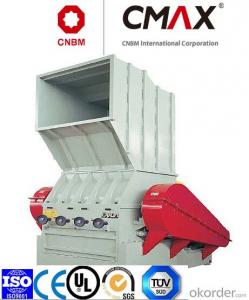

plastic shredder plastic crusher plastic crushing machine for sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Fully airtight silent designed noise below 80db without 1m away from the machine,

avoids powder contamination;

2. Elegant designed with options available;

3. Installed with heat transmitting system, expel heat generated from the electric motor,

protection and safety without any problem for long hour's operation;

4. Stainless steel material storage tank easy for cleaning and remove, stainless steel

suction spout available upon require;

5. Installed with safety protection system and CE authenticated electrical appliances

meeting the European safety standard;

6. Installed with electrical phase controller and power isolator, safety operation and

simple maintenance;

7. Installed with power isolator, safety operation and simple maintenance;

8. Movable stainless steel multi-positional tray feed and closed for complete soundproof

operation.

- Q: 600 of the plastic crusher, there are 18 pieces of moving blades, 4 fixed blade, want to ask the blade and the fixed blade of the gap is how much?Look, the machine seems to have become smaller from left to right. Is that so?

- Plastic crusher blades, also known as plastic machinery blades, a wide variety of high quality steel, with good sharpness and abrasion resistance. It is mainly used in plastics, rubber and other industries. As with other blades, it requires precise geometric tolerances to ensure good assembly quality.

- Q: Classification of equipment for plastics mills

- Motor power selection, high design accuracy1, after repeated experiments and practical use, the results show that the choice of motor power, design and efficiency of the machine matching is high, so as to ensure the constant force of the whole series of products with low energy consumption, high efficiency and long service life and so on.Reasonable design, excellent performance1, the whole body of scientific and rational design, the imported materials and high work efficiency; steel body, compact structure, strong, suitable for operation in the work environment, mechanical performance is stable and reliable, not by the crushing materials for a long time and affected.2, the separation of design, feed mill main body filter base according to the reference holes and washable screen assembly.Low noise, environmental protection, clean and pollution-free1 、 equipped with heavy load bearing and design double seal device crushing room, effectively isolate oil pollution, ensure the processing material clean. Unsafe factors resulting from unstable running and excessive motor load to prevent pulverizing powder from entering the mechanical transmission mechanism of the bearing housing.2, double deck sound insulation device, can effectively prevent vibration and noise, with high environmental protection effect.3, power consumption, energy saving, high efficiency, simple shape, easy to move.Seiko carved, superior quality1, all the parts have set the benchmark for the hole and the surface of coarse and fine multiple machining process, and execute the testing procedures according to strict standards to ensure reliable accuracy of each component, while ensuring the interchangeability of parts, greatly facilitate the use of maintenance products in the process of replacement parts.Safe and reliable handling

- Q: Plastic crusher blade easily broken, because what?

- First, the thickness of the tool is too thin, too thin, easy to break;

- Q: How to operate a plastic crusher correctly?

- Each brand is different, the use of plastic crusher will also be different

- Q: How many units should be taken for processing polyethylene granules? It is better to introduce them in detail,

- That can only be used in injection molding products like plastic woven bag is used for the production of polypropylene plastic, plastic woven bag. The production of recycled plastic particles should have a certain space, used for storage and cleaning the waste plastics; the second to have a plastic crusher used for crushing waste plastic products;

- Q: How much does it cost to run a disposable plastic basket factory?

- Do you want to have the first plastic basket according to the size of a certain area of the hydropower plant, complete; second have more than 1000 grams of plastic injection molding machine, plastic crusher and other equipment; the third to have the corresponding plastic mold products, this is not a small sum of money

- Q: How often does the plastic crusher get rid of the knife?

- The material is too big, the screws aren't tight enough, the screws aren't tight, and so on

- Q: Plastic crusher is slow to eat. Why?

- Sharpen the knife quickly. Grind the coarse sand with an angle grinder.

- Q: In hard rock foundation construction, can not be carried out burst, crusher does not move. Is there any good way?

- Cutting machine cutting width; or hammer drilling; then using hydrochloric acid into the reaction -- let

- Q: Hello everyone! I am engaged in waste plastics crushing a small factory repelleting, I have a crusher is crushing all kinds of waste plastic bottles, plastic blocks and pipes, with cleaning one broken, can put the screen into big hole, and then smash PP and PE agricultural waste sacks film can be used? You have experienced elder brother to help, thank you little brother

- Plastic properties are not the same, separate cutting, pipes need relatively strong crusher, such as broken PET, because of heat will crystallize, in the process of cutting through the tear will inevitably lead to molecular damage, there is need to consult

Send your message to us

plastic shredder plastic crusher plastic crushing machine for sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords