Color Coated Aluminum Coil - Mill Finish Aluminum 3003 H14 China Factory Direct Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

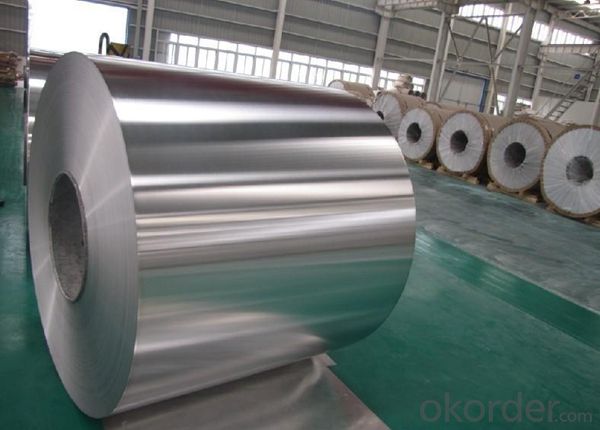

5. Image of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

6. Package and shipping of Mill Finish Aluminum 3003 H14 China Factory Direct Supply

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for methods to determine the age of an aluminum coil, distinguishing between new and old.

- <p>To determine if an aluminum coil is new or old, you can look for several indicators: the surface condition, such as scratches or signs of wear; the quality of the protective coating, if any, which may degrade over time; the manufacturing date or batch number, if available; and the overall appearance and shine. New coils typically have a smooth, shiny surface with no significant scratches or dents, and a consistent protective coating. Old coils may show signs of oxidation, discoloration, or other forms of degradation. Additionally, testing the coil's physical properties, such as tensile strength, can provide clues about its age, as these properties can degrade over time.</p>

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications. Aluminum is known for its excellent thermal conductivity, which means it is highly effective in transferring heat. Aluminum coils are commonly used in various heat transfer applications such as air conditioning systems, refrigeration units, and heat exchangers. The lightweight and corrosion-resistant properties of aluminum also make it a popular choice for these applications. Additionally, aluminum coils can be easily shaped and formed, allowing for efficient heat transfer in complex systems.

- Q: I own a pistol with an aluminum frame. If I were to store it away for a long time, would I need to bother wiping oil over the aluminum surfaces in addition to the steel surfaces? If it helps, there is a dark grey sort of finish on the aluminum.

- It matters! All metal corrodes! I don't care what others say because they don't know. Wipe down your gun good and put a good heavy oil or Break free CLP on them and place them in a good sock protector or sealed case in a cool climate controlled dry place with some moisture packs inside.

- Q: What is the cost of aluminum coils?

- The cost of aluminum coils can vary depending on factors such as size, thickness, quality, and market conditions. It is best to check with suppliers or conduct market research to get an accurate and up-to-date cost of aluminum coils.

- Q: What are the different coil handling options available for aluminum coils?

- Aluminum coils have several options for handling, depending on the user's preferences and specific requirements. Some commonly used options include: 1. Coil Cradles: These are horizontal racks or frames that provide support and stability for aluminum coils during storage or transportation. They come in various sizes and designs to accommodate different coil dimensions. 2. Coil Cars: These mobile platforms have lifting mechanisms to easily move aluminum coils between different processing stations. They can be manually operated or automated, depending on the desired level of automation. 3. Coil Turnstiles: These rotating devices hold multiple coils vertically, allowing for easy access to individual coils without heavy lifting or rearranging. They are ideal for high-volume production environments that require quick coil changeovers. 4. Coil Upenders: Specialized equipment used to rotate or flip aluminum coils to change their orientation. They are useful for loading or unloading coils in a vertical position or for specific processes that require a particular coil orientation. 5. Coil Lifters: Specifically designed lifting devices for aluminum coils. They have adjustable arms or clamps to securely grip the coil for safe and efficient lifting. Available in manual, semi-automatic, and fully automated models. 6. Coil Tippers: Used to tilt or incline aluminum coils for various purposes such as coil feeding or inspection. They can be operated manually or powered by hydraulic or pneumatic systems. 7. Coil Stackers: Used to neatly stack and store aluminum coils vertically. They have adjustable arms or forks to accommodate different coil sizes, optimizing storage space and ensuring easy access when needed. These examples showcase the variety of coil handling options available for aluminum coils. Each option has its own advantages and suitability for different applications or industries. Careful consideration of specific requirements and constraints is essential when selecting the most appropriate coil handling solution.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: What are the potential risks of using aluminum coils in specific applications?

- The potential risks of using aluminum coils in specific applications include corrosion, especially in environments with high humidity or acidic conditions. Aluminum coils are also more susceptible to damage and denting compared to other materials. Additionally, aluminum coils may have lower heat transfer capabilities, which could affect the efficiency of certain applications.

- Q: i have a project that requires me to know how safeway aluminum foil is made. i researched it on the internet, and also called safeway for it. they never gave me an answer. same for the diamond aluminum foil.please help!!!!i just need to know where they make it, how thick it is, and/or information about the ingots (such as size)and also temp. of heating room

- I'd okorder /... and they have some things on sheet as well. Something that neither covers is the lamination process, wherein the aluminum foil is coated with an organic layer (a really thin layer of plastic) to keep the metallic taste out of the food that it contacts. I believe that different companies have different ways of applying the coatings, but I'd bet they're all some variant of dip, brush, or spray followed by a heat cure. Good luck on your project!

- Q: and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q: Is it possible to use a welding torch for joining steel coils?

- <p>Yes, you can use a welding torch to weld steel coils together. However, it's important to choose the right type of welding process suitable for the specific steel grade and the desired strength of the joint. Common methods include gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW). Ensure you follow safety protocols, use appropriate protective gear, and have a good understanding of the welding process to achieve strong, reliable welds.</p>

Send your message to us

Color Coated Aluminum Coil - Mill Finish Aluminum 3003 H14 China Factory Direct Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords