Plastic Compression PPR Elbow 45 Degree Internal/External Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: PP-R

Technics: Forged

Type: Elbow

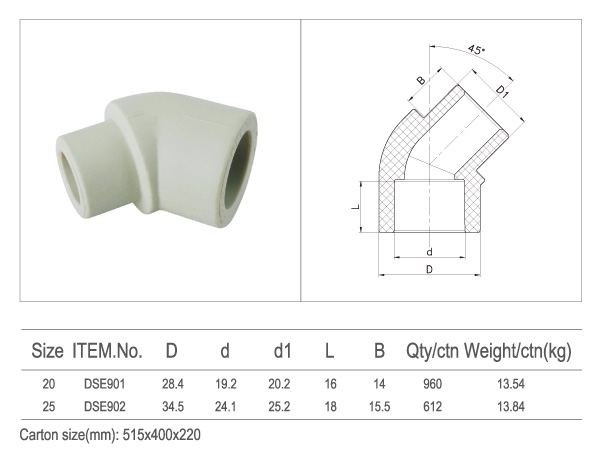

- Model Number: DSE901-902

- Connection: Welding

Shape: Equal

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~25

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 15 Days

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q: Are plastic pipe fittings suitable for marine applications?

- Yes, plastic pipe fittings can be suitable for marine applications. They are commonly used in various marine systems, such as plumbing, sewage, and cooling systems, due to their corrosion resistance, lightweight nature, and durability. Additionally, plastic fittings are often more cost-effective compared to their metal counterparts and can withstand the harsh conditions and corrosive environment found in marine applications.

- Q: Can plastic pipe fittings be used with both plastic and metal pipes?

- Yes, plastic pipe fittings can be used with both plastic and metal pipes as long as the fittings are compatible with the specific type and size of pipe being used.

- Q: Are plastic pipe fittings cost-effective?

- Yes, plastic pipe fittings are generally considered to be cost-effective. Plastic fittings are often more affordable than their metal counterparts and offer a good balance between cost and performance. Additionally, plastic fittings are lightweight, easy to install, and require minimal maintenance, which can further contribute to their overall cost-effectiveness.

- Q: What are plastic PVC pipes and pipe fittings made of?

- Raw materials: mainly PVC resin, plus impact modifier, processing aids, lubricants, stabilizers, fillers and so on, by mixing.

- Q: What are the common connecting methods for plastic PP pipes?

- The electric wire welding method: the oxidation of the tube surface skin removed, insert pipe specifications corresponding with the electric heating element, the heating element to the rated current through a certain period of time, polypropylene pipe fittings and pipe joints to heat and melt each other, turn off the power, thus forming an inseparable interface. The butt welding of the pipe end treatment method: first, with the heating plate placed on well tube and tube or pipe and pipe fittings, set the heating temperature, close the control power, heating, pumping out the heating piece, and then ends by force rapid docking together to form a high cooling. The strength of trapezoidal interface, its interface strength and bulk material. Flexible flange connection method: in the plastic flange place steel looper flange, and then put the appropriate gasket, string into the specified bolt, tighten it.

- Q: Can plastic pipe fittings be used in compressed air systems?

- No, plastic pipe fittings should not be used in compressed air systems as they are not designed to handle the high pressures and potential stress that can occur in such systems. It is recommended to use metal pipe fittings specifically designed for compressed air applications to ensure safety and reliability.

- Q: The difference between PP-R aluminum pipe and PP-R pure plastic pipe

- From the connection way, aluminum plastic pipe is a physical connection, simple and convenient, unless the operation is improper, its safety and reliability is very high. PE pipes and PP-R pipes with hot melt or welding connection, complex process, easy to produce stacking defects, lead to stress concentration, influencing the long-term performance of pipeline; in addition, the local high temperature fuse facilitates pipeline material degradation, accelerated aging pipeline

- Q: Can plastic pipe fittings be used for irrigation systems in cold climates?

- Yes, plastic pipe fittings can be used for irrigation systems in cold climates. Plastic fittings are resistant to freezing and can withstand the low temperatures typically experienced in cold climates. Additionally, plastic fittings are durable and less prone to corrosion, making them a suitable choice for irrigation systems in such environments.

- Q: Are plastic pipe fittings resistant to alkalis and acids?

- Yes, plastic pipe fittings are generally resistant to alkalis and acids.

- Q: Do plastic pipe fittings require maintenance?

- Yes, plastic pipe fittings generally do not require maintenance. They are known for their durability and resistance to corrosion, rust, and rotting. However, regular inspection is advised to ensure there are no leaks or cracks in the fittings.

Send your message to us

Plastic Compression PPR Elbow 45 Degree Internal/External Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords