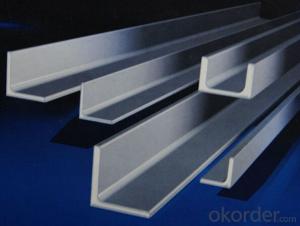

Mild Steel Prime Hot Rolled Angle Bar Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Mild Steel Prime Hot Rolled Angle Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild Steel Prime Hot Rolled Angle Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Mild Steel Prime Hot Rolled Angle Steel are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

EQUAL ANGLES SIZES | |||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Q4: what is the difference between actual weight and theoretical weight?

A4: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

Images:

- Q: Are steel angles available in different alloys?

- Yes, steel angles are available in different alloys.

- Q: What are the common standards and specifications for steel angles?

- The common standards and specifications for steel angles vary depending on the application and the country in which they are being used. However, some widely recognized standards and specifications include: 1. ASTM A36/A36M: This is a standard specification for carbon structural steel, including steel angles. It covers shapes such as angles, channels, and beams, and specifies the chemical composition, mechanical properties, and other relevant requirements. 2. ASTM A529/A529M: This specification covers high-strength carbon-manganese steel shapes, including angles, used in construction. It provides requirements for chemical composition, mechanical properties, and other important characteristics. 3. ASTM A572/A572M: This specification covers high-strength low-alloy structural steel shapes, including angles. It specifies the chemical composition, mechanical properties, and other relevant requirements for these shapes used in construction applications. 4. EN 10056: This European standard specifies the tolerances on shape, dimensions, and mass of hot-rolled structural steel equal and unequal angles. It provides requirements for the chemical composition, mechanical properties, and other characteristics of steel angles. 5. JIS G3192: This Japanese industrial standard specifies the dimensions, mass, and tolerances for hot-rolled steel sections, including angles. It sets forth the requirements for chemical composition, mechanical properties, and other relevant specifications. These are just a few examples of the commonly used standards and specifications for steel angles. It is important to consult the specific regulations and standards applicable to the region and application in order to ensure compliance and meet the desired requirements.

- Q: What are the advantages of using steel angles over other materials?

- Using steel angles offers several advantages over other materials. Firstly, steel angles are renowned for their superior strength and durability. Steel is an exceptionally robust material capable of withstanding heavy loads and extreme weather conditions. As a result, steel angles are ideal for critical structural applications, such as building construction and bridge supports, where strength and stability are paramount. Secondly, steel angles provide excellent design and fabrication versatility. They can be effortlessly cut, welded, and shaped into various sizes and forms, allowing for customized solutions that perfectly match specific project requirements. This adaptability makes steel angles suitable for a wide range of applications, including frameworks, support brackets, and reinforcements. Furthermore, steel angles possess high corrosion resistance. Steel inherently resists rusting and can be further shielded through diverse coatings or galvanization processes. This corrosion resistance ensures the long lifespan and low maintenance of steel angles, making them a cost-effective choice in the long run. Additionally, steel angles offer a remarkable level of fire resistance. Steel does not burn or contribute to fire propagation, making it particularly valuable in applications where fire safety is a concern, such as building structures or industrial facilities. Lastly, steel angles are readily available and cost-effective. Steel is one of the most widely utilized materials in the construction industry and can be easily obtained in various sizes and grades. The abundance of steel makes it an economical option, especially when compared to alternative materials with limited availability or higher manufacturing costs. In conclusion, the advantages of using steel angles encompass their strength, versatility, corrosion resistance, fire resistance, and cost-effectiveness. These characteristics establish steel angles as the preferred choice for numerous construction and structural applications.

- Q: Can steel angles be used for manufacturing bike racks?

- Yes, steel angles can be used for manufacturing bike racks. Steel angles provide strength and stability required to support the weight of bicycles and withstand outdoor conditions.

- Q: How do steel angles contribute to the energy efficiency of a building?

- Steel angles can contribute to the energy efficiency of a building by providing structural support and reducing thermal bridging. They can be used to create a strong frame, which allows for larger windows and better natural lighting, reducing the need for artificial lighting during the day. Additionally, steel angles can be used as a barrier to prevent heat transfer between different building materials, minimizing heat loss or gain.

- Q: Can steel angles be used for shelving units?

- Yes, steel angles can be used for shelving units. Steel angles are commonly used in construction and industrial applications due to their strength and durability. They provide excellent structural support and can withstand heavy loads, making them ideal for shelving units that need to hold a significant amount of weight. Additionally, steel angles are versatile and can be easily customized to fit various shelving designs and configurations. Whether for home, office, or commercial use, steel angles are a reliable choice for creating sturdy and long-lasting shelving units.

- Q: Can steel angles be used in curtain wall systems?

- Certainly, curtain wall systems can incorporate steel angles. Typically, in such systems, steel angles function as support brackets or mullions. These angles offer structural stability and reinforcement for the glass panels or other types of cladding materials. It is possible to customize the sizes and shapes of steel angles to suit the specific design needs of the curtain wall system. Moreover, welding or bolting steel angles together allows for the creation of the desired framework for the curtain wall. In conclusion, steel angles present a robust and dependable choice for integration into curtain wall systems.

- Q: Can steel angles be used for bracing?

- Certainly! Bracing can be achieved using steel angles. These angles are widely employed in construction and engineering ventures to furnish structural support and reinforcement. Their versatility allows for effortless welding or bolting, rendering them adaptable to diverse applications, including bracing. Owing to their inherent strength and rigidity, steel angles excel at bestowing stability and withstanding lateral forces. They are frequently utilized to brace columns, beams, and other structural components, thereby augmenting the overall robustness and stability of the edifice.

- Q: Can steel angles be used in shelving systems?

- Indeed, shelving systems can incorporate steel angles. It is quite common to utilize steel angles in shelving systems due to their ability to offer structural reinforcement and ensure stability. They can function as brackets or frames that securely hold the shelves in position. Steel angles are recognized for their robustness and resilience, rendering them ideal for shelving applications that involve heavy-duty purposes. Moreover, they are accessible in diverse dimensions and gauges, enabling flexibility and adaptability in shelving design. In general, steel angles are highly favored in shelving systems owing to their strength, stability, and capacity to endure substantial loads.

- Q: How do steel angles perform in terms of energy efficiency?

- Steel angles can be an energy-efficient option depending on their design and application. The energy efficiency of steel angles primarily depends on factors such as the type and thickness of the steel used, the manufacturing process employed, and the installation techniques. One aspect that contributes to the energy efficiency of steel angles is their thermal conductivity. Steel, being a conductive material, can transfer heat quickly, which can be advantageous in certain applications. For instance, steel angles can efficiently conduct heat away from building components in cooling systems, helping to maintain desired temperature levels and reduce energy consumption. Furthermore, steel angles can be designed to optimize their structural performance, reducing the need for additional materials or construction methods. This can result in lower energy usage during the manufacturing and installation processes. Additionally, steel angles can be recycled, making them an environmentally friendly choice. The energy required to recycle steel is significantly lower compared to producing it from raw materials. This reduces the energy demand and greenhouse gas emissions associated with steel production. However, it is important to note that the overall energy efficiency of steel angles also depends on their application and the overall design of the structure. Proper insulation, sealing, and design considerations are crucial to ensure optimal energy efficiency. It is recommended to consult with professionals and engineers to determine the most efficient use of steel angles in specific projects. In conclusion, steel angles can offer energy-efficient solutions when used appropriately. By considering factors such as thermal conductivity, structural optimization, and recyclability, steel angles can contribute to reducing energy consumption and promoting sustainability in various applications.

Send your message to us

Mild Steel Prime Hot Rolled Angle Bar Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords