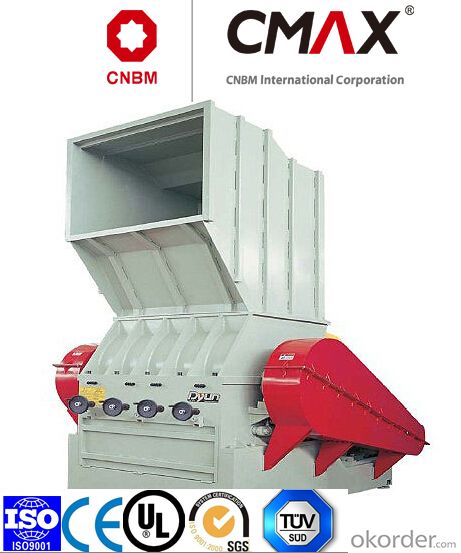

CMAX High Output CMAX Thin-film Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

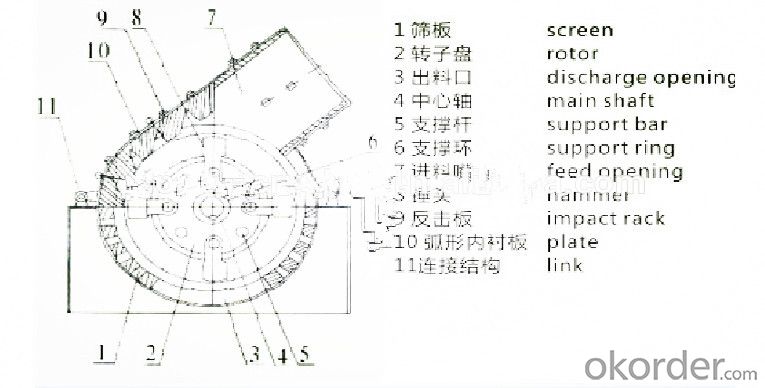

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

technical data

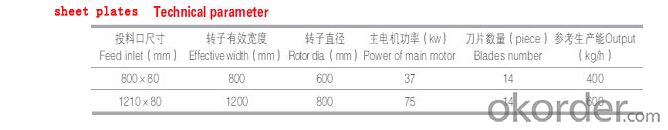

sheet plates technical

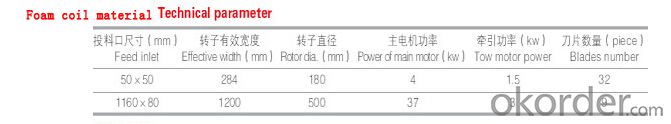

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Plastic crusher, food box, plastic crusher, plastic crusher how much money

- If you want to configure a higher degree of automation, if the output is large, then the small can reach 400-500KG per hour. The price is set at 5.8

- Q: How to calculate the crushing capacity of a coal crusher?What's the formula?

- In a certain range, the increase of the eccentric shaft rotation can improve the crusher production capacity, but also increase the unit weight of ore crushing power consumption. The speed is too large, will have been broken in the crushing chamber of the ore to discharge, and blockage phenomenon, but to reduce production capacity, power consumption increases, therefore, E-breakers should be one of the most suitable speed.

- Q: What does the crusher crush add to the weight of the crushing material?

- In fact, glass fiber reinforced plastic can also be regarded as a kind of plastic, although it is better than ordinary plastic strength, to be resistant, after all, it contains a lot of resin. If you want to break to about a centimeter, you can use Reed's single shaft crusher, lower production, but less investment. If you want to break to more than two centimeters, and the output is large, it is recommended to use Sred powerful biaxial crusher. The two machines are free of dust and low noise.

- Q: How do you melt plastics?I would like to waste plastic (such as: pots, shells), melting and forming, as a useful equipment shell (such as: sound shell). But plastic is non crystal, how to melt like a crystal, please advise!

- The same kind of waste plastics can be broken and cleaned by plastic crusher, and then heated, melted and extruded by plastic extruder

- Q: What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Your shaft is broken. Is it too deep at the bottom of the bar to eat too much? The exhaust is empty and the material is normal

- Q: What's the difference between a domestic crusher and another crusher?

- According to the different manufacturing process, it can be divided into crawler mobile crushing station and tire mobile crushing station.

- Q: How should the plastic crusher blade be ground?

- First sharpen the edge of the blunt knife, then fine grinding, sharpening the sharp edge

- Q: What are the differences between plastic crushers and particle machines, as well as the amount of money needed to buy machines and running capital? How much do I have to do to make it work? Yes, there are machines to buy machines, washing machines and crushers, and so on. Is everything a set? How much is the set? I'll do that. I'll go to the manufacturer and find the Department in it. And how do I ask him if he accepts my plastic?

- A few million, there are more than ten million or tens of million, you can according to their actual situation, choose a few more manufacturers, to make a choice.

- Q: I want to make a plastic lid ~ ~ big barrel gasoline barrel diameter of about 58cm ~ ~ want to own processing to use what machine? How much, approximately? Where can I sell it?Every year I have about 200 thousand orders of more than cover any kind of high efficiency ~ ~ automation machine?? Can the 2~10 million machine be satisfied? And is the maintenance cost of the machine expensive?

- I would help you estimate the lid weight about 500~600 grams, barrel diameter is 58cm, the forming area of fand 2642cm. Although the cap weight is small, but the forming area is large, in the selection of plastic injection molding machine is to be considered the largest area of injection equipment,

- Q: What material should be used for the plastic crusher screen?

- The grate below the plastic crusher is made of alloy.

Send your message to us

CMAX High Output CMAX Thin-film Crusher

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords