Quilted Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

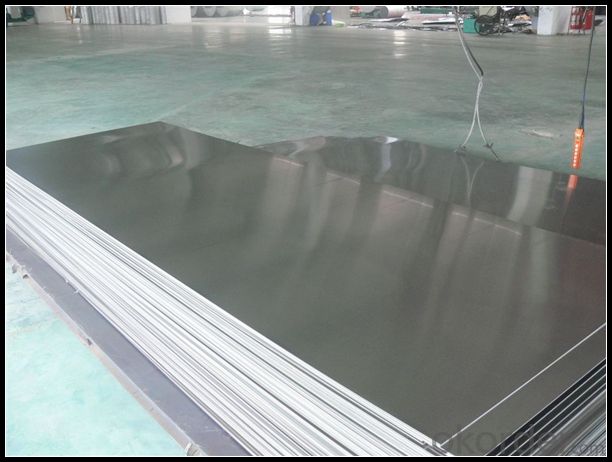

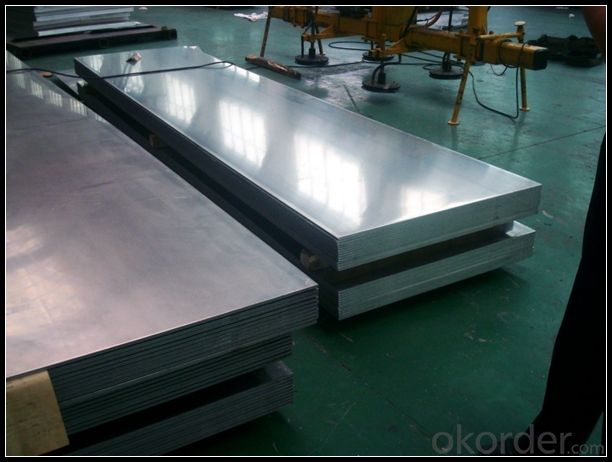

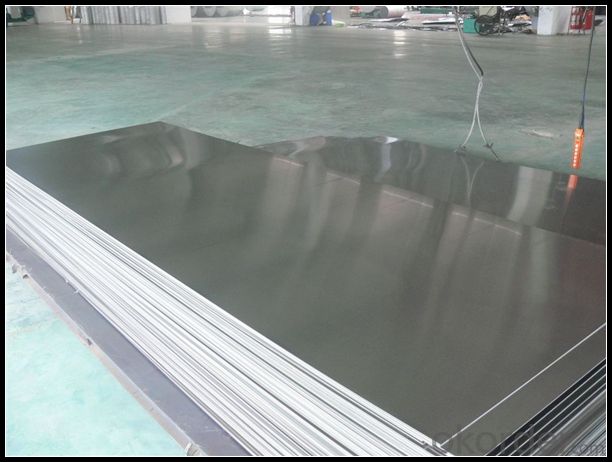

5. Image of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

6. Package and shipping of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Certainly! Nameplates or tags can be produced using 101 aluminum sheets. The durability, lightweight nature, and corrosion resistance of aluminum make it a popular material choice for such items. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability. This makes it suitable for various manufacturing processes like stamping, engraving, or etching. It can be easily cut, shaped, and customized to create nameplates or tags with clear and precise markings. Moreover, aluminum's ability to withstand harsh environments and its appealing appearance make it preferred across industries like automotive, aerospace, electronics, and signage. Hence, 101 aluminum sheets are a suitable material for producing nameplates or tags.

- Q: I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- No. In fact, aluminum (and I believe tin) work harden when hammered - as do brass and copper and you heat to anneal and then you can cool fast or slow, still soft. Tin has a very low melting point and hitting it with a torch, especially if thin, will probably put a hole in it. The chances of you actually having tin sheet metal are very low - tin cans are zinc plated steel or some other coating. Steel does harden when quench, but heating tin or zinc coated metal is likely to damage the coating and perhaps give off noxious fumes - especially zinc.

- Q: What are the disadvantages of using aluminum sheets?

- One major disadvantage of using aluminum sheets is their relatively low strength compared to other materials like steel. This can limit their application in certain industries or environments where high structural integrity is required. Additionally, aluminum sheets are prone to corrosion, especially when exposed to certain chemicals or salty environments, which can reduce their lifespan and durability. Lastly, aluminum sheets can be more expensive than other materials, making them less cost-effective for certain projects or budgets.

- Q: Describe the process of selecting an appropriate color for an exterior wall made from aluminum sheets.

- <p>Choosing a suitable color for an exterior wall made of aluminum sheets involves considering several factors. First, think about the architectural style and the existing color scheme of the building. Neutral colors like white, gray, or beige are versatile and can complement most designs. Consider the local climate; lighter colors reflect heat and are suitable for hot climates, while darker colors can absorb heat, making them ideal for cooler regions. Factor in the environment and surroundings; colors that blend with the natural landscape can create a harmonious look. Additionally, consider the maintenance and durability of the color, as some may fade or show dirt more easily. Finally, consult with an architect or designer for professional advice tailored to your specific project.</p>

- Q: Are the aluminum sheets suitable for signage or advertising purposes?

- Aluminum sheets are an excellent choice for signage and advertising purposes due to their high suitability. The versatility and durability of aluminum make it resistant to rust, corrosion, and weathering, which is ideal for outdoor use. Furthermore, its lightweight nature facilitates effortless installation and transportation, while the smooth surface adds a touch of professionalism and sophistication. The customizable nature of aluminum sheets allows for easy cutting, shaping, and engraving, enabling designers to create captivating signs and advertisements. Additionally, aluminum sheets can be directly printed on or laminated with vinyl to achieve vibrant and long-lasting graphics. In summary, the remarkable properties of aluminum make it the perfect material for signage and advertising purposes.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot varies depending on the thickness of the sheet. On average, aluminum sheets weigh around 0.96 pounds per square foot.

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q: Can aluminum sheet be anodized?

- Yes, aluminum sheet can be anodized. Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, enhancing its durability, corrosion resistance, and aesthetic appeal.

- Q: Are aluminum sheets suitable for use in HVAC (heating, ventilation, and air conditioning) systems?

- Yes, aluminum sheets are suitable for use in HVAC systems. They offer several advantages such as high thermal conductivity, corrosion resistance, and lightweight nature, making them ideal for efficient heat transfer and durability in HVAC applications.

Send your message to us

Quilted Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords