Perforated Continuous Casting Aluminum Coil for Prepainted AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

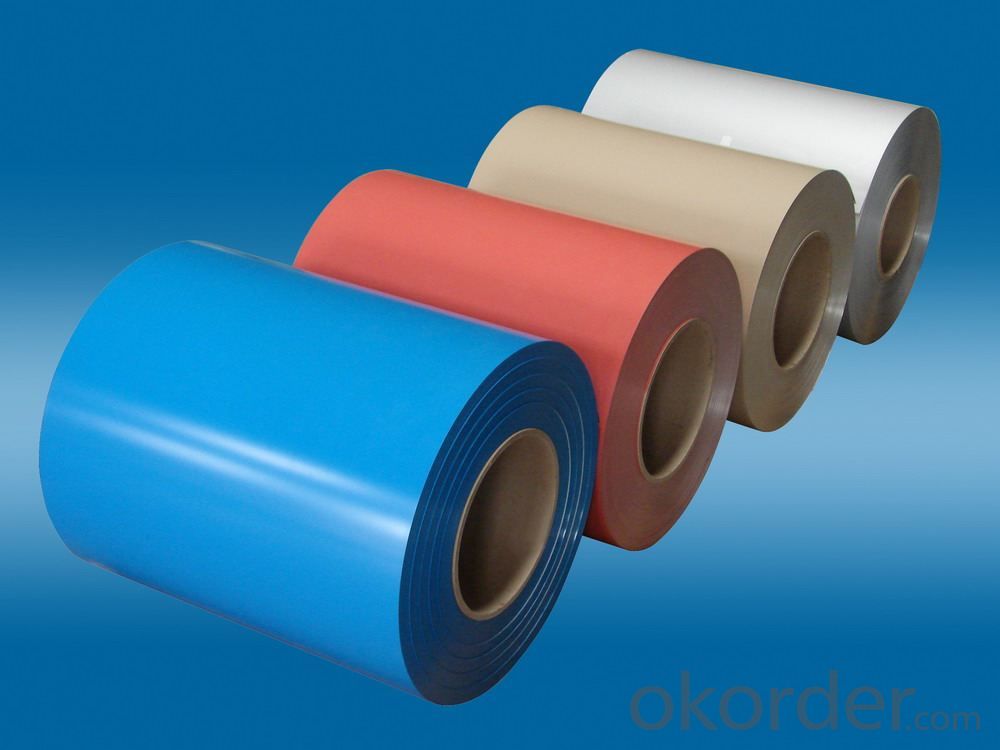

1.Structure of Continuous Casting Aluminium Coil for Prepainted AA3003

Continuous Casting Aluminium Coil for Prepainted AA3003 can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Coil for Prepainted AA3003

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA1050 | H14 | 0.2-3MM | 1000-1800MM | 2 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the main influence of the spacing?What are the main effects of spacing?

- Thermal explosion is related to a lot of factors. As to how much impact the lining board has on the thermal explosion, it's really impossible to speak of it. I think it has very little influence

- Q: As for graphite and aluminum sheet, which one has a better thermal conductivity?

- Aluminum sheet has a better thermal conductivity, because metal is good conductor of heat, graphite is n't metal.

- Q: Can aluminum sheets be used for curtain walls?

- Yes, aluminum sheets can be used for curtain walls. Aluminum is a popular choice for curtain wall systems due to its lightweight, durability, and flexibility in design. It offers excellent structural integrity, weather resistance, and thermal performance, making it suitable for creating modern and aesthetically appealing curtain wall facades.

- Q: Hi I am getting a laptop pretty soon and have pretty much decided on a Mac. But really a white macbook is $1150, and aluminum is $1400. And just so no one says this, the white one is updated with all the same hardware(Advanced graphics, etc.) I want to get it asap so the $250 would mean about 2 months longer which would kind of be a drag. I also understand the aluminum doesn't have a firewire port, but idk what the hell that even is so can someone explain what it is and why I would care about it. Basically, is it worth the 2 months and $250 for the aluminum. Thanks.

- honestly just go for the white macbook! the aluminum MB is stronger as it's a unibody (its made out of a single piece of aluminum( the but it has a load of set backs, and in the long run it could be more costly, because lets say you break or a lose a key on your keyboard, you have to replace the whole keyboard instead of just a single key. if your hard drive ever breaks down, it'll cost a crapp load to replace as you have to send your MB to apple to have them repair it (my friend paid like $800 to get it replaced). also you can't remove your battery (if it dies) and you have to have it replaced by apple once again($1000) (unless you want to do it yourself and void the warrenty). It's more costly on the aluminum to upgrade hardware (RAM, Hard Drive etc..). but on the otherhand the aluminum looks shinier :), and the screen is lit with LEDs. but aswell alot of the amlunium macbooks have problems with them like faulty nvidia graphics card, and they produce alot of heat! as for the firewire port, you kind of want that because you'll eventually buy something which will use the firewire port. it's just like a usb port except it's faster. alot of external hard drives and other storage devices, video camera's, hd camera's, some hd webcams, some musical instruments (e.g pluggin a guitar into your macbook through an external sound card.) and aswell since the white macbook is fully upgraded and has the same specs as the aluminium why not go for it? and aswell its cheaper to upgrade your RAM/Hard drive on the white MB. and you wont have to wait 2 months

- Q: I'm working on this project and I have to glue together a 4mm thick aluminum and a 5mm aluminum. It's a 17mm wide hexagon.

- Aluminum does not glue very easily. Welding is better, but if it's not for something structural any kind of Crazy Glue or Super Glue will hold it in position. It won't hold together under any kind of stress though. Alternately you could use machine screws, or self tapping screws.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring. Aluminum sheet is primarily used for structural and decorative purposes due to its lightweight and corrosion-resistant properties. However, aluminum wire, which has different characteristics and is specifically manufactured for electrical applications, can be used for electrical wiring. Aluminum wire was commonly used in the past, but due to concerns about its conductivity, durability, and potential fire hazards, it has been largely replaced by copper wire in residential and commercial electrical installations. Copper wire is preferred for its superior conductivity and lower risk of developing loose connections or overheating.

- Q: after putting aluminum sheet into the area between magnet and iron products, could magnet attract iron again?

- magnet can attract iron if the aluminum sheet isn't too thick. Because aluminum can't cut off magnetic line of force, unless aluminum sheet's thickness surpass the range of magnetic attraction.

- Q: Is it possible to use aluminum sheets in extreme weather conditions, including very hot and very cold temperatures?

- <p>Yes, aluminum sheets can be used in harsh environments, including hot and cold climates. Aluminum is known for its excellent corrosion resistance and durability, making it suitable for various weather conditions. It does not rust and maintains its strength in both low and high temperatures. However, it's important to consider the specific alloy and protective coatings used, as these can affect performance in extreme conditions. Properly treated and coated aluminum can withstand significant temperature fluctuations without significant degradation.</p>

- Q: I am ultimately looking to have a bike that is good for both everday commuting and touring with panniers/racks long distance with camping. From what I've read on the internet steel frames are more forgiving and ride smoother. The guy at my local bike shop tells me aluminum frames have more flex and ride better. I don't know if he's just trying to make a sale (Giant dealer) or to trust him, unfortunately the staff there are all just racers not tourers. If you can recommend any brands/models to check out that'd be good. From my research thus far I am in love with Co Motion bikes, just not the price! I'm looking at $1000 max for a good touring bike. Thanks!

- looks like the Americano series are equipped with tandem wheelset. That's heavy duty touring. I believe he is trying to make a sale. If aluminum flexes, then the result will be a crack. If steel decide to fail, it bends from fatigue, aluminum just snaps when it fails. Steel gives you a much noticeable warning. So...steel bends. It flexes when you put a lot of stress, but when you are touring, it's not likely your going to go all out like racers do when they pursue. Steel will absorb more of the road vibrations and shock. You might want to try a different shop if all they do is pitch Giant brand. BTW Giant is THE world largest bicycle manufacturer. They build bikes for different companies besides their own. So you never know where or what brand your really riding. There are many touring bikes out, but if you go by manufacturers then it is only limited to a few by brands. There is more options when you want a racer. Remember when choosing a touring bike to choose one with a good wheelset. I like wheels with 36 spokes or more, they take the brunt of the weight (rack, pannier, other accessories).

- Q: aluminum is produced by breaking down the compound...

- Bauxite is the most important aluminum ore. It consists largely of the minerals gibbsite Al(OH)3, boehmite γ-AlO(OH), and diaspore α-AlO(OH), together with the iron oxides goethite and hematite, the clay mineral kaolinite and small amounts of anatase TiO2. You have an unusual way of asking that question. Aluminum is an element and cannot be broken down accept to sub-atomic particles.

Send your message to us

Perforated Continuous Casting Aluminum Coil for Prepainted AA3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords