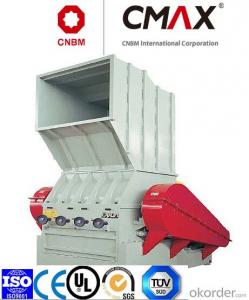

Best sale high quality plastic crusher crushing machine crusher equipment

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Used crushing all waste plastic

2.ISO9001:2000/CE

3.Quick discharge

4.High production

Product Description:

1.Strong Crusher Machine has wide application and is used for crushing and recycling various plastic products and old materials.

2.The entire machine is made of steel and features stable performance and long service life,and the machine performance won't be dropped by crushing materials after long term work.

3.Adopt heavy-load bearing and oil seal with noise-isolating board,effectively prevent vibration and assure to protect the product from oil.

4.Adopt electric control safe design,the motor is installed with overload protective device and power supply interlock protective design

for assuring safety when cleaning.

5.The cutter is flexible and adjustable,and can be sharpened repeatedly with ultra long service life.It is capable of easily crushing and cutting soft and hard plastic.

6.Combine separated design,the materials falling door and filter of crushing chamber are easily for disassembling and cleaning.The feet are installed with slide wheels with convenient movement.

TECHNICAL PARAMETERS:

Model | Diameter of Crushing Chamber(mm) | Crushing Ability()kg/h | Motor Power(kw) | Fixing Cutter(pcs) | Flexible Cutter(pcs) | Mechanical Dimension(mm) | Weight(kg) |

PC180A | 190x165 | 30-80 | 2.2 | 2 | 9 | 650x530x980 | 250 |

PC230A | 210x235 | 50-110 | 4 | 2 | 6 | 750x610x1200 | 300 |

PC300A | 310x245 | 100-250 | 5.5 | 2 | 9 | 900x760x1200 | 450 |

PC400A | 410x260 | 200-450 | 7.5 | 2 | 12 18 | 950x860x1300 | 550 |

PC500A | 510x285 | 360-720 | 11 | 4 | 15 | 1110x970x1450 | 750 |

PC600A | 610x285 | 470-870 | 15 | 4 | 18 | 1110x1070x1450 | 950 |

Strong Model | |||||||

PC450B | 440x250 | 200-500 | 11 | 2 | 21 | 1250x900x1450 | 650 |

PC500B | 510x320 | 450-720 | 11 | 4 | 6 15 | 1600x960x1710 | 1050 |

PC500C | 510x350 | 600-920 | 18.5 | 4 | 6 9 | 1300x1050x1950 | 1850 |

PC600B | 610x320 | 500-870 | 15 | 4 | 6 18 | 1770x1200x1700 | 1250 |

PC600C | 610x380 | 550-950 | 18.5 22 | 2 | 6 12 | 1400x1210x1950 | 1980 |

PC650C | 650x435 | 600-1000 | 22 | 2 | 6 | 1500x1250x2000 | 2050 |

PC800C | 810x525 | 800-1000 | 30 37.5 | 4 | 6 15 | 1700x1410x2250 | 2800 |

PC1000C | 1020x610 | 1000-1300 | 40 55 | 4 | 9 18 | 2000x1980x2650 | 3800 |

PC1000CE | 980x700 | 1000-1300 | 40 55 | 4 | 9 18 | 2150x1800x2550 | 3800 |

PC1000CA | 1001x800 | 1300-2000 | 55 75 | 4 | 9 18 | 2150x1820x3150 | 4500 |

- Q: How do you make plastics into particles?

- The heater needs to be heated first and then broken with a shredding knife.

- Q: What does the crusher crush add to the weight of the crushing material?

- Want to waste plastic products recycling broken, as long as there is a plastic crusher on it. If there are larger plastic products (such as plastic pots, barrels, bins, etc.), there is also a disc saw, used to cut large pieces of plastic into small pieces, which are easily broken into a crusher.

- Q: How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- Plastic is divided into many varieties, different plastics because of different molecular structure, solubility parameters are different, so most of the plastic can not be mixed with each other

- Q: How many categories are there in the cutter type of plastic crushers?

- 1 、 all steel welded frame, durable2, easy disassembly design, easy cleaning and maintenance3 、 imported steel cutting tools, sharp blade, easy to change, durable4, grinding all kinds of soft and hard plastic, easy and easy5. It is equipped with motor winding and interlock protection system to ensure safe use6. The minicomputer is equipped with pulleys for easy movement. The large machine has a water cooling system for easy time operation7, you can choose different tools and different hole through the screen

- Q: PVC what's the best blade for plastic crushers?

- 65Mn the most common, cheap, very sharp, the drawback is not wear-resistant. Grinds the blade original, feels that gives the minute Oh!

- Q: I want to make a plastic lid ~ ~ big barrel gasoline barrel diameter of about 58cm ~ ~ want to own processing to use what machine? How much, approximately? Where can I sell it?Every year I have about 200 thousand orders of more than cover any kind of high efficiency ~ ~ automation machine?? Can the 2~10 million machine be satisfied? And is the maintenance cost of the machine expensive?

- To an injection molding machine, plastic mould, rubber drying machine, the price, look at your request. About 3~9.

- Q: How often does the plastic crusher get rid of the knife?

- The material is too big, the screws aren't tight enough, the screws aren't tight, and so on

- Q: What are plastic particles? What's the use?

- There are dozens of common, common plastics, engineering plastics, special universal Plastics: Polyethylene polystyrene polypropylene polyvinyl chloride polyester polyurethane engineering plastics such as nylon [2]: PTFE POM poly carbon silicone special plastics: thermosetting plastic functional polymer plastics, such as artificial kidney. Heart. Blood vessels... Aerospace industry and other types of PP edit this section of recycled plastic. Polypropylene (PP) - coloring not translucent, waxy, lighter than polyethylene, transparency is better than polyethylene,

- Q: Which industries will buy crushers?

- Lime, buildings, minerals, coal, and so on, may be used more

- Q: What's the price of used plastic crushers?

- Like the crusher is basically a price, a point of goods, basically the price will not be very low.

Send your message to us

Best sale high quality plastic crusher crushing machine crusher equipment

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords