Aluminum Sheets for Sale Philippines - Painted Aluminum Sheet for Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

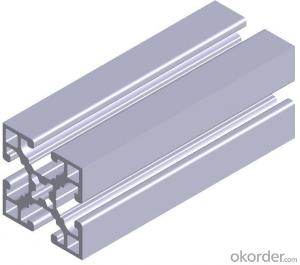

1.Structure of Painted Aluminum Sheet for Composite Panels

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Painted Aluminum Sheet for Composite Panels

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Painted Aluminum Sheet for Composite Panels Images

4.Specification of Painted Aluminum Sheet for Composite Panels

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Aluminum is dangerous when you breath high levels from the air. There is no evidence that liquids stored in aluminum cans leach in enough aluminum to have any effect at all. Quite often these sorts of rumors/assertions start with that kind of kernel of truth. Remember though, chemistry is complex. A chemical that can kill you in one state/amount is pretty harmless in another. For example, hydrogen dioxide is deadly when taken in large amounts, but it is safe in the amounts we normally drink.

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: With a project I'm working on, I need to reinforce a small case made of aluminium. My options are to use regular old screws (probably steel) or Stainless Steel screws (much more costly). Just wondering what corrosion will be like? *It will never ever get wet,* so does that mean corrosion will not occur? (to a certain degree, obviously) And would corrosion, since its dry, still be affected by the type of metal used for the screws? The screws need to be strong, and they also need to be purchase-able at a regular hardware store, as I'm not going to go buying just screws on-line. Thanks for any info you can provide.

- You don't mention just what this project is, but 'regular' screws in the aluminum will not 'rust' - but they may cause galvanic action (a white powdery aluminum oxide may form over time.) Most hardware stores carry aluminum screws, why not just buy and use them if you are concerned? They are usually used for aluminum replacement windows and may be painted white. You can use sandpaper to remove the paint if you want the silver to show.

- Q: Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes according to the requirements of the project or application.

- Q: I know that aluminum doesn't belong in the human body. As a canister to hold liquids which will be consumed later, is aluminum good or bad to use?

- Not really. Al in your diet is believed to be a cause of Alzheimer's disease. And putting acids (like fruit juice) in a bottle would definitely corrode the metal somewhat; water is slower but there is a taste that means that some Al is going in. Thus many (most/all?) Al bottles are lined in plastic and have plastic closures. Stainless steel with a stainless steel closure are a much better choice than Al. But they are harder to find and often more expensive. Stainless steel with polyprop. closures but not plastic lined are easier to find (but less durable; I am forever breaking off the poly tabs). Of course Al bottles are better than plastic bottles.

- Q: Are aluminum sheets suitable for food processing applications?

- Yes, aluminum sheets are suitable for food processing applications. Aluminum is known for its excellent thermal conductivity and corrosion resistance, making it ideal for food industry processes such as cooking, baking, and packaging. Additionally, aluminum is a lightweight and cost-effective material that can be easily formed into various shapes and sizes, making it convenient for food processing equipment and utensils.

- Q: Are the aluminum sheets suitable for signage or advertising purposes?

- Aluminum sheets are an excellent choice for signage and advertising purposes due to their high suitability. The versatility and durability of aluminum make it resistant to rust, corrosion, and weathering, which is ideal for outdoor use. Furthermore, its lightweight nature facilitates effortless installation and transportation, while the smooth surface adds a touch of professionalism and sophistication. The customizable nature of aluminum sheets allows for easy cutting, shaping, and engraving, enabling designers to create captivating signs and advertisements. Additionally, aluminum sheets can be directly printed on or laminated with vinyl to achieve vibrant and long-lasting graphics. In summary, the remarkable properties of aluminum make it the perfect material for signage and advertising purposes.

- Q: Can aluminum sheets handle high temperatures?

- Yes, aluminum sheets can handle high temperatures. Aluminum has a high melting point of 1220°F (660°C) and excellent heat transfer properties, making it suitable for various applications that involve exposure to high temperatures.

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, the process of painting aluminum sheets may require some preparation to ensure proper adhesion and durability of the paint. The most important step is to clean the surface of the aluminum sheet thoroughly to remove any dirt, grease, or corrosion. This can be done using a mild detergent and water or a specialized aluminum cleaner. After cleaning, the surface should be dried completely before painting. To improve the paint adhesion, it is recommended to apply a primer specifically designed for use on aluminum. The primer will create a bond between the aluminum surface and the paint, ensuring better adhesion and longevity of the paint job. After the primer has dried, a suitable paint can be applied to the aluminum sheet. It is important to choose a paint that is compatible with aluminum and provides good adhesion and weather resistance. Acrylic or epoxy-based paints are commonly used for painting aluminum. Before painting, it is advisable to test a small inconspicuous area to ensure that the paint adheres properly and achieves the desired finish. Additionally, it is important to follow the manufacturer's instructions for the specific paint and primer being used, including proper drying times and application techniques. Overall, while aluminum sheets can be painted, it is essential to properly prepare the surface, use suitable primer and paint, and follow the recommended procedures to achieve a durable and aesthetically pleasing paint finish.

- Q: What are the typical uses or applications for 101 aluminum sheets?

- 101 aluminum sheets are commonly used in a variety of applications such as roofing, siding, gutters, and general construction due to their excellent corrosion resistance, high formability, and durability. They are also utilized in the automotive industry for body panels, trims, and interior components. Additionally, 101 aluminum sheets are often used for packaging, electrical enclosures, and kitchen equipment due to their lightweight nature and ability to withstand various environmental conditions.

Send your message to us

Aluminum Sheets for Sale Philippines - Painted Aluminum Sheet for Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords