PPR 45 Degree Elbow High Quality Fittings Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: Casting

Type: Elbow

Place of Origin: China (Mainland)

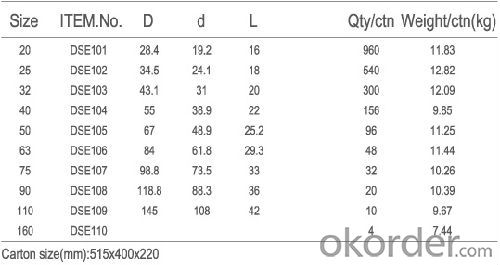

Model Number: DSE101-110

- Connection: Welding

Shape: Equal

Head Code: Round

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Size: DN20~25

Color: Green, White, Grey, Blue

Packaging & Delivery

Packaging Details: PE bag + carton

Delivery Detail: 25 Days

Specifications

Standard:DIN8077/8078

Material:R200P from Korea

Brand:Donsen

Size:DN20~160

Color:Green, White, Grey

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving.

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q:Can plastic pipe fittings be used for water desalination systems?

- Yes, plastic pipe fittings can be used for water desalination systems. Plastic fittings are commonly used in water treatment systems due to their corrosion resistance, durability, and affordability. They effectively connect and direct the flow of water in desalination systems, ensuring reliable and efficient operation.

- Q:Can plastic pipe fittings be used for sewer and wastewater systems?

- Yes, plastic pipe fittings can be used for sewer and wastewater systems. Plastic fittings, such as PVC or ABS, are commonly used in these systems due to their durability, resistance to corrosion, and ease of installation. They are also cost-effective and offer a long lifespan, making them a popular choice for sewer and wastewater applications.

- Q:How is the building material, plastic pipe and sewer made? Where are the machines and how much is the selling price?

- The plastic pipe used in different fields, they have a common characteristic is the need to withstand the pressure and impact, and in turn, the position, and sometimes need to add metal inserts, the tube wall is generally thicker, so when the injection molding production, attention must be paid to the quality of plastic plastic the temperature, pressure, and (especially the two pressure holding time long) control, speed, special machine Chun's existing UPVC, SPVC, PP-R and PE special screw, machine fittings special emission maximum (National injection amount of 43 kg, a clamping force of 2000 tons), to ensure the plasticizing quality of different plastics, in the room (such as Liansu, Gu and other companies) in the process of using well. Below to PP-R pipe production, for example, to explain the specific characteristics of the process: (1) PP-R raw material properties: raw materials generally do not need drying.

- Q:Are plastic pipe fittings resistant to UV degradation in outdoor applications?

- Yes, plastic pipe fittings are typically resistant to UV degradation in outdoor applications.

- Q:What are the disadvantages of using plastic pipe fittings?

- One of the main disadvantages of using plastic pipe fittings is their susceptibility to degradation and wear over time. Plastic fittings can become brittle and crack when exposed to extreme temperatures, sunlight, or chemicals, leading to leaks and potential water damage. Additionally, plastic fittings may not be as durable as metal ones, particularly in high-pressure applications, which can result in a higher risk of failure. Finally, plastic fittings may not be compatible with all types of pipes, limiting their versatility and use in certain plumbing systems.

- Q:Can plastic pipe fittings be used for medical gas systems?

- No, plastic pipe fittings should not be used for medical gas systems. Medical gas systems require materials that are specifically designed and approved for the purpose, such as copper or stainless steel fittings.

- Q:Can plastic pipe fittings be used for waste disposal systems?

- Yes, plastic pipe fittings can be used for waste disposal systems. They are commonly used due to their durability, corrosion resistance, and ease of installation.

- Q:Are plastic pipe fittings compatible with solvent welding?

- Yes, plastic pipe fittings are compatible with solvent welding. Solvent welding is a process of joining plastic pipes and fittings by using a solvent adhesive. The solvent softens the plastic, allowing the pipe and fitting to fuse together, creating a strong and leak-proof connection.

- Q:Can plastic pipe fittings be used for vacuum systems?

- Yes, plastic pipe fittings can be used for vacuum systems as long as they are specifically designed and rated for that purpose. It is important to choose fittings that can handle the required level of vacuum pressure to ensure safety and optimal performance of the system.

- Q:Are plastic pipe fittings resistant to UV degradation in indoor installations?

- Yes, plastic pipe fittings are typically resistant to UV degradation in indoor installations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR 45 Degree Elbow High Quality Fittings Pipe Fitting

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords