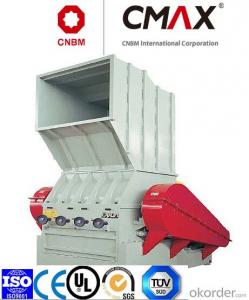

high output recycled wood plastic crusher

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

high output recycled wood plastic crusher

1. CE/ISO9001 certificate.

2. Warranty is a year(12months).

3. T/T, L/C are both accepted by our industry.

4. Testing, We can arrange the machine testing according to your requirements.

5. After-sales services: Our engineers can do the installation and testing services in your area.

6. Delivery time, our Production Department can arrange the delivery within 35days after our Account Departmen confirmed the down payments.

SWP series plastic crusher Introduction

SWP series plastic crusher is designed to crush various sorts of plastic and rubber with thermoplasticity such as plastic profile, pipe, rod, thread, film and waste rubber products. The consequent grain can be used for extrusion and injection.

Swp-400 plastic crusher is well used for reclaiming large profiles and pipes for its strong crushing capacity, high output and stable performance. Equipped with automatic material drawing machine, the automation degree of the crusher is highly improved.

The main technique parameter

| Para.⁄Model | SWP160 | SWP260 | SWP360 | SWP400 | SWP500 | SWP630 |

| Rotary blade dia. | 160 | 260 | 360 | 400 | 500 | 630 |

| Moving blade speed | 480 | 580 | 536 | 404 | 550 | 401 |

| Moving blade piece number | 3 | 3 | 3 | 5 | 12 | 3 |

| Sifter hole dia. | 8 | 10 | 10 | 12 | 10 | 12 |

| Grain size | 3-8 | 3-10 | 3-10 | 3-10 | 3-10 | 3-10 |

| Breaking capacity | 60-120 | 250-300 | 300-400 | 300-450 | 400-1000 | 700-1500 |

| Motor power | 3 | 7.5 | 11 | 15 | 22 | 30 |

- Q: 600 of the plastic crusher, there are 18 pieces of moving blades, 4 fixed blade, want to ask the blade and the fixed blade of the gap is how much?Look, the machine seems to have become smaller from left to right. Is that so?

- It requires the choice of the chemical composition of the blade material suitable for different requirements of the user and crushing different objects. It requires a suitable blade angle that keeps the edge of the blade sharp and allows the blade to have a certain strength instead of collapsing during use. It requires a good heat treatment process to achieve the blade's hardness and very little internal stress. The plastic shredder blade will not deform during use.

- Q: Plastic grinding machine mainly grinding PVC grinding material thickness of about 20 silk finger cover size, which kind of pulverizer is suitable for this purpose?

- At the same time also conducive to grind heat sensitive plastics, can be part of PE and ABS were studied by means of combination of Feng Shui cooling system of ground to make the machine run for a long time without heating. High quality wear-resistant steel cutter, good abrasion resistance. High yield, fine grinding, can be adjusted. Function between 10 -100 orders. When the power, do not need to care for a wide range,

- Q: What is the noise produced by a plastic crusher?

- Large bales of bales, bags, woven bags, rolls, paper, fibres, forklifts, pallets, etc can be effectively crushed and suitable for crushing and recycling plastics, rubber and wood.

- Q: How to dust the plastic crushing material?

- The dust filter bag is more durable, and because of the design of negative pressure type, the fan does not touch dust, so that the utility model has the advantages of stable work, higher efficiency and longer service life. Equipped with mature fan frequency conversion device, the fan of dust removal system can automatically adjust the operating conditions according to the quantity of production equipment

- Q: How much does it cost to process a ton of plastic bottles?

- Three, the production process: picking materials, impurities - crushing processing - cleaning stains - automatic feeding - rinse treatment - dry dry - packaging. Four, production cost analysis (according to production ton): 1. raw material 5000 yuan / ton + electricity 1000 yuan + wages 800 yuan, =6800 yuan. 2., the market price: 7100-6800=300 yuan 3., monthly output of 3 tons: 300*3=900 yuan 4., according to an annual output of 200 tons calculation: 200**900=180000 yuan.

- Q: Why plastic crushers are closely related to environmental protection?

- As is known to all, the decomposition of plastics is very poor. Plastic discarded, not recycled, will affect the environment. PS: we do import engineering plastics

- Q: PVC what's the best blade for plastic crushers?

- 65Mn the most common, cheap, very sharp, the drawback is not wear-resistant. Grinds the blade original, feels that gives the minute Oh!

- Q: What kind of material is used for plastic hairpin?

- With plastic injection molding, just buy plastic injection molding machines and plastic crushers

- Q: Plastic crusher is slow to eat. Why?

- The knife when the attention, it is best to wear knife, knife grinding after

- Q: Hello everyone! I am engaged in waste plastics crushing a small factory repelleting, I have a crusher is crushing all kinds of waste plastic bottles, plastic blocks and pipes, with cleaning one broken, can put the screen into big hole, and then smash PP and PE agricultural waste sacks film can be used? You have experienced elder brother to help, thank you little brother

- Plastic properties are not the same, separate cutting, pipes need relatively strong crusher, such as broken PET, because of heat will crystallize, in the process of cutting through the tear will inevitably lead to molecular damage, there is need to consult

Send your message to us

high output recycled wood plastic crusher

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords