Online Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Low-E Glass is coated with low-E material-Silver, other low-E materials and metallic compound film over the surface of the glass, making the glass’s emissivity reducing from 0.84 to below 0.15. It not only has excellent energy efficiency, but also has decorative effects because of colors, and meanwhile has good processability (easy to be tempered, heat-strengthened, bent, insulating, laminated, etc.), thus becoming the first choice of architectural design. Theory for Energy Efficiency: By decreasing the U-value of glass and selectively lower the shading coefficient (Sc), It enables us to enhance the energy efficiency all sidedly.

Features:

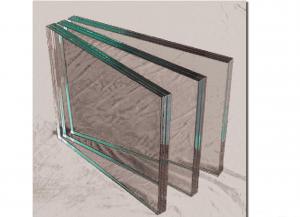

According to the performance indexes, Low-E glass can be classified as single silver Low-E glass, double silver Low-E glass, treble silver Low-E glass

Single silver low-E glass: with higher visible light transmittance and extremely high far infrared reflectance as well as good cold and heat insulation, it is applicable to both the southern areas and the northern ones

Double silver low-E glass: it is high-end low-E glass with higher visible light transmittance and extremely low solar energy transmittance

It is applicable to the commercial buildings with high energy consumption and the glass doors of refrigerators and freezers

Treble Silver Low-E Glass: with lower shading coefficient, it has a stronger restrictive effect on the solar infrared thermal energy than double silver low-E glass. It is the top-grade glass in the field of energy efficiency and only applicable to the special regions with extreme weather (cold or hot) and particular requirements. It has the best energy efficiency, comfortableness and decorative effect.

Specifications:

Thickness: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm and 19mm

Size:

2540 x 3300mm

2134 x 3300mm

2134*3600mm

2440 x 3660mm

6000 x 3300mm

12000 x 3300mm

Customized sizes

Applications:

Lowe-E Glass is widely used in glass curtain walls, energy-saving glass doors and windows because of its natural appearance and high transmittance. It is usually processed into insulating glass, the metal oxide coating contributes to the thermal insulation of windows and doors. In winter, silver coatings will reflect heat back to the interior of the building to prevent heat loss; In summer, silver coatings will reduce the re-radiation of heat to make the interior of the building cooler.

Due to its excellent thermal insulation, Low-E Glass can also be used in the fields such as ovens, refrigerator doors, wine cabinets, beverage cabinets, disinfection cabinets and other cabinets.

- Q: How is the glass made?

- The shape of each vessel is irregular. It is shining like a holy lotus under the light. It was introduced that the vessel was blown through a wooden mold. In the 30s of the last century, Artaud also successfully designed many glassware, this free form of utensils is still in production, has become one of Artaud's masterpiece.

- Q: What is the difference between FRP and carbon fiber?

- Carbon fiber (carbon fiber, referred to as CF) is a new kind of fiber material with high strength and high modulus fiber with carbon content of more than 95%. It is a flaky graphite, microcrystalline and other organic fibers stacked along the axial direction of the fiber, obtained by carbonization and graphitization of microcrystalline graphite material. Carbon fiber "an hand in a velvet glove lighter than aluminum," the quality, but the strength is higher than that of steel, and has the characteristics of corrosion resistance, high modulus, in the national defense and civilian areas are important materials. It has not only the intrinsic characteristics of carbon materials, but also the softness and processability of textile fibers. It is a new generation of reinforced fiber.

- Q: Does anyone know iPhone's toughened glass production process? Thank you

- The first special glass raw materials used for Corelle Corning, Gorilla Glass or AGC Dragontrail Glass (Asahi; if you need a AR antireflection coating processing, processing)

- Q: What kind of glass material is used in the aquarium?

- Toughened glassToughened glass is a kind of high strength safety glass which is heated by glass to softening point and then cooled rapidly. Under the same thickness, the flexural strength of tempered glass is 4-5 times higher than that of ordinary glass, and the impact strength is 5 times higher than that of ordinary glass. Toughened glass has a strong thermal stability and can withstand severe temperature changes without damaging it. The most important feature of tempered glass is safety. This kind of glass is broken into similar honeycomb particles, so it can avoid the harm to human body. Note: after tempering, the glass can not be cut, drilled, slotted and so on. Because glass is broken into honeycomb like particles that are completely irreparable, it is not recommended for use on aquariums!

- Q: What is inorganic glass?Want to be a fish tank, where can I find inorganic glass?

- Inorganic glass is quartz (SiO2) glass. Its toughness and strength are better than that of organic glass, but inorganic glass has good corrosion resistance and high temperature resistance. It is superior to plexiglass

- Q: What raw material is the front bumper of the car made of?

- Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.. Notice that it is different from fiberglass.

- Q: What is quartz made of?

- Applications and uses of 1 quartz glass, flat glass, float glass, glass (glass jar, glass bottle, glass tube), the main raw material of optical glass, glass fiber, glass, conductive glass, glass cloth and anti ray special glass 2, ceramics and refractories embryo material and porcelain glaze, the furnace with high silica, ordinary brick raw materials such as silicon carbide 3, metallurgical silicon metal, ferrosilicon alloy and silicon Aluminum Alloy and other raw materials or additives, flux

- Q: FRP process piping manufacturing process?

- The glass fiber reinforced plastic lining layer and the glass fiber reinforced plastic secondary lining layer have the function of corrosion prevention and seepage prevention, and the winding layer takes on the strength and the rigidity function of the pipeline, and the outer protective layer has the function of resisting aging, corrosion prevention and anti Japanese sun.

- Q: What kind of film is toughened glass film?

- PP materialPP protective film material is first appeared in the market, the chemical name is polypropylene, no adsorption capacity, generally use glue to stick, tear after the glue will leave marks on the screen, the screen for a long time will be corrosion. This material has been basically eliminated by the vast number of protective membrane manufacturers, but some roadside stalls are still selling, we should pay attention to!

- Q: What's the connection between tempered glass and float glass?

- Tempered glass will float glass cutting, grinding, drilling, backward tempering furnace heating to glass softening point, rapid and uniform cooling, change the compressive stress of glass, a mechanical properties of good glass products

1. Manufacturer Overview

| Location | Hunan,China |

| Year Established | 2005 |

| Annual Output Value | |

| Main Markets | Southeast Asia;Mid-East |

| Company Certifications | ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 9333,333 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Online Low-E Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords