CMAX Light Single Axle Shredder For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Certification: CE,SGS,UL,TUV

1.High capacity

2.Good quality and reasonable price

Single Axle Shredder

1.Siemens PLC controlling System

2.Automatically reverse and forward Rotation

3.Overload Protect

WANROOETECH PNDS Single Axle Shredder:

Single Axle Shredder Product Description:

This model Plastic Shredder with small nibble type ripping teeth on the rotor assembly is one of the new applications being applied to the recycling industry for shredding high volume bulk materials, such as wood pallets, furniture parts, cardboard, plastic waste, garbage and many other reusable materials. Unique adjustment method for rotor and stator blades could double or even quadruple their life-span. Material is fed through the hopper in front of a hydraulically operated drawer, which pushes the material load-controlled onto the turning rotor. The material is shredded between the rotor knives and a fixed counter knife. The screen hole with different perforation diameters determines the size of shreds. Produced shreds can drop from the machine through the screen perforation directly or be removed with the optional suction device or spiral conveyor.

Single Axle Shredder Product Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blades has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen perforation is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc.

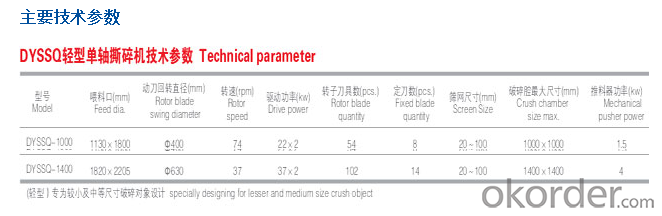

Light Single Axle Shredder Technical

To protect environment and suit for different output requirement.CNBM produce LIGHT AND HEAVY AXLE shredder.This kind of shredder is solid and wearable.It is suitable for crushing wood,different kind of plastic,plastic film and paper. Low speed rotor blade ,low noise ,high output and high save energy.

- Q:Plastic crusher is slow to eat. Why?

- Fixed, then remove the fixed knife grinding, so as to better the fixed knife.

- Q:Why plastic crushers are closely related to environmental protection?

- Plastic recycling has developed, and that has important implications for environmental protection

- Q:Points for attention of plastic recycling granulator

- 1. The granulator is running forward. Avoid reverse.2, granulation machine avoid cold machine empty stomach operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon.

- Q:Plastic crusher, food box, plastic crusher, plastic crusher how much money

- If you want to configure a higher degree of automation, if the output is large, then the small can reach 400-500KG per hour. The price is set at 5.8

- Q:In hard rock foundation construction, can not be carried out burst, crusher does not move. Is there any good way?

- There will be a lot of smoke coming out; in such a circle, a hole about 1 meters in diameter will be formed. Then it can be built with static blasting.

- Q:Which industries will buy crushers?

- Plastic crusher, as the name suggests, is broken plastic material crusher. In the injection molding machine or granulator production of raw materials and produce defective products and feed intake, can timely input machine side plastic crusher, after crushing and grinding of OK, keep clean and dry, in the "two proportional valve" proportionate conditions, raw materials and water crushing mixing, molding, manufacturing good products, recycling.

- Q:Packing belt above hasp can't get rid of buy a crusher can I directly broken is broken belt

- Except iron crusher, special crusher for packing belt, special crusher for packing belt

- Q:Working video of aluminium crusher

- Like cans, civil aluminum (pot bowl), aluminum plate, silk belt is aluminium, aluminum content generally below 95%, as for die casting aluminum, automobile and motorcycle parts etc.

- Q:What are plastic particles? What's the use?

- Two vinyl chloride, bananas, water and other organic solvents. PVC is a PVC, bright color, corrosion resistant and durable. Due to an increase in the manufacturing process of plasticizer, anti ageing agent assisted a number of toxic materials, so their products generally do not store food and medicine. ABS is composed of acrylonitrile, butadiene and styrene polymerization the plastic, it eye-catching colors, heat resistance, firmness, outer surface of chromium, nickel and other metal films, making keys, buttons, knife, TV shell, umbrella handle. PA nylon plastics, its characteristic of tenacity, firmness, wear resistance, commonly used in the production of comb, toothbrush, hook, fan, rope, net fruit bags. No toxicity, but not long-term contact with acid and alkali. The use of ordinary life, renewable particles can be used to manufacture all kinds of plastic bags, cans, pots, toys, furniture, stationery and other living utensils All kinds of plastic products...... Clothing industry: recycled particles can be used to make clothing, ties, buttons, zippers...... Building materials: recycled particles can be used to make all kinds of building blocks, building tools, plastic doors and windows, mortar barrels...... Agriculture: renewable particles can be used for plastic, pump tube, farm machinery, fertilizer bags, cement packaging bags...... Machinery industry: recycled granules, after special formula, can be used to make machine parts: all kinds of bearings, gears, cams, different wheels, sealing rings, all kinds of blades, all kinds of pump impeller...... [

- Q:What's the difference between a domestic crusher and another crusher?

- According to the different manufacturing process, it can be divided into crawler mobile crushing station and tire mobile crushing station.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Light Single Axle Shredder For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products