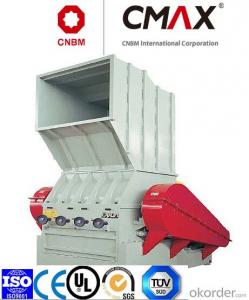

PET Bottle Crusher,Grinder wet crushing machine plastic crusher film crusher

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

500-2000 kg/h output PET Bottle Crusher,Grinder

Features:

1) The crush working space is a special design for the container shape, which is

good for quick out-put, no accumulation, no bouncing-out, no duplicated crush;

products' shapes are even without dust or tiny substance

2) Special design in the angle of rotary cutters that causes energy saving, high

efficiency, limited vibration, silence and stable out-put of electric current;

when crushing, above effects will cause long lasting in transmission and structure

of the equipments

3) Easy-open design in the equipment structure, to make an easy maintenance

of safety, quickly in a convenient way; average will save at least 1/2 than

traditional designs

4) Main bearing installed outside of the equipment body that is good for easy

maintenance and long lasting in using life, also won't be affected by the

equipment's high temperature and leaking

5) The security of equipment body and performance have matched CE standard

| Specification | Output(kg/h) | Power(kw) | No.of Rotary blade | No.of Fixed blade | Rotor Diameter(mm) | Size of Feeding Hopper(mm) |

| SPC500/500 | 500 | 45 | 8 | 3 | Φ 500 | 500*500 |

| SPC500/1000 | 1000 | 55 | 16 | 6 | Φ 500 | 500*1000 |

| SPC700/1000 | 1500 | 75 | 16 | 6 | Φ 700 | 700*1000 |

| SPC800/1200 | 2000 | 110 | 16 | 6 | Φ 800 | 800*1200 |

- Q:How many units should be taken for processing polyethylene granules? It is better to introduce them in detail,

- Third to have a drainage exhaust plastic extruder, used to contain water, exhaust, old plastic heating plasticization, melt extrusion plastics; the fourth to have a simple plastic extruder, after first extrusion of molten plastic after two extruded into the thin; fifth to the cooling water tank and a cutter the filament, cooled and cut into particles. The technological process is as follows:Selection, classification and cleaning of waste plastics: extrusion, plasticization, cooling, cutting and packingIf a set of extrusion granulation equipment has 20~30 square meters, the workshop is enough, but the outside of the site requires a little bigger, and at least one hundred square meters

- Q:Classification of equipment for plastics mills

- (two) powerful plastic crusher:1. The blade structure is between the claw knife and the flat knife. It is suitable for crushing the ordinary sheet, pipe, profile, plate and packing materials and other plastic products;2, universal plastic crusher, using sealed bearings, so that the rotation of the bearings for a long time to maintain good;3, design a reasonable knife, using steel blade, knife product granulating uniform, thermal processing, and through strict balance test, elegant appearance design;

- Q:How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- The same kind of waste plastics can be broken and cleaned by plastic crusher, and then heated, melted and extruded by plastic extruder

- Q:How do you make plastics into particles?

- Then, the plastic granule is obtained by heating, melting and granulating through the plastic extruder.

- Q:How often does the plastic crusher get rid of the knife?

- The material is too big, the screws aren't tight enough, the screws aren't tight, and so on

- Q:What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Of course, the crusher is the longer the better, if conditional, get two sinks, the effect is better

- Q:Packing belt above hasp can't get rid of buy a crusher can I directly broken is broken belt

- In the recycling process of waste plastics, waste a lot of it contains a lot of iron

- Q:What does the crusher crush add to the weight of the crushing material?

- Crushing materials are generally sold to plastic factories, and HDPE materials are mainly used to make pots, barrels, turnover boxes, plastic pipes, hollow products, etc.. If you want to increase the added value of the broken material, it is better to break the material into pellets, which requires a plastic granulator (you can buy simple equipment, which is cheaper).

- Q:How much does it cost to run a disposable plastic basket factory?

- Do this line of investment is relatively large, high technology, management should also keep abreast of it. In addition, the volume of products is still large enough to make money.

- Q:What are plastic particles? What's the use?

- Two vinyl chloride, bananas, water and other organic solvents. PVC is a PVC, bright color, corrosion resistant and durable. Due to an increase in the manufacturing process of plasticizer, anti ageing agent assisted a number of toxic materials, so their products generally do not store food and medicine. ABS is composed of acrylonitrile, butadiene and styrene polymerization the plastic, it eye-catching colors, heat resistance, firmness, outer surface of chromium, nickel and other metal films, making keys, buttons, knife, TV shell, umbrella handle. PA nylon plastics, its characteristic of tenacity, firmness, wear resistance, commonly used in the production of comb, toothbrush, hook, fan, rope, net fruit bags. No toxicity, but not long-term contact with acid and alkali. The use of ordinary life, renewable particles can be used to manufacture all kinds of plastic bags, cans, pots, toys, furniture, stationery and other living utensils All kinds of plastic products...... Clothing industry: recycled particles can be used to make clothing, ties, buttons, zippers...... Building materials: recycled particles can be used to make all kinds of building blocks, building tools, plastic doors and windows, mortar barrels...... Agriculture: renewable particles can be used for plastic, pump tube, farm machinery, fertilizer bags, cement packaging bags...... Machinery industry: recycled granules, after special formula, can be used to make machine parts: all kinds of bearings, gears, cams, different wheels, sealing rings, all kinds of blades, all kinds of pump impeller...... [

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET Bottle Crusher,Grinder wet crushing machine plastic crusher film crusher

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords