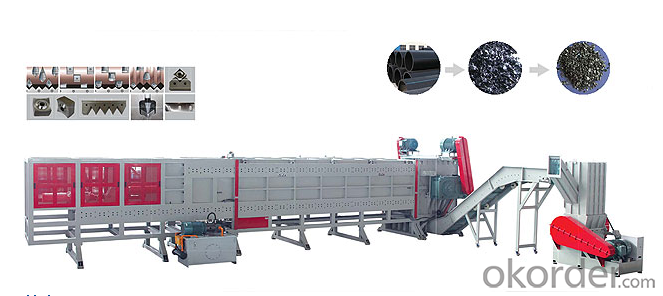

CMAX Plastic Pipe Shredder Unit For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard wooden case as usual |

| Delivery Detail: | Within 15 days after receipt of the deposit |

plastic pipe recycled bottle shredder unit

XIECHENG 30HP/22KW Crusher for Plastic Industry

1. Suitable for recycle of plastic casing, thin tube plastics, injection and mould sector, bottle plastics and shell plastics;

2. cmax series are easy to operate and simple to replace cutters. Spacious flat blade is suitable to granulate bulky and thin plastics, increases efficiency; installed with electrical safety devices; double wall hopper with sound-proof material. Motor is equipped with overload protector, and power protection devices. Safety and environmental protection, low electricity consumption and durable. Stainless steel hopper for all models is available.

plastic pipe crusher,large diameter plastic pipe crusher,plastic pipe crusher shredder machine

product show

Technical parameter:

Model | Feed dia.(MM) | Rotor blade swing diameter(MM) | rotor speed | Drive power | Max shredable pipe | Mechanical pusher power | OUTPUT(KG/H) |

CMAX-630 | 750*790 | 848 | 39 | 2*30 | 630 | 11 | 800-1000 |

CMAX-800 | 950*950 | 1028 | 33 | 2*37 | 800 | 11 | 1000-1200 |

CMAX-1000 | 1140*1160 | 1258 | 27 | 2*45 | 1000 | 15 | 1200-1500 |

CMAX-1200 | 1340*1360 | 1478 | 23 | 2*55 | 1200 | 15 | 1500-2000 |

- Q: Points for attention of plastic recycling granulator

- 3, the main bearing room at both ends of the bearing parts burned, hand burning or noise, we should stop, repair and add butter. During normal operation, the bearing chamber butter once every 5-6 days.4, pay attention to find out the law of operation of the machine, such as: machine temperature, speed, speed, according to the situation, timely processing.5, the operation is stable, should pay attention to check the gap coupling agreement is too tight, to timely adjust some loose.

- Q: Plastic crusher blade easily broken, because what?

- Second, the brittleness of the tool's steel is only the main reason for the collapse;

- Q: Is the waste plastics crusher harmful to the environment when it is produced?

- Low carbon, energy saving, low noise, tearing materials, recycling, and so on.It's the latest plastic shredder machine:

- Q: How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- Plastic is divided into many varieties, different plastics because of different molecular structure, solubility parameters are different, so most of the plastic can not be mixed with each other

- Q: Why plastic crushers are closely related to environmental protection?

- Because there is a good plastic crusher, which means that the plastics recycling industry market will be better development

- Q: Packing belt above hasp can't get rid of buy a crusher can I directly broken is broken belt

- In the recycling process of waste plastics, waste a lot of it contains a lot of iron

- Q: I want to make a plastic lid ~ ~ big barrel gasoline barrel diameter of about 58cm ~ ~ want to own processing to use what machine? How much, approximately? Where can I sell it?Every year I have about 200 thousand orders of more than cover any kind of high efficiency ~ ~ automation machine?? Can the 2~10 million machine be satisfied? And is the maintenance cost of the machine expensive?

- Machine maintenance costs include hydraulic oil costs, electrical components costs, 2~5 yuan per year. The above estimate, the detailed estimate should be based on the advanced level of equipment and manufacturers, and I hope you can carefully select the products suitable for your products.

- Q: How do plastic particles agglomerate?

- There are special crushers now, but I know the crusher is used in traffic, road construction, cement, lime and so on. It should be used for plastics

- Q: Plastic crusher is slow to eat. Why?

- Sharpen the knife quickly. Grind the coarse sand with an angle grinder.

- Q: Hello everyone! I am engaged in waste plastics crushing a small factory repelleting, I have a crusher is crushing all kinds of waste plastic bottles, plastic blocks and pipes, with cleaning one broken, can put the screen into big hole, and then smash PP and PE agricultural waste sacks film can be used? You have experienced elder brother to help, thank you little brother

- Plastic properties are not the same, separate cutting, pipes need relatively strong crusher, such as broken PET, because of heat will crystallize, in the process of cutting through the tear will inevitably lead to molecular damage, there is need to consult

Send your message to us

CMAX Plastic Pipe Shredder Unit For PE/PP/PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords