High Output CMAX Series Low Noise Crusher For All Types of Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1.can solve the problem of width of sheet,platesand foam coil materical.

2.this serice add a set of haul-off device,two sets of press roller,air press controller.

3.the line speed can reach 30m/min

4.capacity is higher

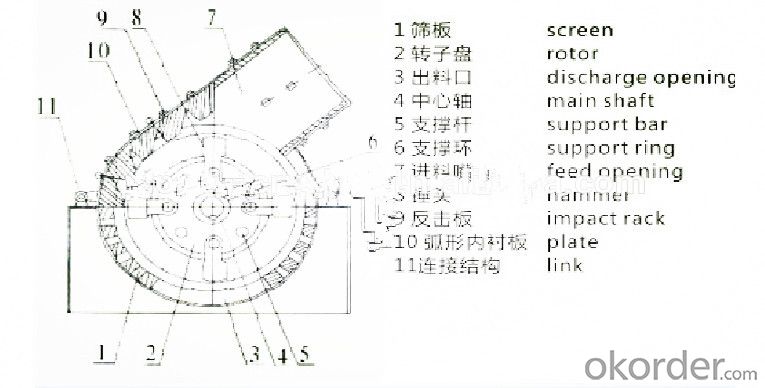

5.main axis is processed with high quality steel after verifying the balance.

6.the rotor adopts 'V''type cutting technology

7.the CMAX-FP adopts box water cooling system,which avoid sticking the blade because of the heating of materical.

8.we can provide material collection device and powder separation system according to customer's requirements

Specifications

Certification: CE SGS,ISO9001,UL,TUV

1.High capacity

2.Good quality and reasonable price

Our Services

1) Presale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Mediumsales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export

3) Aftersales service: We sent engineer to the scene to guide installation, debugging and training operators.

4) we provide engineers available to service machinery overseas

product show

technical data

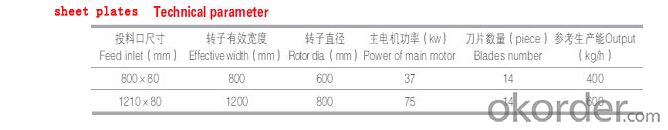

sheet plates technical

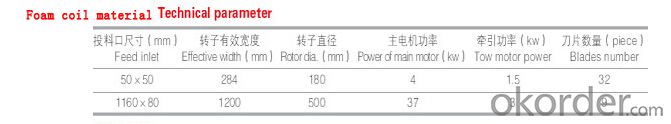

foam coil materical

FAQ:

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Plastic grinding machine mainly grinding PVC grinding material thickness of about 20 silk finger cover size, which kind of pulverizer is suitable for this purpose?

- Raymond mill mainly consists of the host, analysis machine, blower, finished cyclone separator, plumbing, motor and other components, wherein the host is composed of a machine frame, inlet volute, blade and grinding roller and grinding ring, a cover casing and a motor, auxiliary equipment, jaw crusher, bucket elevator, electromagnetic vibration feeder, electric control cabinet etc. flexible, users can choose according to the situation.

- Q: Working video of aluminium crusher

- Like cans, civil aluminum (pot bowl), aluminum plate, silk belt is aluminium, aluminum content generally below 95%, as for die casting aluminum, automobile and motorcycle parts etc.

- Q: What kind of heating machine is better for the recycled plastics factory? How long does the crusher sink need to be cleaned?

- Your shaft is broken. Is it too deep at the bottom of the bar to eat too much? The exhaust is empty and the material is normal

- Q: How many categories are there in the cutter type of plastic crushers?

- 1 、 all steel welded frame, durable2, easy disassembly design, easy cleaning and maintenance3 、 imported steel cutting tools, sharp blade, easy to change, durable4, grinding all kinds of soft and hard plastic, easy and easy5. It is equipped with motor winding and interlock protection system to ensure safe use6. The minicomputer is equipped with pulleys for easy movement. The large machine has a water cooling system for easy time operation7, you can choose different tools and different hole through the screenClaw knife plastic crusher is suitable for all kinds of plastic pieces of recycle, especially for all kinds of rigid plastic (such as material, shoe material) better.Flat knife plastic crusher

- Q: How much does it cost to process a ton of plastic bottles?

- An overview of waste mineral water bottle is a polyester plastic products currently on the market, there is no feasible method for recycling, but the crushing, washing, drying after processing into pieces of plastic, it is an important raw material for spinning, the current market price per ton up to 7000 yuan. In Shandong, some of the waste plastics market, the supply of such products in short supply, some rely on recycling processing of such plastic production households, annual income of up to 20-30 yuan. Because this kind of plastic products have four seasons, and the production is simple and convenient, so the market is very broad, suitable for investment and production throughout the country, there are generally 100 square meters of open space. Two, the configuration of the equipment and is mainly composed of 45 types of plastic crusher (with 1.5 kW motor, the yield of 400 kg / hour), washing machine (7.5 kW motor), feeding machine (4 kW motor), washing machine (3 kW motor), dryer (7.5 kW motor, yield 4000 kg / when the small five institutions)

- Q: How should the plastic crusher blade be ground?

- Plastic crusher blades generally need to grind when it is relatively blunt

- Q: Packing belt above hasp can't get rid of buy a crusher can I directly broken is broken belt

- In the recycling process of waste plastics, waste a lot of it contains a lot of iron

- Q: How often does the plastic crusher get rid of the knife?

- Bolt tooth nut is not equipped with spring washer. It is easy to loose bolts

- Q: What kind of material is used for plastic hairpin?

- The hairpin is usually made of modified or nylon plastic.See if you're satisfied

- Q: In hard rock foundation construction, can not be carried out burst, crusher does not move. Is there any good way?

- There will be a lot of smoke coming out; in such a circle, a hole about 1 meters in diameter will be formed. Then it can be built with static blasting.

Send your message to us

High Output CMAX Series Low Noise Crusher For All Types of Pipe/Sheet Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords