Crushing room dimension (mm) | Capacity (kg/h) | Motor power | Number of fixing blade | Number of rotating blade | Machine dimension (L*W*H)mm | Weight (KG) |

PC-180 | 190*195 | 30-80 | 2.2 | 2 | 6/9 | 680*530*800 | 250 |

PC-230 | 210*230 | 50-110 | 4 | 2 | 6 | 890*650*1102 | 300 |

PC-300 | 310*240 | 100-250 | 5.5 | 2 | 9 | 1050*800*1200 | 450 |

PC-400 | 410*255 | 200-450 | 7.5 | 2 | 12 | 1200*880*1330 | 550 |

PC-500 | 510*270 | 360-720 | 11 | 4 | 15 | 1380*1000*1380 | 650 |

PC-600 | 610*270 | 470-870 | 15 | 4 | 18 | 1380*1100*1500 | 750 |

PC-500H | 510*350 | 420-720 | 15 | 4 | 9 | 1400*1100*1600 | 1000 |

PC-600H | 650*425 | 600-870 | 22 | 4 | 12 | 1400*1130*1810 | 1800 |

PC-800 | 810*520 | 800-1000 | 30 | 4 | 15 | 2080*1500*2100 | 2000 |

PC-1000 | 1001*650 | 1000-1300 | 37 | 4 | 18 | 2080*1780*2100 | 3000 |

PC-400 for film | 410*255 | 50-150 | 7.5 | 2 | 6 | 1200*880*1330 | 550 |

PC-600 for film | 610*270 | 100-250 | 15 | 4 | 6 | 1330*1100*1500 | 750 |

- Q: Plastic grinding machine mainly grinding PVC grinding material thickness of about 20 silk finger cover size, which kind of pulverizer is suitable for this purpose?

- Raymond mill mainly consists of the host, analysis machine, blower, finished cyclone separator, plumbing, motor and other components, wherein the host is composed of a machine frame, inlet volute, blade and grinding roller and grinding ring, a cover casing and a motor, auxiliary equipment, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet etc. flexible, users can choose according to the situation.

- Q: Maintenance essentials of 300 kW generator rental system for recycled plastics machines

- 5, time of tool change, the gap between the knife and the fixed knife: above 20HP crusher crusher 0.5MM 0.8MM is better, better than 20HP. The thinner the recovery material, the gap can be properly adjusted. 6, second times before the start, should first remove the machine room remaining debris, to reduce the starting resistance. The inertia cover and the belt wheel cover shall be regularly opened to remove the ash discharge at the bottom of the flange plate, and the powder discharged from the plastic crusher chamber enters the shaft bearing. 7. The machine should be kept in good condition. 8, regular inspection of plastic crusher belt is loose, timely adjustment.

- Q: Working video of aluminium crusher

- Like cans, civil aluminum (pot bowl), aluminum plate, silk belt is aluminium, aluminum content generally below 95%, as for die casting aluminum, automobile and motorcycle parts etc.

- Q: The crusher can not be broken. What happened to the stone?

- Due to improper use can often cause the phenomenon of death, so in the crusher, crushing the material, must pay attention the degree of uniformity of the material, there is the hardness of the material properly, if perfect, drum type drying machine, can add a working procedure.

- Q: What's the difference between a domestic crusher and another crusher?

- According to the different manufacturing process, it can be divided into crawler mobile crushing station and tire mobile crushing station.

- Q: Why plastic crushers are closely related to environmental protection?

- As is known to all, the decomposition of plastics is very poor. Plastic discarded, not recycled, will affect the environment. PS: we do import engineering plastics

- Q: PVC how much is a plastic crusher?

- There are many kinds of models, but the price depends on the factors of production

- Q: What kind of material is used for plastic hairpin?

- If you use recycled plastic, then in the larger plastic market there, if you need raw materials, then go to that kind of special plastic particles sold inside the shop.

- Q: Which industries will buy crushers?

- Gravel factory, sand making factory. Will buy a crusher. I suggest that we buy a crusher and buy Xin Yun heavy industries. Quality assurance is king..

- Q: What's the price of used plastic crushers?

- The machine rarely has a big problem. How about the quality of the export business?.

Send your message to us

Plastic Shredder Plastic crusher Plastic Crushing Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords