PE black and white film for aluminum composite panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 square meter m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

removable protective pe protective film manufacturer

Specifications:

1)Item: removable protective pe film manufacturer

2)Thickness:0.023mm-0.15mm

3)Width:below 1510mm

4)Length: made as order

5)Color: Blue,transparent or as customers' require

6)Printing: logo, word and picture can be printed as order

7)Adhesion: low adhesion, medium adhesion, high adhesion, and super high adhesion

8)Adhesive strength:30~500g/25mm

PE protective film Application:

Our furniture protective film can be applied on the following materials.

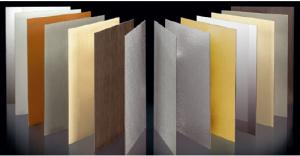

1. Metal sheet

2. Stainless steel sheet, aluminum sheet (mill finish, polished finish, brushed finish, coating finish, corona finish, anodized finish, oxidation treatment)

3. Aluminum composite panel (different surface finish)

4. Aluminum section materials (different surface finish)

5. Plastic sheet (PVC, ABS, PS, PC, PMMA)

6. Building and decoration sheet

7. Furniture

8. Architectural panel

9. Carpet

10. Automobile (interior carpet, floor, sets, lamp, door panel, hood)

Features and usage:

1. Our protective film is easy to attach and remove.

2. It leaves no residue glue or trace on the surface of material after being peeled off.

3. It can be printed with company's logo, trademark, advertising messages, technical documents, etc.

4. The protective film can protect the target surface from pollution, corrosion and scratches during production, transportation, storage and installation, etc.

- Q: How to cover the screen with protective film? What tools and skills are needed?

- 1. Wipe away the dust on the surface of the screen with the fibrous cloth attached at first. When you wipe the screen, you should wipe in the same direction. Don't do it back and forth. 2. Then determine the direction in which you will stick the film. And peel down a small part of the release film marked as "step1" and get ready to stick it. 3. When you stick the film, you should peel down a part of the release film and align it at the screen. Then stick it to the screen and tear the release film at the same time until the whole film is sticked to the screen. 4. When it's done, tear off the second layer of release film marked as "Step2" . 5. Finally completely tear off "Step2" release film. Then you can use it without worry.

- Q: Does it matter if the protecive film on the cooling fin of air conditioning is washed off?

- If the film is coated on the surface, that's hydrophilic film, used to strengthen the refrigerating effect. If it's removed when it should not be removed, then it will affect the refrigerating effect of the air conditioning. If there's a liite part of the film is washed off, it doesn't matter. But the fin is put closely to each other. You should remove the film one by one. Is the fin put closely to each other?

- Q: What are the main ingredients of the PE protective film? Is there any harm to human health?

- There are two kinds of PE protection film.One is not to use glue, it is directly extruded by polyethylene and sticky material. Known as the "self mucosa", there is no harm.Another is to glue, and generally on the acrylic glue, generally no harm.

- Q: why do some marks appear on the suface after PC+ABS specular products are coated with protective films?

- The phenomenon occurs because film is covered unevenly when some parts are perfectly coated but others are not. In such a condition, the PC+ABS material changes as the temperature and humidity change, forming bubbles. Of course, there's something to do with the glue of the protective film. If highly required, protective film must use specific glue.

- Q: What are the unique properties of PET protective film?

- Property 1: Highly adhesive, fairly sticky and anti-solvent. When used in the normal temperature environment, the sidelines of the film stay straight and no glue remains. Use: Apply to decoration and ordinary industrial sheltering. Property 2: Excellent whether resistance. Apply to use at temperature below about 150℃. No residual glue. And the boundary of color separetion is clear. Use: Apply to car color covering and industrial machinery painting. Property 3: Special PET material with high tensile strength as well as acid and alkali-resistance. No permeation and no residual glue. Use: Apply to spray paint at high temperature. The film is made from sprcific materials, making it resistant to high temperature and environmental friendly. Once coated, the film will not fall off. And no glue will remain. It's the best choice for the protection of coatings like LCD, ITO, PMMA and PC. The Hualibao company is working on protective films. You can go there to learn more about PET protective films. It is suitable for automobile color cover.

- Q: What are the materials used in the production of aluminium protective films? What's the harm to life?

- Aluminum protective film is specially formulated with polyethylene (PE) film as substrate, using polyacrylic acid (ester) resin as the main material of the pressure sensitive adhesive, with several specific help glue coated, cutting, packaging and other processes, properties of soft protective film,

- Q: Is it necessary to use PET high-temperature-resistant protective film in lithium battery?

- Generally speaking, PET high-temperature-resistant film is used to cover the surface of the battery core before the core is dried. The main function is to protect the surface of the battery core from scratches and the liquid in the battery from corrosion. The film is resistant to high temperature bacause the battery core needs to be dried at temperature of 75-85 degrees. Some PET protective film may be out of shape at that temperature. Meanwhile, there is certain requirement for the adhesion of the protective film. It can't be too sticky. Otherwise the packaging film may be torn down when you dismantle the battery. In addition, it must be ensured that the protective film won't fall off during the following processing of producing the battery core.

- Q: Why does PE film curl when rolling it after coating?

- It may happen if the temperature of equipment is too or glue of high adhesion is applied to fairly thin flim. (The solution is to increase the speed or decrease the temperature.) The adhesion of glue is too high because it's too thick, or the base material is not good, or the stress is too strong when drying the film.(Solution: using the inlet air to press the film from the right side to make it flat and ensure the glue won't fall off.) And if the film you use is composite membrane, when the composite membrane is not composited compeletly, the same problem may occur too. I don't know your coating process, thus all above are the possible reasons that I suppose.

- Q: What specifications about adhesion does PET protective film have?

- More specifically, you want to know how many degrees the adhesion of PE film can be further classified into, right?PE protective film can be devided into two types--based on static and based on glue. The static-based type is not adhesive. But as for the glue-based type, the adhesion can be further classified into degrees as follows: super low, low, ordinary, high,super high; or further classified using the unit G.

Send your message to us

PE black and white film for aluminum composite panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 square meter m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords